Are you gearing up for a career in Rivet Tester? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rivet Tester and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

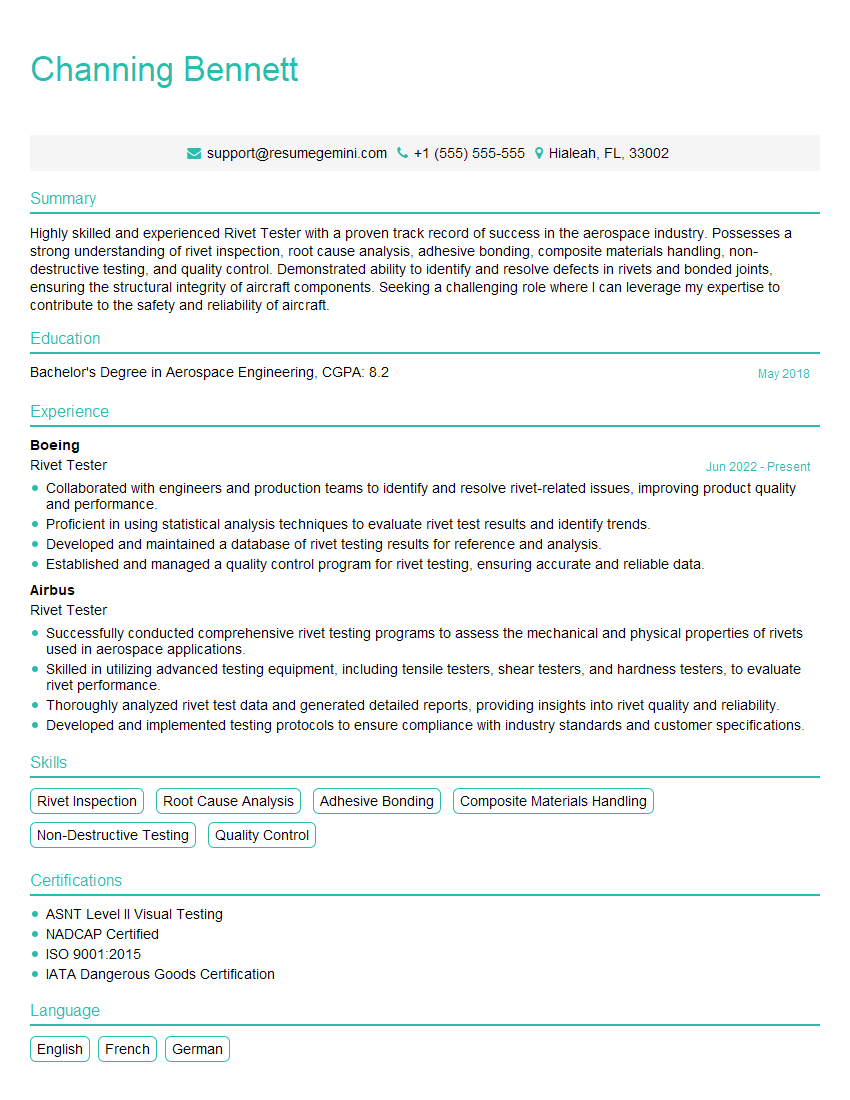

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rivet Tester

1. Describe the basic principles of riveting and the different types of rivets used in various applications.

Riveting is a permanent mechanical fastening technique used to join two or more pieces of metal together. It involves inserting a rivet into a pre-drilled hole, then deforming the rivet’s end to form a head on the opposite side, securing the materials together.

- Solid Rivets: Simple, one-piece rivets with a solid shank. They provide high shear and tensile strength.

- Blind Rivets: Used when access is limited to one side of the material. The rivet has a hollow shank and a mandrel that expands the shank when pulled, forming a head.

- Semi-Tubular Rivets: Similar to solid rivets, but with a hollow shank. They offer flexibility, allowing for some misalignment between the materials.

2. Explain the various types of rivet testing methods and their purposes.

Tensile Testing

- Assesses the rivet’s ability to withstand axial tensile forces without breaking.

Shear Testing

- Evaluates the rivet’s resistance to forces applied parallel to the shank.

Fatigue Testing

- Simulates repeated loading cycles to determine the rivet’s endurance limit.

Stress Relaxation Testing

- Measures the decrease in clamping force over time due to material creep or relaxation.

3. Describe the factors that influence the strength and reliability of a riveted joint.

- Rivet Material: Strength, ductility, and corrosion resistance of the rivet.

- Rivet Size and Shape: Shank diameter, head size, and overall geometry.

- Hole Preparation: Proper hole size, tolerances, and surface finish.

- Rivet Installation: Controlled force, proper setting techniques, and avoiding overtightening.

- Environmental Factors: Temperature, load conditions, and corrosion exposure.

4. Discuss the importance of rivet quality control and how it is ensured.

Rivet quality control is crucial to ensure the integrity and safety of riveted joints. It involves the following steps:

- Raw Material Inspection: Checking the rivet’s material composition, dimensions, and surface finish.

- In-Process Inspection: Monitoring rivet forming, heat treatment, and plating processes.

- Finished Product Testing: Conducting various tests to assess the rivet’s strength, durability, and corrosion resistance.

- Documentation and Traceability: Maintaining records of inspections, test results, and batch information for traceability.

5. Describe the safety precautions that should be taken when working with rivets and riveting equipment.

- Eye Protection: Always wear safety glasses or goggles.

- Hand Protection: Use gloves to protect from sharp edges and hot rivets.

- Proper Ventilation: Ensure adequate ventilation during riveting to avoid inhaling fumes.

- Electrical Safety: Use properly grounded equipment and follow electrical safety guidelines.

- Noise Protection: Wear earplugs or ear muffs to protect from noise generated by riveting.

6. Explain the different techniques used for riveting, such as manual riveting, power riveting, and robotic riveting.

Manual Riveting

- Involves using a hammer and bucking bar to form the rivet head.

Power Riveting

- Employs air-powered or hydraulic tools to drive and set rivets.

Robotic Riveting

- Highly automated process that uses robotic arms to precisely insert and set rivets.

7. Discuss the challenges and troubleshooting techniques for common riveting problems, such as loose or missing rivets.

Loose Rivets

- Causes: Undersized hole, insufficient force during setting, or material creep.

- Troubleshooting: Re-tighten or replace the rivet, check hole size and setting force.

Missing Rivets

- Causes: Incorrect hole location, improper rivet insertion, or vibration.

- Troubleshooting: Inspect the rivet hole, check rivet installation technique, and secure the joint against vibration.

8. Describe the latest advancements in riveting technology, such as self-piercing rivets and adhesive bonding.

Self-Piercing Rivets

- Designed to pierce through the material and form a strong joint without pre-drilling.

Adhesive Bonding

- Involves using structural adhesives to bond materials together, providing an alternative to traditional riveting.

9. Discuss the role of rivet testers in ensuring the quality and reliability of riveted joints.

- Verification: Testing rivets to meet the specified requirements.

- Problem Identification: Identifying and diagnosing issues with rivet performance.

- Process Optimization: Providing data to improve riveting processes and quality control.

- Safety: Ensuring the integrity of riveted joints for safety-critical applications.

10. What are the key performance indicators (KPIs) that you focus on in your role as a rivet tester?

- Accuracy: Ensuring accurate test results within specified tolerances.

- Efficiency: Conducting tests efficiently without compromising accuracy.

- Reliability: Providing consistent and reliable test data.

- Problem Solving: Effectively resolving issues with test equipment or procedures.

- Compliance: Adhering to industry standards and regulatory requirements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rivet Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rivet Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rivet Tester is responsible for conducting tests on rivets and other fasteners to ensure they meet quality standards. Key job responsibilities of a Rivet Tester include:

1. Inspection and Testing

Inspect rivets and other fasteners for defects such as burrs, cracks, and improper dimensions.

- Conduct tensile strength tests to determine the maximum load a rivet can withstand before failing.

- Perform shear strength tests to measure the force required to break a rivet.

- Carry out fatigue tests to simulate the effects of repeated loading and unloading on a rivet.

2. Data Analysis and Reporting

Analyze test results and report findings to management or customers.

- Prepare written reports that detail test conditions, results, and conclusions.

- Maintain records of all tests conducted and results.

3. Equipment Maintenance and Calibration

Maintain and calibrate testing equipment to ensure accuracy and reliability.

- Perform regular maintenance on testing machines, such as cleaning, lubrication, and calibration.

- Troubleshoot and repair equipment as needed.

4. Quality Assurance

Monitor production processes and implement quality control measures to ensure that rivets meet specifications.

- Conduct random inspections of rivets and other fasteners during production.

- Identify and correct any quality issues in a timely manner.

- Participate in quality improvement initiatives.

Interview Preparation Tips

Preparing for a Rivet Tester interview can help you present yourself as a qualified and knowledgeable candidate. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a good understanding of the company’s culture, values, and the specific responsibilities of the role.

- Visit the company’s website to learn about their products, services, and history.

- Read industry news and articles to stay up-to-date on the latest trends in the field.

- Connect with current or former employees on LinkedIn to gain insights into the company culture and work environment.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to be asked, regardless of the position you are applying for. It is important to practice answering these questions clearly and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- Do you have any questions for me?

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the position you are applying for. Use specific examples to demonstrate how you have successfully performed similar tasks in the past.

- Emphasize your technical skills, such as your knowledge of testing equipment and procedures.

- Highlight your analytical skills and your ability to interpret data and draw conclusions.

- Showcase your communication skills and your ability to work effectively with others.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. Arrive on time and be prepared to make a good impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rivet Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.