Are you gearing up for a career in Rivet Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rivet Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

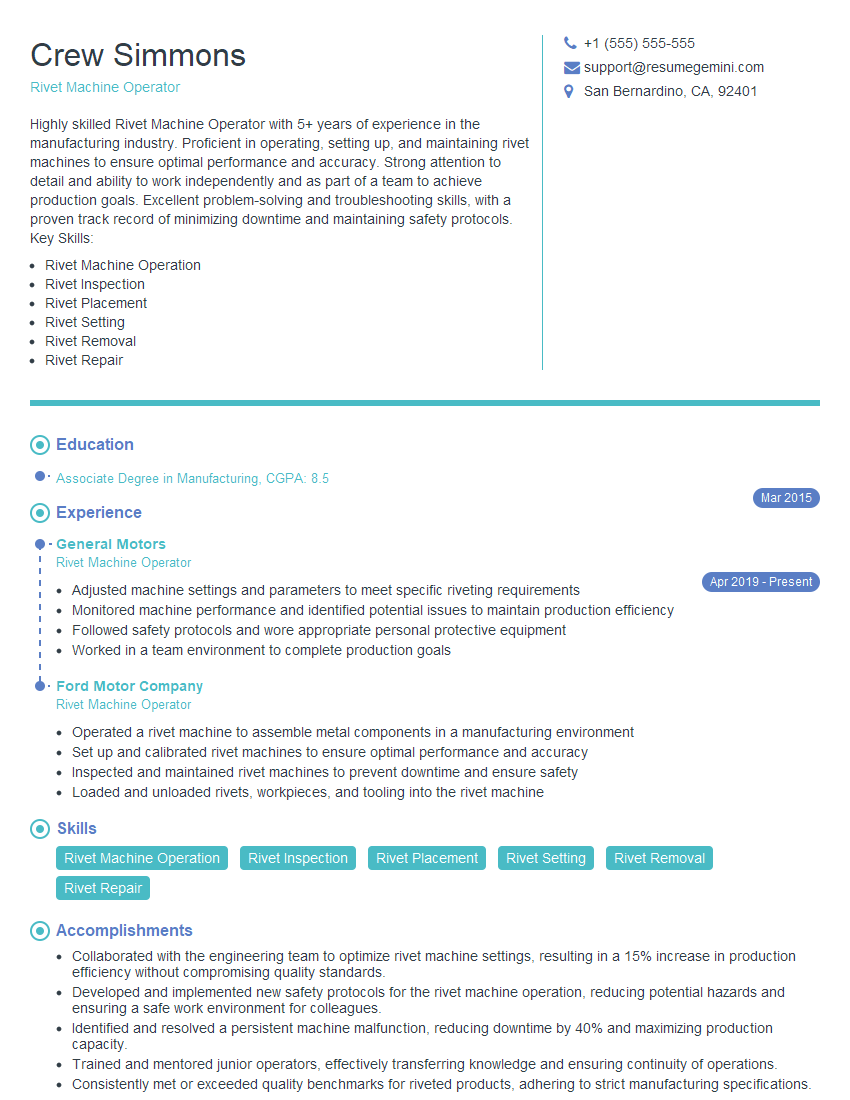

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rivet Machine Operator

1. What are the different types of rivets used in manufacturing?

There are various types of rivets used in manufacturing, including:

- Solid rivets: Made of a single piece of metal, providing a strong and permanent joint.

- Tubular rivets: Hollow rivets that are deformed during installation, creating a strong expansion fit.

- Blind rivets: Designed for use when access is limited to one side of the joint, typically installed with a rivet gun.

- Self-piercing rivets: Can be installed without pre-drilling holes, piercing through the materials being joined.

- Explosive rivets: Installed using an explosive charge, creating a strong and vibration-resistant joint.

2. Describe the process of setting a rivet using a rivet machine.

Feeding the rivet

- Place the rivet in the feed hopper or tube of the rivet machine.

Positioning the rivet

- Align the rivet with the holes in the materials to be joined.

Setting the rivet

- Activate the rivet machine to drive the rivet through the holes.

- The rivet is formed and expanded, creating a secure joint.

Finishing the process

- Remove the completed rivet from the machine.

3. What are the key factors that affect the strength of a riveted joint?

The strength of a riveted joint is influenced by several factors, including:

- Riveting material: The material used for the rivets, such as steel, aluminum, or stainless steel, affects their strength.

- Rivet type: Solid, tubular, blind, or self-piercing rivets have different strength characteristics.

- Rivet size: The diameter and length of the rivets determine their load-bearing capacity.

- Joint design: The number and spacing of rivets, as well as the overlap of the materials, influence the joint strength.

- Installation process: Proper setting techniques and equipment ensure a secure and strong riveted joint.

4. How do you troubleshoot common problems encountered when operating a rivet machine?

- Rivets not setting properly: Check the machine’s alignment, rivet size, and material compatibility.

- Leakage around rivets: Inspect the rivet holes for damage or misalignment, and ensure proper rivet setting.

- Machine malfunction: Identify the specific issue (e.g., electrical, mechanical), refer to the manufacturer’s manual, and contact technical support if necessary.

- Excessive noise or vibration: Check the machine for loose parts, proper lubrication, and balance.

- Safety concerns: Always wear appropriate PPE, follow safety protocols, and inspect the machine before operation.

5. What are the safety precautions that should be taken when operating a rivet machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Ensure the machine is properly grounded and electrically isolated before operating.

- Inspect the machine regularly for any damage or loose parts.

- Keep the work area clean and free of debris.

- Never operate the machine under the influence of drugs or alcohol.

6. How do you maintain and calibrate a rivet machine?

Maintenance

- Regularly clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine for any signs of wear or damage and replace worn parts as necessary.

Calibration

- Use a rivet calibration gauge to ensure the machine is setting rivets to the correct dimensions.

- Follow the manufacturer’s recommended calibration procedures and adjust the machine accordingly.

7. Describe the different types of rivet guns and their applications.

Manual rivet guns

- Hand-operated tools used for setting small rivets, suitable for low-volume or occasional use.

Pneumatic rivet guns

- Air-powered tools that offer faster and more consistent riveting, ideal for medium- to high-volume production.

Hydraulic rivet guns

- High-force tools used for setting large or heavy-duty rivets, commonly found in industrial applications.

Battery-powered rivet guns

- Cordless tools that provide portability and convenience, suitable for remote or hard-to-reach areas.

8. What is the difference between a rivet and a bolt?

- Head: Rivets have a single formed head, while bolts have two heads (a head and a nut).

- Installation: Rivets are typically installed with a rivet machine or gun, while bolts are tightened using a wrench or other tool.

- Disassembly: Rivets are permanent connections and cannot be easily removed without damaging the materials, while bolts can be loosened and removed for maintenance or repairs.

- Load distribution: Rivets distribute loads more evenly than bolts, making them suitable for applications where stress distribution is important.

9. How do you determine the correct rivet size and type for a specific application?

- Consider the materials being joined and their thickness.

- Determine the required load-bearing capacity of the joint.

- Choose a rivet type that is compatible with the materials and application.

- Select the appropriate rivet size based on the hole diameter and the thickness of the materials.

10. Describe the different methods for inspecting riveted joints.

Visual inspection

- Examine the joint for any visible defects, such as cracks, loose rivets, or misalignment.

Non-destructive testing (NDT)

- Ultrasonic testing: Uses sound waves to detect internal defects or voids.

- Radiographic testing: Uses X-rays or gamma rays to reveal internal defects.

Destructive testing

- Tension testing: Tests the strength of the joint by applying a pulling force.

- Shear testing: Tests the joint’s resistance to sideways forces.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rivet Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rivet Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rivet Machine Operators are responsible for operating and maintaining rivet machines, which are used to join metal sheets and other materials together. They work in a variety of industries, including automotive, aerospace, and construction.

1. Set up and operate rivet machines

Operators set up and operate rivet machines to join metal sheets and other materials together. They must be able to read and interpret technical drawings and specifications.

- Load and unload materials onto the machine

- Adjust machine settings according to the type of material being joined

- Operate the machine to join the materials together

2. Inspect and maintain rivet machines

Operators are responsible for inspecting and maintaining rivet machines to ensure that they are operating safely and efficiently. They must be able to identify and troubleshoot problems with the machine.

- Inspect the machine for damage or wear

- Clean and lubricate the machine

- Replace worn or damaged parts

3. Ensure quality control

Operators are responsible for ensuring the quality of the finished product. They must be able to inspect the finished product for defects and make adjustments to the machine as needed.

- Inspect the finished product for defects

- Make adjustments to the machine to improve the quality of the finished product

- Document the quality of the finished product

4. Follow safety procedures

Operators must follow all safety procedures when operating rivet machines. They must be aware of the potential hazards associated with the machine and take steps to avoid accidents.

- Wear appropriate safety gear

- Follow lockout/tagout procedures

- Be aware of the potential hazards associated with the machine

Interview Tips

In preparation for your interview for a Rivet Machine Operator position, there are several tips you can follow to increase your chances of success.

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you to better understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, Glassdoor, and other online resources.

- Visit the company’s website to learn about their history, mission, and values.

- Read reviews of the company on Glassdoor and other online resources to get a sense of the company culture.

- Research the specific job title to learn about the key responsibilities and requirements.

2. Prepare answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to prepare answers to these questions in advance so that you can deliver them confidently and concisely. You can find a list of common interview questions online or in a book about job hunting.

- Practice answering common interview questions out loud.

- Get feedback from a friend or family member on your answers.

- Tailor your answers to the specific job you are applying for.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the job and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Arrive at the interview location 10-15 minutes early.

- Bring a pad of paper and a pen to take notes.

4. Be confident and enthusiastic

Interviewers are looking for candidates who are confident and enthusiastic about the job. Be yourself and let your personality shine through. Show the interviewer that you are excited about the opportunity to work for the company.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic.

Next Step:

Now that you’re armed with the knowledge of Rivet Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rivet Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini