Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rivet Tapping Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

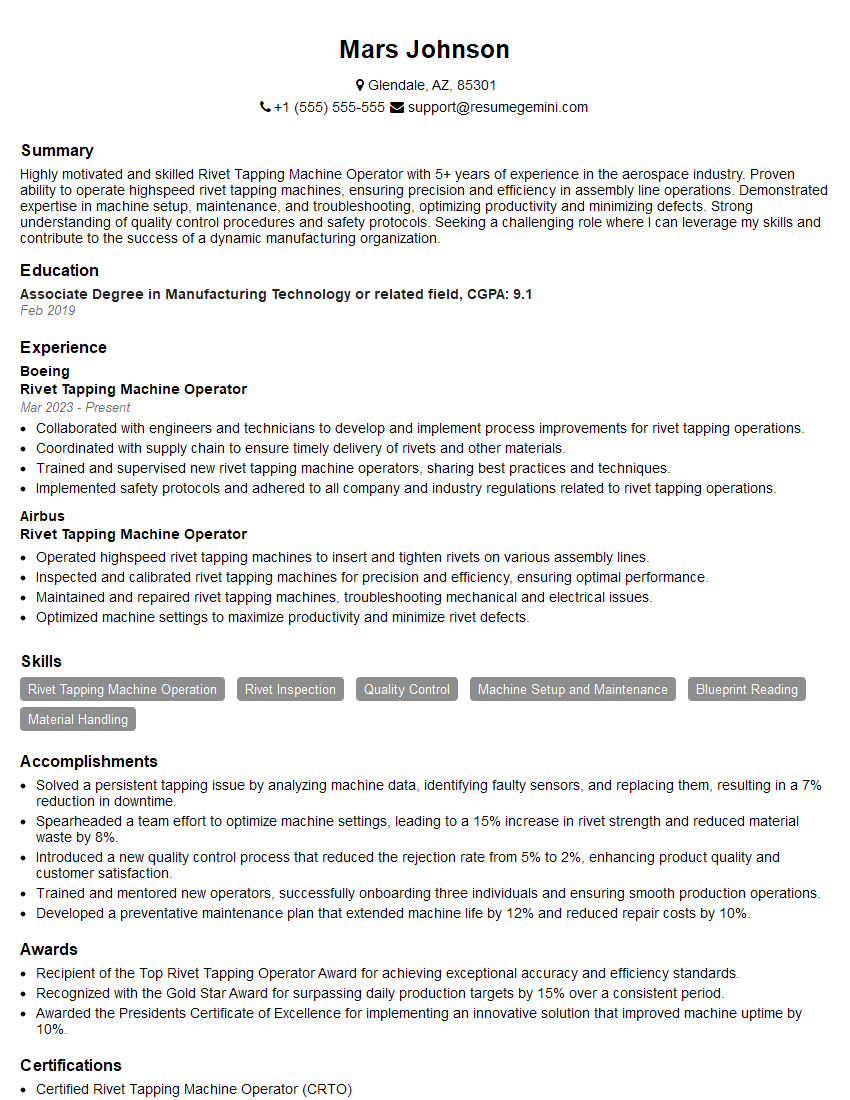

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rivet Tapping Machine Operator

1. What are the different types of rivet tapping machines?

- Pneumatic

- Electric

- Hydraulic

- Mechanical

2. What are the key components of a rivet tapping machine?

Mechanical Components

- Frame

- Spindle

- Table

- Head

Electrical Components

- Motor

- Controller

- Wiring

- Sensors

3. What are the common problems that can occur with rivet tapping machines?

- Broken or worn taps

- Misaligned parts

- Improper torque settings

- Overheating

4. How do you troubleshoot and repair a rivet tapping machine?

- First, identify the problem.

- Check for broken or worn parts.

- Make sure that the parts are properly aligned.

- Check the torque settings.

- Allow the machine to cool down if it is overheating.

- Replace any broken or worn parts.

- Realign the parts as necessary.

- Adjust the torque settings.

- Allow the machine to cool down completely before restarting.

5. What safety precautions should be taken when operating a rivet tapping machine?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Inspect the machine before each use.

- Do not operate the machine if it is damaged.

- Be aware of the moving parts of the machine.

- Do not place your hands near the tapping area.

- Follow all manufacturer’s instructions.

6. What is the difference between a rivet and a screw?

- Rivets are permanent fasteners, while screws can be removed and reused.

- Rivets are installed by hammering or pressing, while screws are installed by turning.

- Rivets have a solid shank, while screws have a threaded shank.

- Rivets are typically used in applications where strength and durability are important, while screws are typically used in applications where frequent disassembly is required.

7. What are the different types of rivets?

- Solid rivets

- Tubular rivets

- Split rivets

- Blind rivets

- Self-piercing rivets

8. What are the different materials that rivets can be made of?

- Steel

- Aluminum

- Copper

- Brass

- Stainless steel

- Monel

- Inconel

9. What are the different applications for rivet tapping machines?

- Automotive industry

- Aerospace industry

- Construction industry

- Appliance industry

- Electronics industry

- Furniture industry

- Medical industry

10. What are the qualities of a good rivet tapping machine operator?

- Attention to detail

- Manual dexterity

- Problem-solving skills

- Ability to work independently

- Ability to work in a team environment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rivet Tapping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rivet Tapping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rivet Tapping Machine Operator is responsible for operating a rivet tapping machine to create threaded holes and insert rivets. These professionals play a vital role in the manufacturing process, ensuring the accuracy and precision of critical components.

1. Machine Operation

Operate and maintain rivet tapping machines, ensuring their proper functioning

- Set up and adjust machine parameters according to specifications

- Load and unload materials and components

- Monitor and control the tapping process

2. Rivet Installation

Insert rivets into pre-tapped holes using the tapping machine

- Select the appropriate rivets for the job

- Feed rivets into the machine

- Ensure correct rivet placement and insertion

3. Quality Control

Inspect and verify the quality of tapped holes and rivets

- Check for proper thread size and depth

- Inspect rivets for correct fit and tightness

- Identify and correct any defects

4. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting on rivet tapping machines

- Lubricate and clean equipment

- Identify and resolve minor malfunctions

- Report major issues to supervisors for assistance

Interview Tips

To prepare effectively for your interview as a Rivet Tapping Machine Operator, consider the following tips:

1. Research the Company and Position

Gather information about the company’s industry, products, and culture. Review the job description thoroughly to understand the specific responsibilities and requirements

- Check the company website, industry publications, and social media

- Familiarize yourself with the different types of rivet tapping machines and their applications

- Prepare to discuss your knowledge of quality control techniques

2. Highlight Relevant Skills and Experience

Emphasize your experience and skills in operating rivet tapping machines and quality control procedures. If you have experience working with different types of materials, including metals, plastics, and composites, be sure to mention it.

- Provide specific examples of your work, quantifying your accomplishments whenever possible

- Be prepared to discuss your problem-solving and analytical abilities

- Explain how your attention to detail and precision make you a suitable candidate for the role

3. Practice Answering Common Interview Questions

Anticipate and prepare for commonly asked interview questions, such as:

- Tell me about your experience operating rivet tapping machines.

- Describe your understanding of the rivet tapping process, including different materials and applications.

- How do you ensure quality and accuracy in your work?

- What are some of the challenges you have faced in your previous role and how did you overcome them?

4. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview. Arrive on time to show respect for the interviewer and their time

- Consider wearing business attire or clean, well-pressed work clothes

- Arrive a few minutes early to allow for any unexpected delays

- Be polite and respectful to everyone you meet during the interview process

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rivet Tapping Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.