Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rigging Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

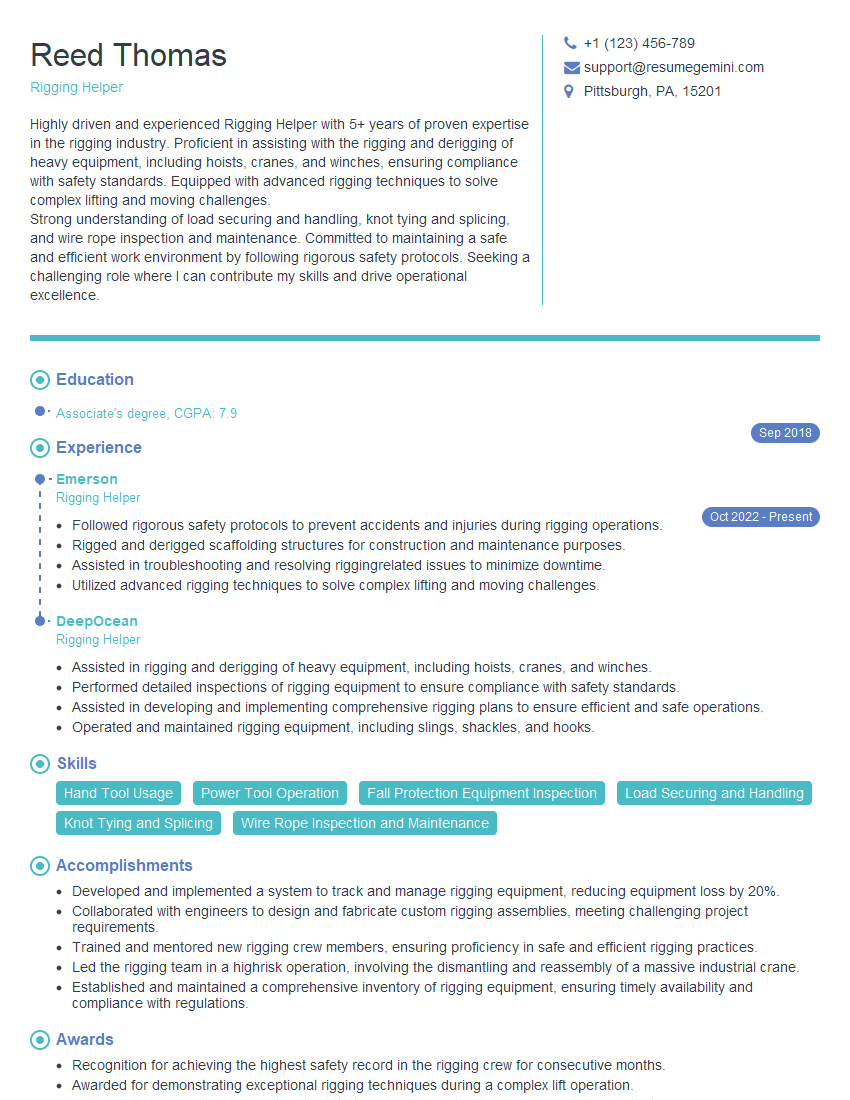

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rigging Helper

1. Explain the different types of rigging equipment you have used and the purpose of each?

I have worked with a variety of rigging equipment, including slings, shackles, hooks, and winches. Each type of equipment has a specific purpose and is designed for a particular application:

- Slings: Slings are used to lift and move loads. They are made of different materials, such as wire rope, nylon, or polyester, and come in various sizes and capacities.

- Shackles: Shackles are used to connect slings to hooks or other rigging equipment. They are made of steel or aluminum and come in a variety of sizes and shapes.

- Hooks: Hooks are used to attach slings to loads. They are made of steel or aluminum and come in a variety of sizes and shapes.

- Winches: Winches are used to pull or lift loads. They are powered by electric motors or hydraulics and come in a variety of sizes and capacities.

2. What are the safety precautions that must be taken when working with rigging equipment?

When working with rigging equipment, it is important to take the following safety precautions:

- Inspect the equipment before use: Always inspect the equipment before use to ensure that it is in good condition and free of any defects.

- Use the proper equipment for the job: Use the proper equipment for the job and never overload it.

- Follow the manufacturer’s instructions: Always follow the manufacturer’s instructions for use and maintenance.

- Wear appropriate personal protective equipment (PPE): When working with rigging equipment, always wear appropriate PPE, such as hard hats, safety glasses, and gloves.

- Be aware of your surroundings: Be aware of your surroundings and watch for any potential hazards.

- Never work alone: Never work alone when working with rigging equipment. Always have a qualified spotter or signaler present.

3. What are the different types of hitches and knots used in rigging?

There are a variety of hitches and knots used in rigging, each with a specific purpose and application. Some of the most common hitches and knots include:

- Bowline: The bowline knot is a strong and secure knot used to create a loop in a rope. It is often used to attach a rope to a post or other object.

- Clove hitch: The clove hitch knot is a simple and secure knot used to attach a rope to a post or other object. It is often used to secure a boat to a dock.

- Figure-eight knot: The figure-eight knot is a strong and secure knot used to join two ropes together. It is often used to create a loop in a rope or to tie a rope to a hook.

- Sheet bend knot: The sheet bend knot is a strong and secure knot used to attach a rope to a larger rope. It is often used to attach a sail to a mast.

- Square lashing: The square lashing knot is a strong and secure knot used to bind two objects together. It is often used to secure a load to a pallet or to bind two pieces of lumber together.

4. What are the different types of rigging signals?

There are a variety of rigging signals used to communicate with crane operators and other rigging personnel. Some of the most common rigging signals include:

- Hoist: The hoist signal is used to tell the crane operator to raise the load.

- Lower: The lower signal is used to tell the crane operator to lower the load.

- Swing: The swing signal is used to tell the crane operator to swing the load to the left or right.

- Stop: The stop signal is used to tell the crane operator to stop the load.

- Emergency stop: The emergency stop signal is used to tell the crane operator to stop the load immediately.

5. What are the different types of lifting devices?

There are a variety of lifting devices used in rigging, including cranes, hoists, and forklifts. Each type of lifting device has a specific purpose and application.

- Cranes: Cranes are used to lift and move heavy loads. They come in a variety of sizes and capacities.

- Hoists: Hoists are used to lift and move loads vertically. They come in a variety of sizes and capacities.

- Forklifts: Forklifts are used to lift and move loads horizontally. They come in a variety of sizes and capacities.

6. What are the factors to consider when selecting a lifting device?

When selecting a lifting device, it is important to consider the following factors:

- The weight of the load: The weight of the load will determine the size and capacity of the lifting device required.

- The height of the lift: The height of the lift will determine the length of the boom or lift required.

- The distance of the lift: The distance of the lift will determine the reach of the lifting device required.

- The type of environment: The type of environment in which the lifting device will be used will determine the features required, such as weather resistance or explosion-proof.

7. What is your experience with working at heights?

I have experience working at heights in a variety of settings, including on scaffolding, ladders, and roofs. I am comfortable working at heights and am familiar with the safety precautions that need to be taken.

8. What is your experience with working in confined spaces?

I have experience working in confined spaces, such as inside tanks and vessels. I am familiar with the safety precautions that need to be taken when working in confined spaces.

9. What is your experience with working with hazardous materials?

I have experience working with hazardous materials, such as chemicals and solvents. I am familiar with the safety precautions that need to be taken when working with hazardous materials.

10. What are your strengths and weaknesses as a Rigging Helper?

Strengths

- I am a hard worker and I am always willing to learn new things.

- I am a team player and I am always willing to help others.

- I am physically fit and I am able to work in a variety of conditions.

Weaknesses

- I am relatively new to the industry and I am still learning some of the ropes.

- I can sometimes be impatient and I need to work on my communication skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rigging Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rigging Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rigging Helper is responsible for assisting in the setup, maintenance, and dismantling of rigging systems used for various purposes such as construction, entertainment, and industrial settings. The primary responsibilities include:

1. Rigging Setup and Maintenance

Assist in the assembly, inspection, and maintenance of rigging equipment, including ropes, cables, winches, hoists, and other rigging hardware.

- Inspect equipment for damage or wear and ensure proper functionality.

- Follow rigging plans and specifications to ensure safe and efficient setup.

2. Material Handling

Loading, unloading, and transporting rigging materials and equipment to and from work sites.

- Operate forklifts or other material handling equipment to move heavy loads.

- Pack and unpack gear, including cables, slings, and rigging accessories.

3. Safety and Hazard Identification

Adhering to safety regulations and identifying potential hazards at work sites.

- Follow proper lifting techniques and work in a safe manner.

- Inspect work areas for hazards such as overhead obstacles or uneven surfaces.

4. Communication and Teamwork

Working effectively within a team environment and communicating with other crew members.

- Receive and carry out instructions from supervisors and lead riggers.

- Collaborate with other team members to ensure smooth rigging operations.

Interview Tips

To ace a Rigging Helper interview, it’s essential to prepare thoroughly while remaining confident and professional. Here are some tips to help you succeed:

1. Research the Company and Role

Take the time to learn about the company’s industry, projects, and company culture. This will demonstrate your interest and enthusiasm for the position.

- Research the company’s website, social media presence, and industry publications.

- Read the job description carefully and identify the key skills and experience they are looking for.

2. Prepare Your Rigging Experience

Highlight your relevant rigging experience, including any specific equipment or techniques you are proficient in. Quantify your accomplishments whenever possible.

- Provide examples of complex rigging setups you have assisted with.

- Quantify your experience by stating how many projects or installations you have been involved in.

3. Demonstrate Safety Knowledge

Emphasize your understanding of safety regulations and your commitment to working safely on rigging projects.

- Describe how you identify potential hazards in the workplace.

- Explain your experience in following safety protocols, such as using proper lifting techniques.

4. Practice Teamwork and Communication

Discuss your ability to work effectively within a team and communicate clearly with others. Provide examples of how you have contributed to team projects.

- Share experiences where you have successfully collaborated with others to complete rigging tasks.

- Describe your communication skills and how you ensure clear understanding within a team.

Next Step:

Now that you’re armed with the knowledge of Rigging Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rigging Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini