Are you gearing up for an interview for a Rivet Bucker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rivet Bucker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

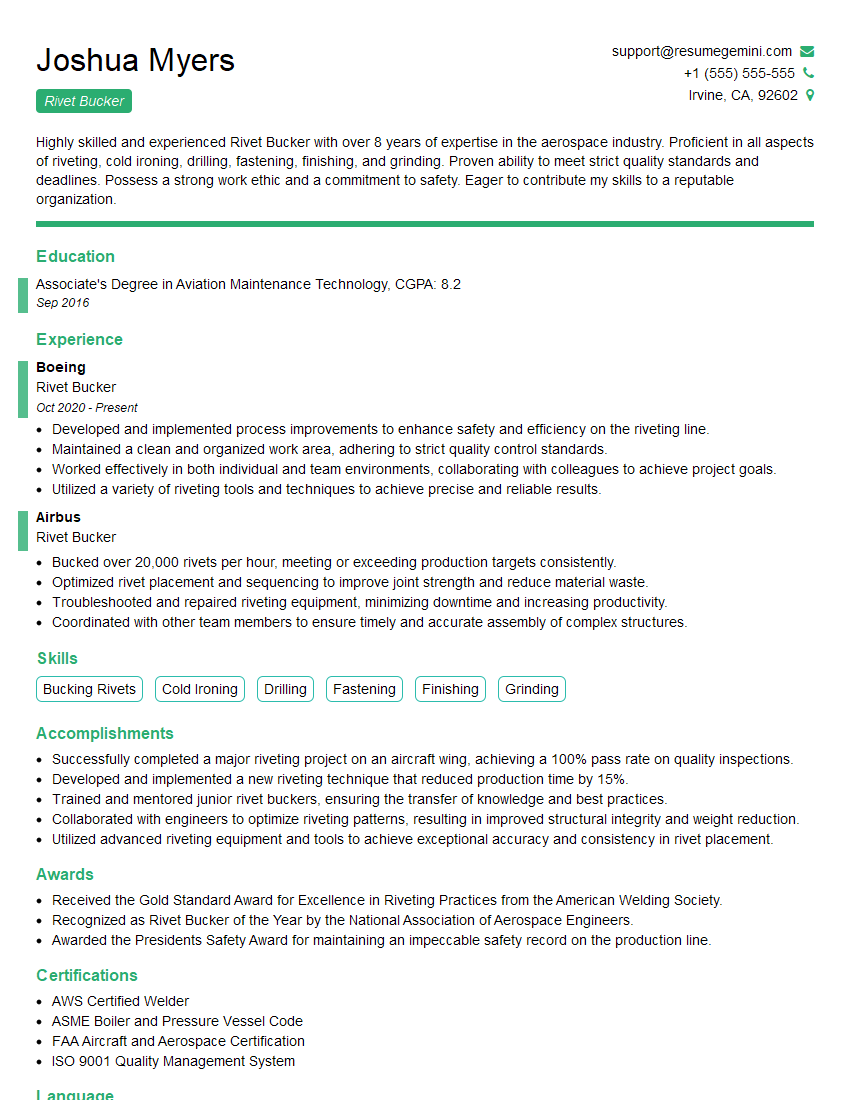

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rivet Bucker

1. What are the different types of rivets used in construction?

- Solid rivets

- Tubular rivets

- Semi-tubular rivets

- Explosive rivets

2. What are the advantages and disadvantages of using rivets in construction?

Advantages

- Strong and durable

- Easy to install

- Can be used in a variety of applications

Disadvantages

- Can be difficult to remove

- Can create noise and vibration during installation

3. What are the different types of rivet guns?

- Manual rivet guns

- Pneumatic rivet guns

- Hydraulic rivet guns

4. What are the safety precautions that should be taken when using a rivet gun?

- Wear safety glasses

- Wear earplugs

- Keep the rivet gun pointed away from yourself and others

- Do not use the rivet gun if it is damaged

5. What are the different types of rivet setting dies?

- Universal dies

- Flat dies

- Cup dies

- Tapered dies

6. How do you choose the right rivet setting die for the job?

- Consider the type of rivet being used

- Consider the material of the workpiece

- Consider the thickness of the workpiece

7. What are the different types of rivets that can be used in aircraft construction?

- Solid rivets

- Tubular rivets

- Semi-tubular rivets

- Blind rivets

8. What are the different types of rivet inspection methods?

- Visual inspection

- Magnetic particle inspection

- Penetrant testing

- Ultrasonic testing

9. What are the different standards that apply to rivet construction?

- ASTM International

- American National Standards Institute

- Society of Automotive Engineers

10. What are the different types of equipment that are used for riveting?

- Rivet guns

- Riveting hammers

- Squeezers

- Hydraulic presses

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rivet Bucker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rivet Bucker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rivet Bucker plays a crucial role in the fabrication process, ensuring the secure fastening of rivets. Here are the key responsibilities associated with this position:

1. Rivet Driving and Installation

The primary responsibility of a Rivet Bucker is to drive and install rivets efficiently. This involves aligning rivets precisely, securing them in place, and applying the necessary force to form a strong joint.

- Accurately positioning and aligning rivets for optimal fastening.

- Applying the appropriate force and pressure to drive rivets securely.

2. Preparing Surfaces

Before installing rivets, Rivet Buckers prepare the mating surfaces to ensure proper adhesion. This includes tasks such as cleaning surfaces, removing debris, and applying primers or adhesives.

- Cleaning and preparing surfaces to enhance rivet adhesion.

- Applying primer or adhesive to improve the bonding strength of rivets.

3. Equipment Maintenance

Rivet Buckers are responsible for maintaining their tools and equipment in optimal condition. This includes tasks such as cleaning, lubricating, and adjusting tools, replacing worn parts, and performing basic troubleshooting.

- Cleaning and maintaining riveting tools to ensure proper operation.

- Checking and replacing worn or damaged parts to prevent breakdowns.

4. Quality Control

Rivet Buckers are actively involved in quality control measures to ensure the integrity of riveted joints. This includes inspecting rivets for proper installation, ensuring the specified number of rivets are used, and conducting visual inspections to identify potential defects.

- Inspecting riveted joints to ensure they meet quality standards.

- Verifying the correct number of rivets have been installed.

Interview Preparation Tips

To ace the interview for a Rivet Bucker position, candidates should focus on highlighting their skills, experience, and knowledge related to the key job responsibilities. Here are some interview preparation tips to help:

1. Research the Company

Thoroughly research the company’s background, products or services, recent news, and values before the interview. This demonstrates your genuine interest in the position and the company’s culture.

- Visit the company’s website, social media pages, and industry-related publications.

- Identify the company’s core products or services and their market position.

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and qualifications. Practice answering these questions aloud to improve your delivery and confidence.

- Tell me about yourself and your experience in riveting.

- Describe your understanding of the riveting process.

- How do you ensure the quality of your work?

3. Highlight Your Skills and Experience

During the interview, emphasize your key skills and experience that are relevant to the Rivet Bucker role. Provide specific examples of your work to demonstrate your abilities.

- Showcase your proficiency in using various riveting tools and equipment.

- Provide examples of successful riveting projects you have completed.

4. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer at the end of the interview. This shows your interest in the position and the company.

- Ask about the specific projects you would be working on.

- Inquire about the company’s growth plans and industry trends.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rivet Bucker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rivet Bucker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.