Are you gearing up for an interview for a Rigging Up Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rigging Up Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

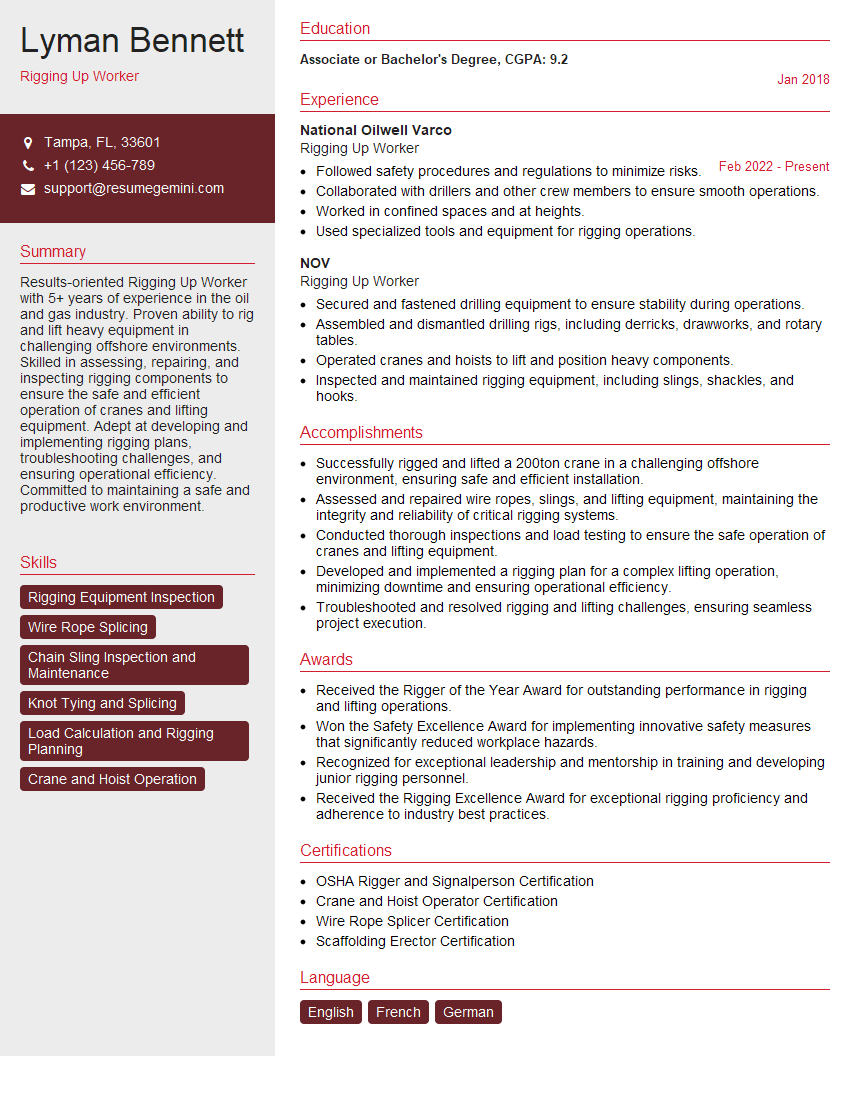

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rigging Up Worker

1. Explain the types of rigging equipment you are familiar with?

I am familiar with a wide range of rigging equipment, including:

- Hoists and cranes

- Slings and shackles

- Wire rope and chain

- Pulleys and blocks

- Anchor points and tie-downs

2. How do you determine the weight of a load before you rig it?

I use a variety of methods to determine the weight of a load before I rig it, including:

- Consulting the load chart for the equipment I am using

- Using a dynamometer

- Estimating the weight based on the size and density of the load

3. What are the different types of hitches and knots used in rigging?

The different types of hitches and knots used in rigging include:

- Bowline knot

- Clove hitch

- Figure-eight knot

- Square knot

- Trucker’s hitch

4. How do you inspect rigging equipment for damage?

I inspect rigging equipment for damage by looking for the following:

- Cracks or breaks in the metal

- Deformation or bending

- Corrosion or rust

- Worn or frayed ropes or slings

- Missing or damaged safety latches

5. What are the safety precautions that must be taken when rigging a load?

The safety precautions that must be taken when rigging a load include:

- Inspecting the rigging equipment for damage

- Determining the weight of the load

- Using the correct hitches and knots

- Ensuring that the load is properly balanced

- Keeping people and other objects clear of the load path

6. What are the different types of rigging systems?

The different types of rigging systems include:

- Single-leg rigging

- Multi-leg rigging

- Bridle rigging

- Basket rigging

- Span rigging

7. How do you calculate the load capacity of a rigging system?

I calculate the load capacity of a rigging system by considering the following factors:

- The strength of the individual components

- The configuration of the system

- The safety factor

8. What are the different types of lifting devices used in rigging?

The different types of lifting devices used in rigging include:

- Cranes

- Hoists

- Forklifts

- Manually operated lifting devices

9. How do you maintain rigging equipment?

I maintain rigging equipment by following these steps:

- Inspecting the equipment regularly

- Cleaning and lubricating the equipment

- Storing the equipment in a dry, protected place

- Following the manufacturer’s recommendations for maintenance

10. What are the common hazards associated with rigging?

The common hazards associated with rigging include:

- Falling objects

- Crushing injuries

- Electrical hazards

- Slips and falls

- Caught-in or between hazards

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rigging Up Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rigging Up Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rigging Up Worker is responsible for preparing and setting up equipment and materials for various operations in industries such as construction, mining, and entertainment. The core responsibilities include:1. Rigging and Dismantling Equipment

Assembling, dismantling, and inspecting various types of equipment and rigging systems.- Using hoists, cranes, and other lifting devices to move heavy machinery and materials.

- Inspecting rigging components for safety and adherence to standards.

2. Preparing and Setting Up Equipment

Preparing and setting up machinery, tools, and materials for specific operations.- Laying out equipment according to blueprints or specifications.

- Installing and connecting electrical, mechanical, and hydraulic systems.

3. Operating Equipment

Operating lifting equipment, machinery, and tools to perform various tasks.- Using cranes to lift and position heavy loads.

- Operating forklifts to move materials and equipment.

4. Maintaining Equipment

Performing basic maintenance and repairs on rigging equipment to ensure safety and functionality.- Lubricating and inspecting rigging components.

- Making minor adjustments and repairs.

Interview Tips

To ace the interview for a Rigging Up Worker position, candidates should:1. Research the Company and Industry

Learn about the company’s reputation, expertise, and projects. Familiarize yourself with the specific industry you will be working in.2. Highlight Relevant Skills and Experience

Emphasize experiences where you have successfully participated in rigging, equipment setup, and equipment operation. Quantify your accomplishments using specific numbers and metrics.3. Demonstrate Safety Awareness

Rigging work involves safety-critical tasks. Express your strong adherence to safety protocols and practices, such as PPE usage, load calculations, and risk assessment.4. Showcase Problem-Solving Abilities

Demonstrate your ability to identify and resolve problems that may arise during rigging operations. Provide examples of situations where you used logical thinking and practical solutions to overcome challenges.5. Prepare for Technical Questions

Be prepared to discuss technical aspects of rigging, such as load limits, rigging gear, and equipment specifications. Practice answering questions related to rigging methods and calculations.6. Be Physically Fit and Able

Rigging work requires physical stamina and strength. Highlight your ability to work in physically demanding conditions and lift heavy objects.7. Ask Intelligent Questions

Asking thoughtful questions during the interview demonstrates your interest and engagement. Inquire about safety protocols, training opportunities, and the company’s commitment to quality.8. Dress Professionally and Be Respectful

Present yourself in a professional and respectful manner, reflecting the safety-conscious and highly skilled nature of the role. Arrive on time and be courteous to the interviewers.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rigging Up Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!