Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rivet Flunky interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rivet Flunky so you can tailor your answers to impress potential employers.

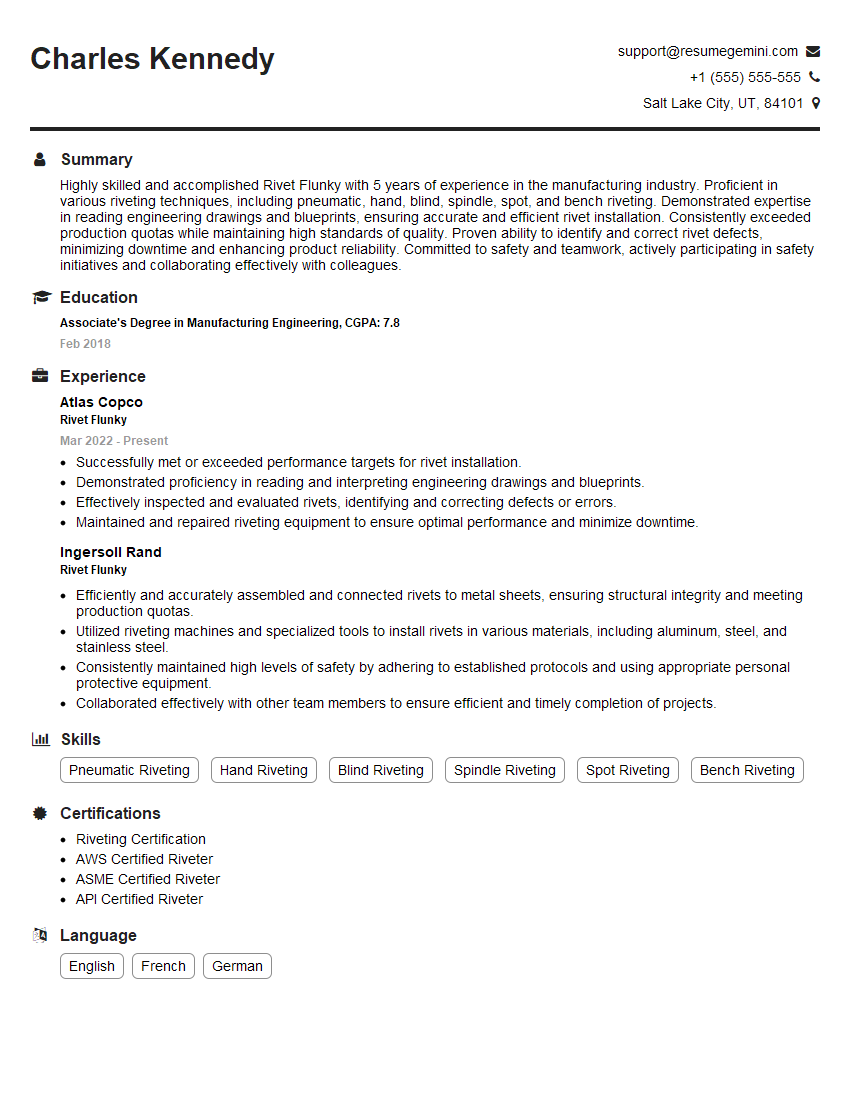

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rivet Flunky

1. What are the key responsibilities of a Rivet Flunky?

As a Rivet Flunky, my primary responsibilities would encompass:

- Inspecting and verifying rivets for dimensional accuracy, surface finish, and any defects

- Ensuring proper installation of rivets using appropriate tools and techniques

- Performing routine maintenance and calibration of riveting equipment

- Adhering to all safety protocols and industry standards

- Maintaining a clean and organized work area

2. What are the different types of riveting tools you have used, and what are their key features?

Pneumatic Riveting Tools

- Operate on compressed air, providing high power and speed

- Used for heavy-duty applications and high-volume production

Hydraulic Riveting Tools

- Use hydraulic pressure to create force, providing precise and controlled riveting

- Suitable for delicate or high-strength materials

Manual Riveting Tools

- Hand-operated, requiring physical force to set rivets

- Used for small-scale or low-volume applications

3. How do you determine the correct rivet size and type for a specific application?

I consider multiple factors when determining the right rivet size and type:

- Material thickness and hardness

- Joint strength requirements

- Environmental conditions (e.g., temperature, humidity)

- Load type (e.g., static, dynamic)

- Riveting tool capabilities

- Industry standards and specifications

4. What are the common defects that can occur during riveting, and how do you inspect for them?

Common riveting defects include:

- Loose rivets: Inspect by testing for movement or vibration

- Overdriven rivets: Look for deformed rivet heads or damage to the surrounding material

- Underdriven rivets: Examine for gaps between the rivet head and the material

- Misaligned rivets: Check for rivets that are not perpendicular to the joint

- Cracked rivets: Inspect for surface cracks or breaks

5. What are the safety precautions that must be taken when performing riveting operations?

Ensuring safety in riveting operations involves adhering to the following precautions:

- Wearing appropriate PPE (e.g., safety glasses, gloves, hearing protection)

- Inspecting tools and equipment before use

- Securing workpieces properly

- Avoiding loose clothing or jewelry

- Being aware of surroundings and potential hazards

- Following manufacturer’s instructions and industry standards

6. How do you maintain and calibrate riveting equipment?

Maintaining and calibrating riveting equipment is essential for optimal performance and safety:

- Regular Cleaning: Remove debris and grease from tools and accessories

- Lubrication: Apply lubricants to moving parts as per manufacturer’s guidelines

- Calibration: Use precision gauges and reference materials to ensure accuracy

- Testing: Conduct test rivets to verify proper functioning

- Record Keeping: Maintain records of maintenance and calibration activities

7. How do you handle situations where the specified riveting parameters seem inadequate for the application?

When encountering such situations, I take the following steps:

- Re-evaluate Requirements: Confirm the specifications with the design team or supervisor

- Assess Material Properties: Determine the strength and thickness of the materials involved

- Consider Load Conditions: Analyze the type and magnitude of loads the joint will experience

- Explore Alternative Riveting Methods: Research and consult with experts to find alternative solutions

- Propose Adjustments: Suggest modifications to the riveting parameters or design, providing technical justification

8. What techniques do you use to ensure the quality of riveted joints?

To ensure the quality of riveted joints, I employ the following techniques:

- Visual Inspection: Examine joints for proper alignment, flush rivets, and absence of defects

- Destructive Testing: Conduct tests (e.g., shear tests) to verify joint strength

- Non-Destructive Testing (NDT): Use methods like ultrasonic testing to detect internal flaws or voids

- Process Control: Implement measures to maintain consistent riveting parameters (e.g., force, time)

- Continuous Improvement: Analyze results and identify areas for improvement in riveting processes

9. How do you prioritize multiple tasks and manage your time effectively as a Rivet Flunky?

To effectively manage my time and prioritize tasks, I follow these strategies:

- Set Priorities: Determine the most important and urgent tasks based on deadlines and impact

- Create a Schedule: Plan my day to allocate time for each task efficiently

- Break Down Large Tasks: Divide complex tasks into smaller, manageable chunks

- Delegate Responsibilities: Seek assistance from colleagues or team members when appropriate

- Use Time Management Tools: Leverage tools like calendars, task lists, and reminders to stay organized

10. How do you stay updated with the latest industry trends and best practices in riveting?

To remain current with industry trends and best practices, I engage in the following activities:

- Attend Industry Events: Participate in conferences, workshops, and seminars

- Read Technical Publications: Subscribe to industry magazines and journals

- Network with Professionals: Connect with fellow Rivet Flunkies and industry experts

- Conduct Research: Explore new technologies, materials, and techniques through online resources

- Seek Training Opportunities: Enroll in courses or workshops to enhance my skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rivet Flunky.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rivet Flunky‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rivet Flunky is responsible for assisting in the assembly and repair of aircraft and other structures by hammering, drilling, and riveting metal parts together. They may also perform other tasks as assigned, such as cleaning, organizing, and stocking supplies.

1. Assist in the assembly and repair of aircraft and other structures

This may involve hammering, drilling, and riveting metal parts together. The Rivet Flunky must be able to follow instructions carefully and work accurately to ensure that the aircraft or structure is assembled or repaired correctly.

2. Clean, organize, and stock supplies

The Rivet Flunky is responsible for keeping the work area clean and organized. This may involve sweeping, mopping, and putting away tools and materials. They must also keep track of inventory and order supplies as needed.

3. Other duties as assigned

The Rivet Flunky may also be asked to perform other tasks, such as assisting with inspections, painting, and welding. They must be willing to learn new skills and be able to work independently.

Interview Tips

To ace an interview for a Rivet Flunky position, it is important to be prepared and to highlight your skills and experience. Here are a few tips to help you prepare for the interview:

1. Research the company and the position

This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can research the company’s website, social media pages, and Glassdoor reviews. You can also reach out to the hiring manager or recruiter to ask questions about the position.

2. Practice your answers to common interview questions

Some common interview questions that you may be asked include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- How do you handle stress?

- What are your salary expectations?

It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills in relation to the position. Be sure to highlight your experience in hammering, drilling, and riveting metal parts together. You should also mention any other relevant skills, such as cleaning, organizing, and stocking supplies.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic about the position and who has a positive attitude. Be sure to smile and make eye contact with the interviewer. You should also be prepared to talk about your passion for the aviation industry.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rivet Flunky role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.