Are you gearing up for a career in Ring Rolling Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ring Rolling Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

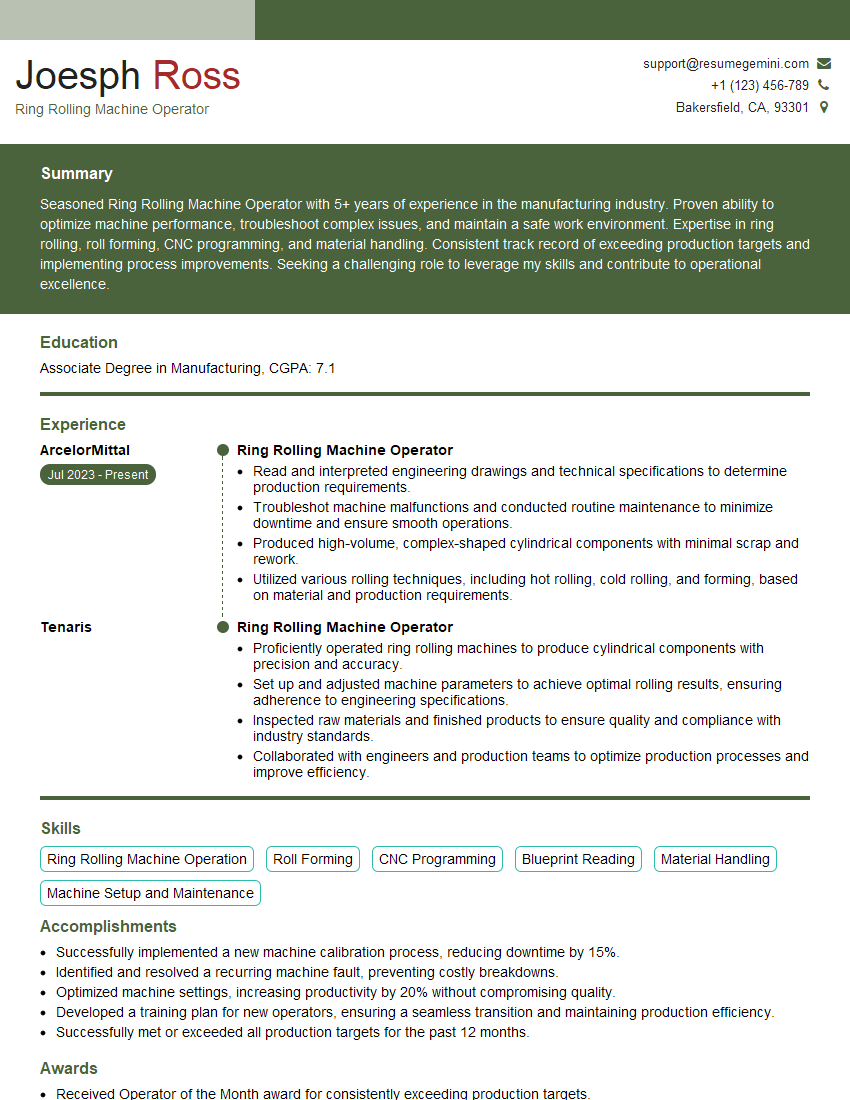

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ring Rolling Machine Operator

1. Describe the process of setting up a ring rolling machine.

The process of setting up a ring rolling machine involves the following steps:

- Selecting the correct tooling: This includes choosing the appropriate rolls, mandrels, and other accessories for the specific ring to be produced.

- Installing the tooling: The rolls and mandrels are mounted onto the machine, and the appropriate feed rate and spindle speed are selected.

- Loading the material: The material to be rolled is loaded into the machine, and the feed rate is adjusted to control the material flow.

- Starting the rolling process: The rolling process is initiated by engaging the rolls and mandrels. The material is gradually fed into the machine, and the rolls and mandrels rotate to form the ring.

2. How do you ensure the accuracy and consistency of the rings produced by the ring rolling machine?

Accuracy

- Proper tooling selection: Using the appropriate rolls and mandrels for the desired ring size and shape is crucial for accuracy.

- Precision machine setup: Ensure that the machine is correctly calibrated and aligned to minimize errors in the rolling process.

- Regular calibration: Calibrate the machine regularly to compensate for any wear or shifting of components that may affect accuracy.

Consistency

- Standardized process: Establish and adhere to a standardized operating procedure to ensure consistent setup and execution of the rolling process.

- Quality control: Implement a robust quality control system to inspect rings for dimensional accuracy and surface finish.

- Preventive maintenance: Regularly maintain and service the machine to minimize downtime and ensure consistent performance.

3. What are the different types of materials that can be rolled using a ring rolling machine?

Ring rolling machines can process a wide range of materials, including:

- Ferrous metals: Steel, stainless steel, iron

- Non-ferrous metals: Aluminum, copper, brass, titanium

- High-performance alloys: Inconel, Monel, Hastelloy

- Exotic materials: Zirconium, tantalum, niobium

4. How do you troubleshoot common problems that may arise during ring rolling?

- Material wrinkling: Adjust the feed rate or lubrication to reduce friction.

- Uneven wall thickness: Check the roll alignment and adjust the feed speed.

- Poor surface finish: Inspect the tooling for wear or damage, and adjust the lubrication.

- Ring distortion: Ensure that the material is properly annealed and heat-treated.

- Machine vibration: Check the balance of the tooling and inspect the machine for any loose components.

5. What are the safety precautions that must be observed when operating a ring rolling machine?

- Wear appropriate safety gear: This includes safety glasses, ear protection, and gloves.

- Securely fasten the material: Ensure that the material is securely held in place to prevent it from flying out during the rolling process.

- Maintain a clean work area: Keep the work area free of debris and tripping hazards.

- Never reach into the machine while it is in operation: Use a stick or other tool to retrieve any dropped objects.

- Follow lockout/tagout procedures: Always isolate the machine from power before performing any maintenance or repairs.

6. How do you maintain and calibrate a ring rolling machine?

Maintenance

- Regular lubrication: Lubricate all moving parts and components as specified in the manufacturer’s instructions.

- Tooling inspection and replacement: Regularly inspect rolls, mandrels, and other tooling for wear or damage. Replace them as needed.

- Machine cleaning: Remove any dirt, debris, or metal chips from the machine to prevent damage and ensure smooth operation.

Calibration

- Roll alignment: Use a dial indicator to ensure that the rolls are aligned properly.

- Mandrel alignment: Check the alignment of the mandrel to ensure that it is perpendicular to the rolls.

- Feed rate calibration: Adjust the feed rate according to the material being rolled and the desired ring size.

7. What are the different factors that affect the quality of the rings produced by a ring rolling machine?

- Material properties: The material’s strength, ductility, and hardness can affect the ring’s quality.

- Tooling selection: The appropriate rolls and mandrels must be used for the specific material and ring size.

- Machine setup: The machine must be properly calibrated and aligned to ensure accuracy and consistency.

- Rolling parameters: The feed rate, spindle speed, and lubrication must be optimized for the specific material and ring size.

- Operator skill: The operator’s experience and skill level can significantly impact the quality of the rings produced.

8. How do you handle scrap material generated during the ring rolling process?

Scrap material generated during the ring rolling process can be handled in various ways:

- Recycling: Scrap material can be recycled and used to produce new rings or other products.

- Landfilling: Scrap material can be disposed of in a landfill, but this method is becoming less environmentally acceptable.

- Incineration: Scrap material can be incinerated to generate energy or reduce its volume.

9. What are the emerging trends and advancements in ring rolling technology?

- Automated ring rolling: Automation and robotics are increasingly used to improve efficiency and reduce labor costs.

- Advanced tooling materials: New materials and coatings for rolls and mandrels are being developed to enhance durability and performance.

- Process optimization: Simulation and data analysis techniques are being used to optimize the ring rolling process and improve quality.

- Industry 4.0 integration: Ring rolling machines are becoming more connected and integrated with other systems in the manufacturing process.

10. How do you stay updated with the latest advancements in ring rolling technology?

- Industry trade shows: Attend industry trade shows and conferences to learn about new products and technologies.

- Technical publications: Read technical journals and publications dedicated to ring rolling and metal forming.

- Online resources: Utilize online resources, such as manufacturer websites and industry forums, to stay informed about the latest advancements.

- Networking: Connect with other ring rolling professionals and experts to exchange knowledge and ideas.

- Continuing education: Pursue continuing education opportunities, such as workshops and training programs, to enhance your skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ring Rolling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ring Rolling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ring Rolling Machine Operators are responsible for operating and maintaining ring rolling machines, which are used to form metal rings and other cylindrical components. These machines are used in a variety of industries, including aerospace, automotive, and manufacturing. Key job responsibilities include:

1. Operating Ring Rolling Machines

Ring Rolling Machine Operators are responsible for setting up, operating, and monitoring ring rolling machines. This involves loading material into the machine, setting machine parameters, and monitoring the progress of the rolling process. Operators must be able to identify and correct any errors that occur during the process.

2. Maintaining Ring Rolling Machines

Ring Rolling Machine Operators are also responsible for maintaining ring rolling machines. This involves performing regular maintenance tasks, such as cleaning, lubricating, and inspecting the machine. Operators must be able to identify and repair any problems that occur with the machine.

3. Quality Control

Ring Rolling Machine Operators are responsible for ensuring that the rings produced by the machine meet quality standards. This involves inspecting the rings for defects, such as cracks, voids, or dimensional errors. Operators must be able to use measuring tools and gauges to verify the dimensions of the rings.

4. Safety

Ring Rolling Machine Operators must follow all safety procedures when operating and maintaining ring rolling machines. This includes wearing appropriate safety gear, such as gloves, safety glasses, and earplugs. Operators must also be aware of the potential hazards associated with operating ring rolling machines, such as pinch points and moving machinery.

Interview Tips

To ace an interview for a Ring Rolling Machine Operator position, it is important to prepare thoroughly. Here are a few tips to help you succeed:

1. Research the Company and the Position

Before your interview, take the time to learn about the company and the position you are applying for. This will help you answer questions intelligently and show the interviewer that you are genuinely interested in the job.

2. Practice Your Answers

Once you have a good understanding of the company and the position, take some time to practice your answers to common interview questions. This will help you feel more confident and articulate during the interview.

3. Be Enthusiastic and Professional

During the interview, it is important to be enthusiastic and professional. This will make a good impression on the interviewer and show them that you are passionate about the job.

4. Ask Questions

Don’t be afraid to ask questions during the interview. This shows the interviewer that you are engaged and interested in the job. It also gives you an opportunity to learn more about the company and the position.

5. Follow Up

After the interview, be sure to follow up with the interviewer. This could involve sending a thank-you note or email. This is a good way to show your continued interest in the job and to remind the interviewer of your qualifications.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ring Rolling Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.