Are you gearing up for a career in Rivet Hole Puncher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rivet Hole Puncher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

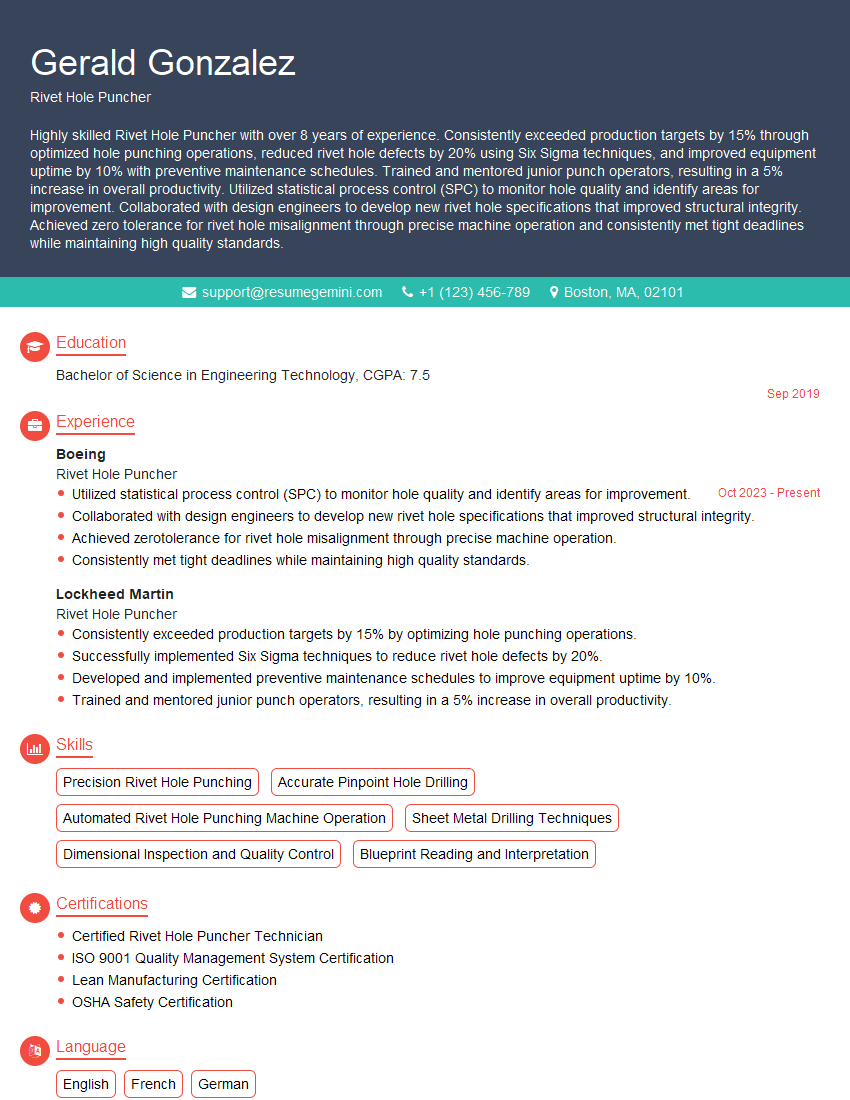

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rivet Hole Puncher

1. Tell me about your experience in operating a rivet hole puncher?

I have been operating a rivet hole puncher for the past 5 years. I am familiar with all aspects of the machine, including setup, operation, and maintenance. I have a strong understanding of the safety protocols that must be followed when operating the machine, and I am always careful to follow them. I am also proficient in using a variety of hole punches, and I can accurately punch holes in a variety of materials, including metal, plastic, and wood.

2. What are the different types of rivet hole punches?

Manual rivet hole punches

- These are the most basic type of rivet hole punch, which can be simply operated by hand.

- They are typically used for small projects or for punching holes in thin materials.

Electric rivet hole punches

- These are more powerful than manual rivet hole punches, and they can be used to punch holes in thicker materials.

- They are also typically faster than manual rivet hole punches.

Hydraulic rivet hole punches

- These are the most powerful type of rivet hole punch, and they can be used to punch holes in very thick materials.

- They are also typically the most expensive type of rivet hole punch.

3. What are the factors to consider when choosing a rivet hole punch?

There are several factors to consider when choosing a rivet hole punch, including:

- The type of material you will be punching holes in

- The thickness of the material

- The size of the holes you need to punch

- The speed at which you need to punch the holes

- The budget you have available

4. What are the safety precautions that must be taken when operating a rivet hole punch?

There are several safety precautions that must be taken when operating a rivet hole punch, including:

- Always wear safety glasses and gloves when operating the machine.

- Never place your hands or fingers near the punching area.

- Always secure the material you are punching in place before starting the machine.

- Never operate the machine if it is damaged or malfunctioning.

- Always follow the manufacturer’s instructions for operating the machine.

5. How do you maintain a rivet hole punch?

To maintain a rivet hole punch, you should:

- Clean the machine regularly with a damp cloth.

- Oil the moving parts of the machine regularly.

- Inspect the machine for damage regularly and make repairs as needed.

- Have the machine serviced by a qualified technician on a regular basis.

6. What are the common problems that can occur with a rivet hole punch?

Some common problems that can occur with a rivet hole punch include:

- The punch may become dull and need to be replaced.

- The die may become damaged and need to be replaced.

- The machine may not be properly lubricated.

- The machine may be overloaded.

- The machine may be malfunctioning.

7. How do you troubleshoot a rivet hole punch?

To troubleshoot a rivet hole punch, you should:

- Check the punch and die for damage or wear.

- Check the machine for proper lubrication.

- Check the machine for overloading.

- Check the machine for malfunctions.

8. What are the different types of rivets?

There are many different types of rivets, including:

- Solid rivets

- Tubular rivets

- Blind rivets

- Self-piercing rivets

- Explosive rivets

9. What are the different materials that rivets can be made of?

Rivets can be made of a variety of materials, including:

- Steel

- Aluminum

- Copper

- Brass

- Stainless steel

10. What are the different applications for rivets?

Rivets are used in a wide variety of applications, including:

- Construction

- Manufacturing

- Automotive

- Aerospace

- Medical

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rivet Hole Puncher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rivet Hole Puncher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rivet Hole Puncher is primarily responsible for operating a rivet hole punching machine to create holes in metal sheets for the insertion of rivets. The job requires precision and attention to detail to ensure that the holes are punched accurately and efficiently. Other key responsibilities include:

1. Machine Operation

Set up and operate rivet hole punching machines according to specifications.

- Load and unload metal sheets.

- Adjust machine settings for different hole sizes and materials.

2. Hole Punching

Punch holes in metal sheets using a variety of tools and techniques.

- Check hole dimensions and alignment to ensure accuracy.

- Inspect punched sheets for defects and rework as necessary.

3. Quality Control

Maintain high quality standards for punched holes.

- Monitor hole size, location, and spacing.

- Identify and correct errors promptly.

4. Safety Compliance

Follow established safety procedures and wear appropriate protective gear.

- Operate machines safely and responsibly.

- Maintain a clean and organized work area.

Interview Tips

To ace an interview for a Rivet Hole Puncher position, it’s crucial to prepare thoroughly and showcase your skills and qualifications. Here are some tips to help you succeed:

1. Research the Company and Position

Gather information about the company’s products, services, and culture. This knowledge will help you understand the company’s needs and tailor your answers accordingly. Thoroughly review the job description to identify the essential skills and qualifications required.

- Visit the company’s website.

- Read industry publications and news articles.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating rivet hole punching machines and your ability to produce accurate and consistent results. Quantify your accomplishments whenever possible to demonstrate your impact on the previous organization. Highlight your attention to detail, quality control measures, and safety compliance practices.

- Provide specific examples of successful hole punching projects.

- Discuss your understanding of different hole types and materials.

3. Demonstrate Safety Consciousness

Interviewers will be keen to assess your understanding of safety protocols. Emphasize your commitment to working safely and your knowledge of industry regulations. Discuss your experience in following established safety procedures and wearing appropriate protective gear.

- Share examples of how you have identified and mitigated potential hazards.

- Explain how you maintain a clean and organized work area.

4. Prepare for Technical Questions

Expect to be asked technical questions about rivet hole punching machines and processes. Be prepared to discuss your knowledge of machine setup, hole size and spacing calculations, and quality control procedures. Demonstrate your understanding of different hole types, materials, and potential challenges.

- Practice answering common technical questions.

- Review the principles of rivet hole punching.

5. Ask Thoughtful Questions

Asking insightful questions during the interview shows that you are engaged and interested in the position. Prepare thoughtful questions that demonstrate your understanding of the industry and the company’s business. This also provides an opportunity to clarify any details about the role or the company.

- Ask about the company’s growth plans and future projects.

- Inquire about opportunities for professional development and training.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rivet Hole Puncher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.