Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rim Turning Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

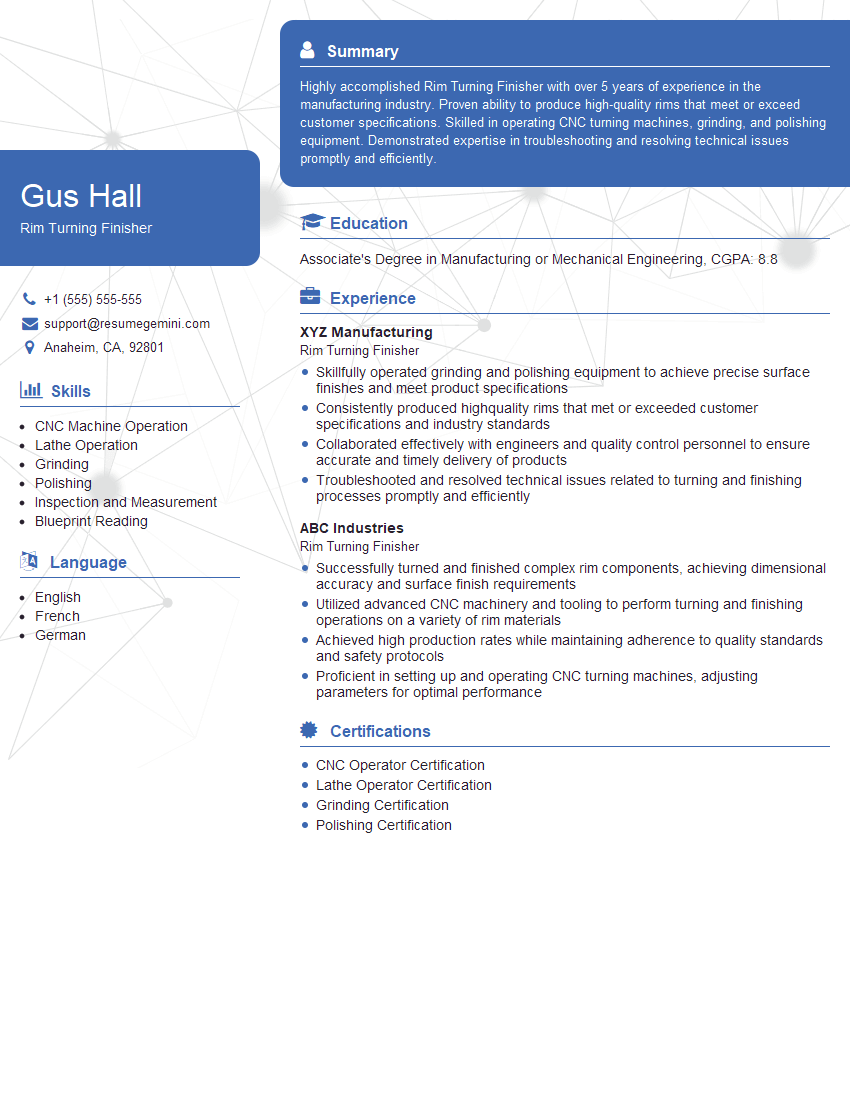

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rim Turning Finisher

1. Explain the process of rim turning and finishing?

Rim turning is a machining process used to finish the outer surface of a wheel rim. It involves removing excess material from the rim to achieve the desired shape and dimensions. Rim finishing is the final step in the process and involves polishing and buffing the rim to give it a smooth and shiny appearance.

- Rim turning is typically done using a lathe machine equipped with a cutting tool.

- The cutting tool is moved along the rim surface to remove material and create the desired shape.

- Rim finishing is done using a variety of tools and techniques, such as polishing wheels, buffing wheels, and compounds.

2. What are the different types of rim turning and finishing machines?

There are two main types of rim turning machines: manual and CNC (computer numerical control). Manual machines are operated by hand, while CNC machines are controlled by a computer program.

Types of rim finishing machines

- Polishing machines use rotating wheels with abrasive compounds to smooth and polish the rim surface.

- Buffing machines use rotating wheels with soft materials to create a high-gloss finish.

3. What are the important factors to consider when choosing a rim turning and finishing machine?

When choosing a rim turning and finishing machine, it is important to consider the following factors:

- The type of rims you will be working on

- The desired finish quality

- The production volume

- The budget

4. What are the common problems that can occur during rim turning and finishing?

Common problems that can occur during rim turning and finishing include:

- Chatter (vibration of the cutting tool)

- Tool wear

- Surface defects (such as scratches, nicks, or burrs)

- Dimensional inaccuracies

5. How do you troubleshoot and resolve problems that occur during rim turning and finishing?

To troubleshoot and resolve problems that occur during rim turning and finishing, it is important to:

- Identify the source of the problem

- Determine the cause of the problem

- Implement a solution to fix the problem

- Test the solution to ensure that it has resolved the problem

6. What are the safety precautions that should be taken when operating rim turning and finishing machines?

When operating rim turning and finishing machines, it is important to take the following safety precautions:

- Wear appropriate safety gear (such as safety glasses, gloves, and ear protection)

- Keep the work area clean and free of debris

- Be aware of the moving parts of the machine

- Never operate the machine if it is damaged or malfunctioning

7. What are the different types of cutting tools used in rim turning and finishing?

The different types of cutting tools used in rim turning and finishing include:

- Single-point cutting tools

- Multi-point cutting tools

- Abrasive cutting tools

8. What are the different types of surface finishes that can be achieved with rim turning and finishing?

The different types of surface finishes that can be achieved with rim turning and finishing include:

- Matte finish

- Satin finish

- Gloss finish

9. What are the quality control procedures that should be followed during rim turning and finishing?

The quality control procedures that should be followed during rim turning and finishing include:

- Inspecting the rims before and after machining

- Measuring the rims to ensure that they meet the desired dimensions

- Checking the surface finish of the rims

10. What are the latest trends in rim turning and finishing technology?

The latest trends in rim turning and finishing technology include:

- The use of CNC machines for greater precision and efficiency

- The development of new cutting tools and abrasives

- The use of automated systems for quality control

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rim Turning Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rim Turning Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rim Turning Finishers are responsible for the precision finishing of metal rims. They use specialized tools and equipment to create a smooth, accurate surface on the rims. Their key job responsibilities include:

1. Rim Preparation

Prepare rims for finishing by removing burrs, imperfections, and oxidation.

- Inspect rims for defects and damage.

- Use grinders, sanders, and other tools to remove burrs and imperfections.

- Apply chemical treatments to remove oxidation and prepare the surface for finishing.

2. Rim Turning

Use lathes and other specialized equipment to turn the rims to the desired size and shape.

- Set up and operate lathes and other equipment.

- Select and use appropriate cutting tools and abrasives.

- Monitor the turning process and make adjustments as needed.

- Measure and inspect turned rims to ensure accuracy and quality.

3. Rim Finishing

Polish and finish the turned rims to achieve the desired surface quality.

- Use grinders, buffers, and other tools to polish and finish the rims.

- Apply coatings or treatments to protect and enhance the surface finish.

- Inspect and package finished rims.

4. Quality Control

Ensure the quality of the finished rims by performing regular inspections and testing.

- Inspect finished rims for defects, imperfections, and dimensional accuracy.

- Perform testing to verify the strength, durability, and performance of the rims.

- Document and report quality control results.

Interview Tips

To ace the interview for a Rim Turning Finisher position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. Demonstrate your understanding of the role and how your skills align with the company’s needs.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Network with professionals in the field.

- Prepare specific examples of your experience and skills that are relevant to the job.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice delivering your answers clearly and concisely.

- Review common job responsibilities and prepare examples of how you have performed them.

- Practice answering questions about your technical skills and experience.

- Prepare questions to ask the interviewer that demonstrate your interest and enthusiasm.

3. Highlight Your Skills and Experience

Emphasize your technical skills, including your proficiency in using lathes, grinders, and other equipment. Highlight your experience in precision finishing and quality control.

- Use specific examples to demonstrate your skills and accomplishments.

- Quantify your results whenever possible, using numbers and metrics.

- Be prepared to discuss your knowledge of different materials and finishing techniques.

4. Show Your Passion and Enthusiasm

Express your passion for precision finishing and your commitment to delivering high-quality work. Show that you are enthusiastic about the opportunity to contribute to the company’s success.

- Share your reasons for pursuing a career as a Rim Turning Finisher.

- Discuss your goals and aspirations in the field.

- Ask insightful questions that demonstrate your interest and eagerness to learn.

Next Step:

Now that you’re armed with the knowledge of Rim Turning Finisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rim Turning Finisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini