Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rigging and Controls Aircraft Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

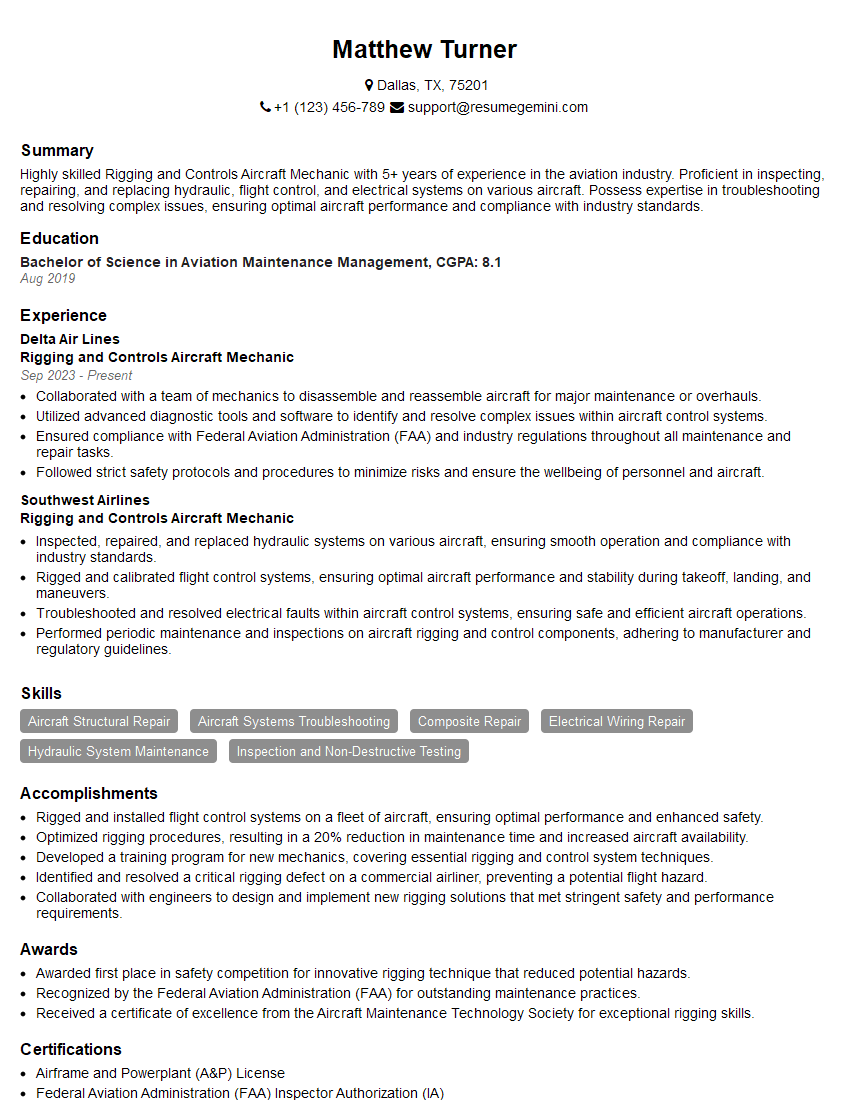

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rigging and Controls Aircraft Mechanic

1. What is the most common type of rigging used in aircraft?

The most common type of rigging used in aircraft is wire rope rigging. Wire rope rigging is strong, flexible, and durable, making it ideal for use in a variety of applications, including:

- Flight control systems

- Landing gear systems

- Hydraulic systems

- Electrical systems

2. What are the different types of wire rope used in aircraft rigging?

Types of wire rope used in aircraft rigging

- Galvanized steel wire rope

- Stainless steel wire rope

- Monel wire rope

- Inconel wire rope

Galvanized steel wire rope

- Most common type of wire rope used in aircraft rigging

- Strong, flexible, and durable

- Resistant to corrosion

Stainless steel wire rope

- More corrosion-resistant than galvanized steel wire rope

- Stronger than galvanized steel wire rope

- More expensive than galvanized steel wire rope

Monel wire rope

- Even more corrosion-resistant than stainless steel wire rope

- Stronger than stainless steel wire rope

- More expensive than stainless steel wire rope

Inconel wire rope

- Most corrosion-resistant type of wire rope

- Strongest type of wire rope

- Most expensive type of wire rope

3. What are the different types of wire rope fittings used in aircraft rigging?

The different types of wire rope fittings used in aircraft rigging include:

- Thimbles

- Turnbuckles

- Clevises

- Shackles

- Wire rope clips

4. What are the different types of control systems used in aircraft?

The different types of control systems used in aircraft include:

- Mechanical control systems

- Hydraulic control systems

- Electrical control systems

- Fly-by-wire control systems

5. What are the different types of flight control surfaces?

The different types of flight control surfaces include:

- Ailerons

- Elevators

- Rudder

- Flaps

- Slats

- Spoilers

6. What are the different types of landing gear systems?

The different types of landing gear systems include:

- Fixed landing gear systems

- Retractable landing gear systems

7. What are the different types of hydraulic systems used in aircraft?

The different types of hydraulic systems used in aircraft include:

- Open-center hydraulic systems

- Closed-center hydraulic systems

8. What are the different types of electrical systems used in aircraft?

The different types of electrical systems used in aircraft include:

- DC electrical systems

- AC electrical systems

9. What are the different types of fly-by-wire control systems?

The different types of fly-by-wire control systems include:

- Analog fly-by-wire control systems

- Digital fly-by-wire control systems

10. What are the different types of aircraft maintenance checks?

The different types of aircraft maintenance checks include:

- A-checks

- B-checks

- C-checks

- D-checks

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rigging and Controls Aircraft Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rigging and Controls Aircraft Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rigging and Controls Aircraft Mechanics maintain, service, and repair rigging and control systems on aircraft, such as flight controls, landing gear, and hydraulic systems. They also perform scheduled maintenance and inspections on aircraft to ensure that they are safe and in good working order.

1. Perform maintenance and repairs on aircraft rigging and control systems

This may include inspecting and testing components, replacing worn or damaged parts, and adjusting or calibrating systems as needed.

- Inspect and test flight controls, landing gear, and hydraulic systems

- Replace worn or damaged parts

- Adjust or calibrate systems as needed

2. Conduct scheduled maintenance and inspections on aircraft

This may include checking fluid levels, greasing components, and inspecting for signs of wear or damage. Also includes performing scheduled maintenance and inspections on aircraft in accordance with established procedures.

- Check fluid levels

- Grease components

- Inspect for signs of wear or damage

3. Troubleshoot aircraft rigging and control system problems

This may require using diagnostic equipment to identify the source of the problem and taking corrective action.

- Use diagnostic equipment to identify the source of the problem

- Take corrective action

4. Follow all applicable safety regulations and procedures

This may include wearing proper safety gear, following lock-out/tag-out procedures, and using hazardous materials safely.

- Wear proper safety gear

- Follow lock-out/tag-out procedures

- Use hazardous materials safely

Interview Tips

Rigging and Controls Aircraft Mechanics are in high demand, so it is important to present yourself well in an interview. Here are some tips on how to ace your interview:

1. Research the company and the position

This will help you to understand the company’s culture and the specific requirements of the position. You can find information about the company on their website or through online job boards.

- Visit the company’s website

- Read online job boards

2. Practice your answers to common interview questions

There are a number of common interview questions that you may be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Practice answering common interview questions

- Deliver your answers confidently and concisely

3. Bring a portfolio of your work

If you have any examples of your work, such as photos of aircraft you have worked on or certificates of completion, bring them to your interview. This will help the interviewer to see your skills and experience firsthand.

- Bring a portfolio of your work

- Show the interviewer your skills and experience

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Dress professionally

- Arrive on time

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rigging and Controls Aircraft Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.