Feeling lost in a sea of interview questions? Landed that dream interview for Riprap Placing Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Riprap Placing Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

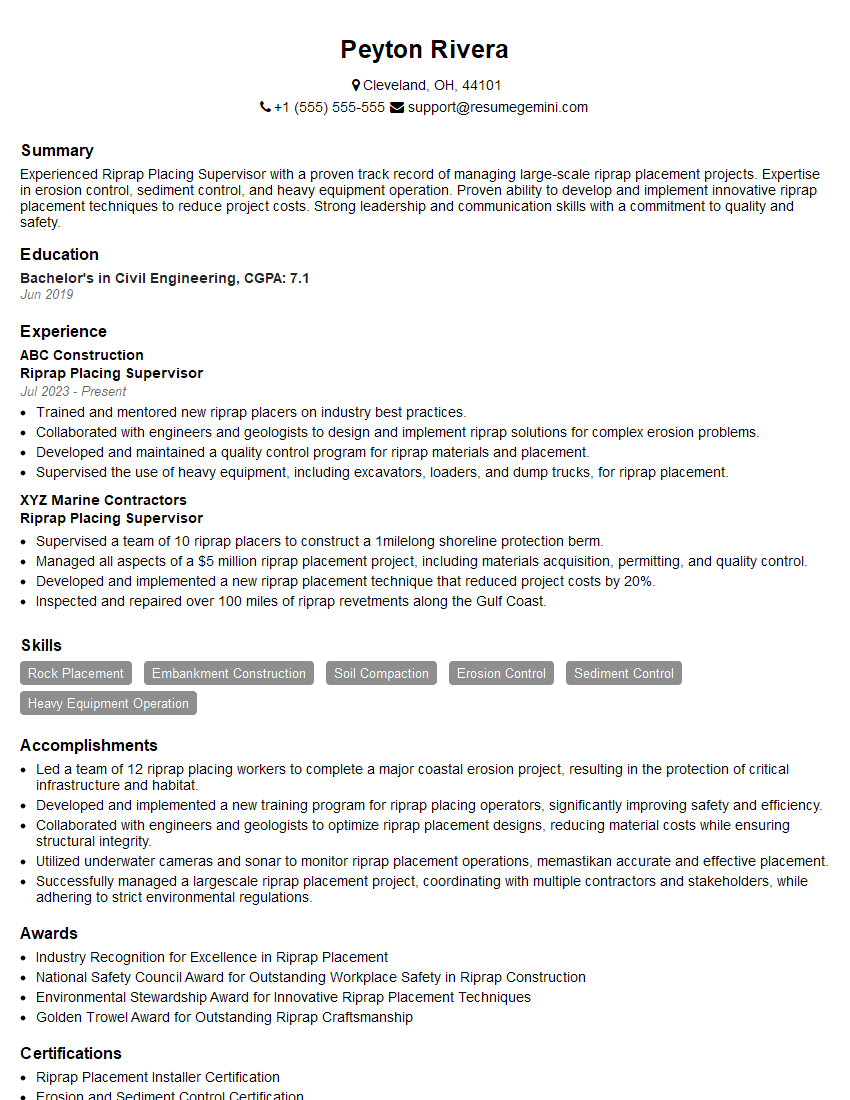

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Riprap Placing Supervisor

1. How would you determine the appropriate size and gradation of riprap to be placed based on the design criteria?

- Refer to the project design criteria and specifications.

- Consider the size and energy of the waves or currents that the riprap will be subjected to.

- Calculate the potential tractive force acting on the riprap based on the design conditions.

- Review and apply industry standards and guidelines for riprap sizing and gradation.

- Consult with geotechnical engineers and other experts as necessary for specific project requirements.

2. What factors would you consider when selecting a placement method for riprap?

Equipment availability

- Consider the available equipment, such as cranes, excavators, and dump trucks, and their capabilities.

- Assess the accessibility of the placement site and the potential reach of the equipment.

Water conditions

- Take into account the water depth, currents, and wave action at the placement site.

- Determine if special measures, such as barges or divers, are required for underwater placement.

Environmental considerations

- Consider the potential impact on sensitive habitats, endangered species, and water quality.

- Comply with applicable environmental regulations and guidelines.

3. What are the key quality control measures you would implement to ensure the proper placement and compaction of riprap?

- Establish clear specifications and procedures for riprap placement and compaction.

- Inspect the riprap materials prior to placement to verify their size, gradation, and quality.

- Monitor the placement process to ensure it is carried out as per the design and specifications.

- Use appropriate compaction equipment and techniques to achieve the required density and stability.

- Conduct post-placement inspections and testing to verify the adequacy of the riprap layer.

4. How would you manage a team of workers on a riprap placement project?

- Provide clear instructions and training to the workers on the project goals, safety protocols, and placement techniques.

- Assign specific roles and responsibilities to each worker based on their skills and experience.

- Monitor the progress of the work and provide feedback and guidance to the workers.

- Address any challenges or issues that arise during the placement process promptly and effectively.

- Maintain a positive and collaborative work environment to promote productivity and safety.

5. What safety precautions would you take when working on a riprap placement project?

- Wear appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and gloves.

- Establish and maintain safe work zones around equipment and materials.

- Be aware of potential hazards, such as falling rocks, slippery surfaces, and moving equipment.

- Follow established safety protocols for handling and placing riprap materials.

- Conduct regular safety inspections and training to ensure that all workers are aware of and comply with safety regulations.

6. What environmental regulations and guidelines would you be familiar with when working on a riprap placement project?

- Clean Water Act

- Endangered Species Act

- Migratory Bird Treaty Act

- National Environmental Policy Act (NEPA)

- Coastal Zone Management Act

- Local and state environmental regulations

7. What is the difference between a riprap revetment and a riprap seawall?

- A riprap revetment is a protective layer of riprap placed on a slope to prevent erosion from waves or currents.

- A riprap seawall is a vertical or near-vertical wall constructed of riprap to protect a shoreline or structure from wave action.

- Revetments are typically used in areas with milder wave action, while seawalls are used in areas with more severe wave energy.

8. What is the purpose of a geotextile layer in a riprap placement project?

- To prevent the migration of fines from the underlying soil into the riprap layer.

- To improve drainage and prevent waterlogging.

- To provide additional stability to the riprap layer.

- To reduce the risk of scour and erosion beneath the riprap.

9. What are the advantages and disadvantages of using recycled concrete as riprap material?

Advantages

- Cost-effective and environmentally friendly.

- Durable and can withstand harsh conditions.

- Can be used in a variety of applications, including revetments, seawalls, and breakwaters.

Disadvantages

- Can be difficult to handle and place.

- May require additional processing to meet size and gradation requirements.

- Not as aesthetically pleasing as natural stone riprap.

10. What are the key factors that can affect the long-term performance of a riprap structure?

- Proper design and construction.

- Wave and current forces.

- Material quality and gradation.

- Environmental factors, such as freeze-thaw cycles and salt spray.

- Maintenance and repairs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Riprap Placing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Riprap Placing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Riprap Placing Supervisor plays a crucial role in ensuring the successful placement of riprap, a protective layer of rocks used to reinforce shorelines, slopes, and other structures. Key responsibilities include:Coordinating and supervising the placement of riprap using heavy equipment such as cranes and excavators.

1. Ensuring Quality Control

Ensuring the quality and accuracy of riprap placement according to design specifications and industry standards.

2. Communicating with stakeholders

Collaborating with engineers, contractors, and clients to ensure alignment and address any concerns or issues.

3. Managing Safety

Enforcing safety protocols, inspecting equipment, and conducting regular safety briefings to minimize risks.

4. Monitoring Progress

Tracking progress and identifying any potential delays or challenges, and implementing corrective measures as necessary.

Interview Tips

To ace an interview for a Riprap Placing Supervisor position, candidates should follow these preparation tips:Research the company and the specific project you’re applying for, demonstrating your understanding of their goals and requirements.

1. Highlight Your Experience

Emphasize your relevant experience and qualifications, including any certifications or specialized training in riprap placement.

2. Showcase Your Knowledge

Demonstrate your technical knowledge of riprap materials, placement techniques, and industry best practices.

3. Prepare Example Outline

Prepare examples that illustrate your ability to coordinate projects, manage teams, and resolve challenges effectively, following an Example Outline:

- Situation: Describe a specific situation or challenge you faced.

- Task: Explain the task you were responsible for.

- Action: Outline the specific actions you took to address the situation.

- Result: Quantify the positive outcomes or impact of your actions.

4. Practice Your Communication Skills

Practice your communication and interpersonal skills, as you’ll need to effectively collaborate with a diverse team and stakeholders.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Riprap Placing Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!