Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rim Roller Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

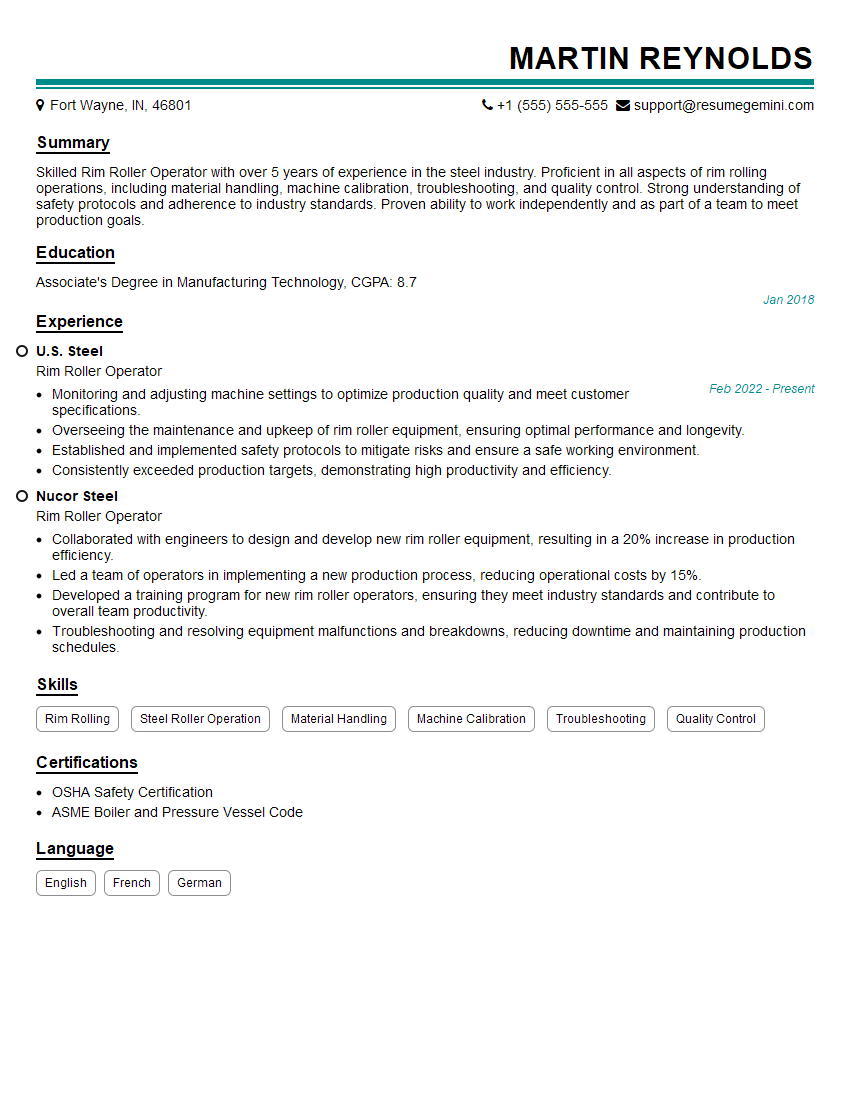

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rim Roller Operator

1. What are the key steps involved in operating a rim roller machine?

- Prepare the machine by checking and adjusting settings, such as roller gap and temperature.

- Load the rim onto the machine and secure it in place.

- Start the machine and feed the rim through the rollers, while monitoring the process.

- Unload the rolled rim and inspect it for quality.

- Clean and maintain the machine regularly to ensure optimal performance.

2. How do you ensure the accuracy and quality of the rolled rims?

Calibration and Maintenance

- Regularly calibrate the machine and its components to ensure precise measurements.

- Perform routine maintenance to keep the machine in optimal working condition.

Quality Control

- Inspect the rims before and after rolling to identify any defects or inconsistencies.

- Use measuring tools to verify that the rims meet the specified dimensions and tolerances.

- Monitor the temperature and roller pressure to ensure they are within the required range.

3. What are the common problems encountered when operating a rim roller machine, and how do you troubleshoot them?

- Roller defects: Identify worn or damaged rollers and replace them to maintain accuracy.

- Temperature issues: Adjust the temperature settings or check the heating elements for malfunctions.

- Uneven rolling: Inspect the roller alignment and adjust it if necessary.

- Rim defects: Check for imperfections in the rim material or surface, which may require re-rolling or discarding.

- Machine breakdowns: Follow established troubleshooting procedures, consult technical documentation, or contact the manufacturer for support.

4. What safety precautions should be taken when operating a rim roller machine?

- Wear appropriate safety gear, such as gloves, eye protection, and protective clothing.

- Operate the machine in a well-ventilated area to minimize exposure to fumes or dust.

- Keep the work area clean and organized to prevent tripping or falling hazards.

- Follow established safety protocols and lockout procedures when performing maintenance.

- Report any accidents or potential hazards immediately to the supervisor or safety personnel.

5. How do you maximize the efficiency of a rim roller machine?

- Regular maintenance: Keep the machine clean, lubricated, and calibrated to ensure optimal performance.

- Proper setup: Ensure that the machine is set up correctly, with the rollers aligned and the temperature settings optimized.

- Material handling: Load and unload rims efficiently to minimize downtime.

- Process optimization: Adjust feed rates and roller speeds to find the most efficient settings for the material being rolled.

- Monitoring and troubleshooting: Regularly monitor the machine’s performance and promptly address any issues to avoid unnecessary downtime.

6. What experience do you have in working with different types of rim materials?

- Mild steel: Explain your experience in rolling mild steel rims, including the specific techniques and settings used.

- Stainless steel: Discuss your knowledge of rolling stainless steel rims, highlighting the challenges and best practices involved.

- Aluminum: Describe your experience in rolling aluminum rims, emphasizing the importance of temperature control and roller pressure.

- Other materials: Mention any experience you have in rolling other types of rim materials, such as carbon fiber or composite materials.

7. How do you handle variations in rim thickness and diameter?

- Adjusting settings: Explain how you adjust the roller gap and other settings to accommodate different rim thicknesses and diameters.

- Roller selection: Discuss your approach to selecting the appropriate rollers for the specific rim dimensions.

- Test runs: Describe how you perform test runs to verify the accuracy of the settings and roller selection.

- Quality control: Explain how you ensure that the rolled rims meet the required specifications, regardless of variations in thickness or diameter.

8. What is your understanding of the industry standards and regulations related to rim rolling?

- Safety standards: Discuss your knowledge of safety regulations and standards related to rim rolling operations.

- Quality standards: Explain your understanding of the quality standards that apply to rolled rims, such as dimensional tolerances and surface finish requirements.

- Environmental regulations: Describe your awareness of any environmental regulations that may impact rim rolling operations, such as waste management and fume control.

9. How do you stay up-to-date with the latest advancements in rim rolling technology?

- Trade shows and conferences: Attend industry events to learn about new technologies and best practices.

- Technical publications: Read industry journals and articles to stay informed about advancements.

- Manufacturer updates: Stay in touch with rim roller manufacturers to get information on new developments and upgrades.

10. How would you handle a situation where you are asked to roll rims outside of the specified tolerances?

- Communication: Discuss with the supervisor or client to clarify the request and understand the reasons behind it.

- Assessment: Evaluate the feasibility of rolling within the requested tolerances and the potential risks involved.

- Collaboration: Consult with colleagues or engineers to seek advice and explore alternative approaches.

- Quality assurance: Explain the importance of maintaining quality standards and the potential consequences of deviating from them.

- Documentation: Document the decision-making process and any deviations from the specified tolerances, along with the reasons and approvals obtained.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rim Roller Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rim Roller Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rim Roller Operators play a crucial role in the automotive manufacturing industry. Their responsibilities encompass various tasks related to the production of wheel rims.

1. Machine Operation and Maintenance

Primary duty is operating the rim rolling machines effectively and efficiently.

- Monitor machine performance, troubleshoot any issues, and make necessary adjustments.

- Perform routine maintenance and cleaning of equipment to ensure optimal operation.

2. Quality Control

Maintain high quality standards in the production process.

- Inspect rims for defects, dimensions, and other specifications.

- Identify and correct any irregularities to meet quality requirements.

3. Material Handling

Handle raw materials and finished products efficiently.

- Load and unload materials from the machine using appropriate equipment.

- Move finished rims to designated storage areas for further processing.

4. Safety and Compliance

Adhere to safety regulations and company policies.

- Wear appropriate safety gear and follow established procedures to prevent accidents.

- Comply with environmental regulations and maintain a clean and organized workspace.

Interview Tips

Preparing thoroughly for a Rim Roller Operator interview can significantly increase your chances of success. Here are some essential tips to help you ace the interview.

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and the specific requirements of the Rim Roller Operator role. This will demonstrate your interest and enthusiasm for the position.

- Visit the company’s website and LinkedIn profile for information about their operations, products, and culture.

- Carefully review the job description and make note of key responsibilities and qualifications.

2. Practice Your Responses

Prepare answers to common interview questions related to your skills, experience, and motivations. Practicing your responses will boost your confidence and allow you to articulate your value effectively.

- Use the STAR method (Situation, Task, Action, Result) to highlight your past experiences and achievements.

- Quantify your accomplishments whenever possible using specific numbers and metrics.

3. Highlight Your Technical Skills

Emphasize your proficiency in operating rim rolling machines and performing quality control tasks. If you have any experience with specific equipment or software used in the industry, be sure to mention it.

- Discuss your understanding of rim manufacturing processes and quality standards.

- Share examples of how you have solved technical problems or improved machine efficiency.

4. Showcase Your Safety and Compliance Knowledge

Demonstrate your commitment to safety and compliance in the workplace. Explain how you prioritize safety in your work practices and maintain a clean and organized workspace.

- Describe your experience with adhering to safety protocols and regulations.

- Explain how you stay updated on industry best practices and standards.

5. Ask Meaningful Questions

At the end of the interview, take the opportunity to ask questions that show your interest in the company and the role. This indicates your engagement and desire to learn more about the organization.

- Ask about the company’s plans for growth and innovation.

- Inquire about opportunities for professional development and advancement within the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rim Roller Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rim Roller Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.