Are you gearing up for an interview for a Riveter Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Riveter Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

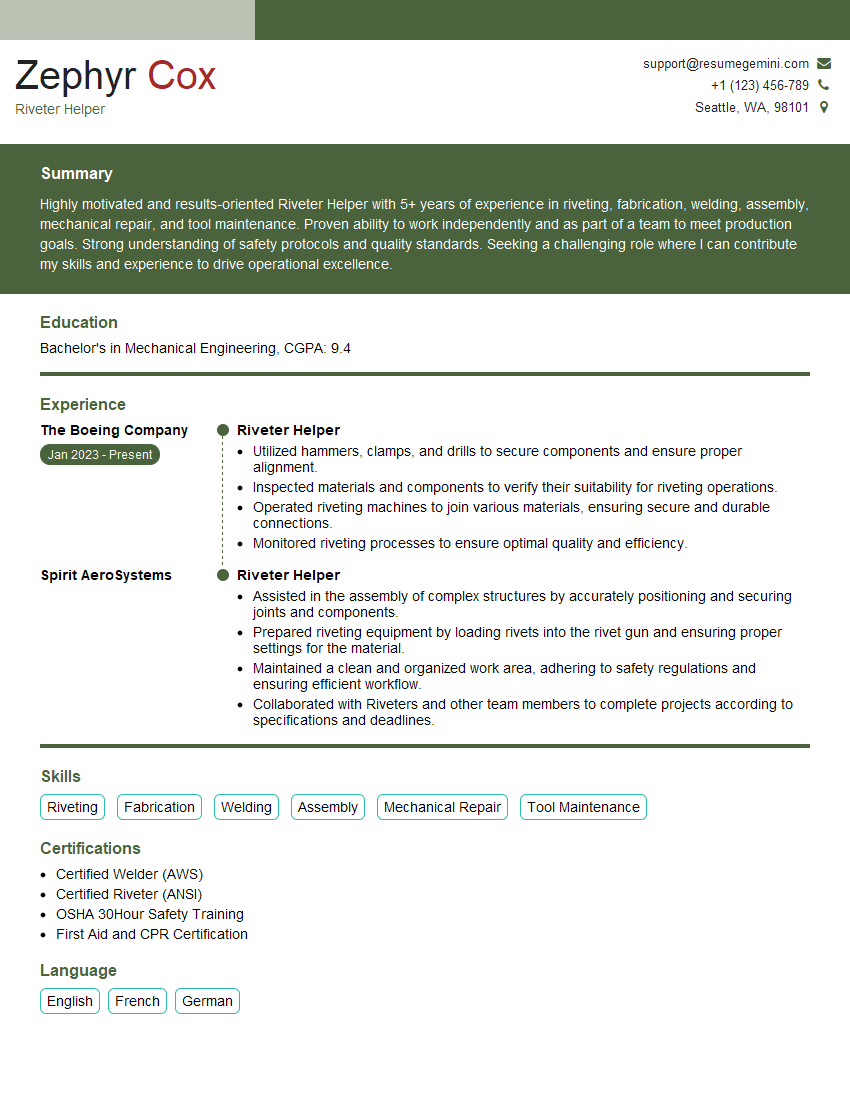

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Riveter Helper

1. What are the different types of riveting tools and when to use each one?

The different types of riveting tools include:

- Hand riveters: These are manually operated and are suitable for small-scale riveting projects.

- Pneumatic riveters: These are powered by compressed air and are more powerful than hand riveters. They can be used for riveting large and thick materials.

- Hydraulic riveters: These are powered by hydraulic pressure and are the most powerful type of riveting tool. They are used for riveting large and heavy materials.

The choice of riveting tool depends on the size and thickness of the material to be riveted, as well as the volume of work to be done.

2. What are the safety precautions to follow when using riveting tools?

Proper Protective Gear

- Wear safety glasses to protect your eyes from flying debris.

- Wear earplugs or ear muffs to protect your hearing from loud noise.

- Wear gloves to protect your hands from sharp edges.

Handle the Tool Safely

- Inspect the riveting tool before each use to make sure it is in good working condition.

- Never point the riveting tool at anyone.

- Keep the riveting tool away from flammable materials.

3. What are the different types of rivets and how to choose the right one for the job?

The different types of rivets include:

- Solid rivets: These are the most common type of rivet and are made from a single piece of metal.

- Tubular rivets: These rivets have a hollow center and are used for riveting thin materials.

- Blind rivets: These rivets are used for riveting when access to only one side of the material is available.

The choice of rivet depends on the thickness of the material to be riveted, the strength required, and the accessibility of the riveting area.

4. How to inspect a riveted joint for quality?

To inspect a riveted joint for quality, you will need to check the following:

- The rivets should be properly seated: The head of the rivet should be flush with the surface of the material.

- The rivet should be tight: There should be no movement between the rivet and the material.

- The rivet should be free of cracks: Cracks in the rivet can cause the joint to fail.

You can also use a non-destructive testing method such as ultrasonic testing or radiography to inspect the riveted joint for internal defects.

5. How to troubleshoot common riveting problems?

Common riveting problems include:

- Loose rivets: This can be caused by using the wrong size rivet, not properly seating the rivet, or not tightening the rivet enough.

- Cracked rivets: This can be caused by using the wrong type of rivet, over-tightening the rivet, or riveting materials that are too thick.

- Broken rivets: This can be caused by using the wrong size rivet, not properly seating the rivet, or riveting materials that are too thick.

To troubleshoot these problems, you will need to identify the cause of the problem and then take the appropriate corrective action.

6. What are the different ways to finish a riveted joint?

The different ways to finish a riveted joint include:

- Countersunk: The head of the rivet is countersunk below the surface of the material.

- Raised: The head of the rivet is raised above the surface of the material.

- Flat: The head of the rivet is flush with the surface of the material.

The choice of finish depends on the appearance and strength requirements of the joint.

7. What are the different materials used for riveting?

The different materials used for riveting include:

- Steel: Steel is the most common material used for riveting.

- Aluminum: Aluminum is a lightweight and corrosion-resistant material that is often used for riveting aircraft and other structures.

- Copper: Copper is a conductive material that is often used for riveting electrical components.

- Brass: Brass is a corrosion-resistant material that is often used for riveting marine applications.

The choice of material depends on the strength, corrosion resistance, and electrical conductivity requirements of the joint.

8. What are the different applications of riveting?

Riveting is used in a wide variety of applications, including:

- Construction: Riveting is used to connect steel beams and other structural components.

- Aircraft: Riveting is used to connect aircraft skins and other components.

- Marine: Riveting is used to connect metal plates and other components on ships and boats.

- Electrical: Riveting is used to connect electrical components and wires.

Riveting is a versatile and reliable method of joining metal components.

9. What are the advantages and disadvantages of riveting?

Advantages

- Strong and durable: Riveted joints are strong and durable, and can withstand high loads.

- Versatile: Riveting can be used to join a wide variety of materials, including metal, plastic, and wood.

- Reliable: Riveted joints are reliable and can withstand harsh environmental conditions.

Disadvantages

- Permanent: Riveted joints are permanent and cannot be easily disassembled.

- Can damage materials: Riveting can damage thin or delicate materials.

- Can be expensive: Riveting can be expensive, especially for large or complex projects.

10. What are the career opportunities for a Riveter Helper?

The career opportunities for a Riveter Helper include:

- Riveter: Riveters install and repair rivets on various structures and components.

- Boilermaker: Boilermakers fabricate and repair boilers, tanks, and other pressure vessels.

- Welder: Welders join metal components together using welding techniques.

- Machinist: Machinists operate machine tools to create and repair metal parts.

With experience and training, a Riveter Helper can advance to a higher-paying position in the metalworking industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Riveter Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Riveter Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Riveter Helpers are the backbone of many construction and manufacturing operations. They perform a variety of tasks to support riveters, ensuring that riveting operations run smoothly and efficiently.

The key job responsibilities of a Riveter Helper typically include:

1. Assisting Riveters

Assisting riveters with the preparation and installation of rivets.

- Gathering and bringing materials to riveters.

- Preparing rivets for installation by cutting, straightening, and heating them.

- Holding and positioning rivets while they are being installed.

- Removing spent rivets and cleaning up work areas.

2. Operating Equipment

Operating riveting equipment, such as rivet guns and riveters.

- Setting up and adjusting riveting equipment.

- Operating rivet guns and riveters to install rivets.

- Maintaining and repairing riveting equipment.

3. Maintaining Work Areas

Maintaining work areas clean and safe.

- Keeping work areas free of debris and tripping hazards.

- Ensuring that all tools and equipment are properly stored.

- Following safety procedures and regulations.

4. Other Duties

Performing other duties as assigned.

- Assisting with other tasks as needed, such as welding, grinding, and painting.

- Keeping records of riveting operations.

- Reporting any problems or concerns to supervisors.

Interview Tips

Preparing for a Riveter Helper interview can help you make a positive impression on the interviewer and increase your chances of getting the job. Here are some interview tips and hacks to help you ace your interview:

1. Research the Job and Company

Before the interview, take some time to research the Riveter Helper position and the company you are applying to.

- Learn about the company’s history, products, and services.

- Review the job description carefully and identify the key skills and qualifications.

- Practice answering common interview questions related to your skills, experience, and qualifications.

2. Be Yourself and Be Confident

It is important to be yourself during the interview and to be confident in your abilities.

- Answer questions honestly and concisely.

- Highlight your relevant skills and experience.

- Maintain eye contact and speak clearly and confidently.

3. Be Prepared to Answer Technical Questions

During the interview, you may be asked technical questions about riveting operations and equipment.

- Review the basic principles of riveting and the different types of rivets.

- Be familiar with the different types of riveting equipment and their uses.

- Practice answering questions about your experience with riveting equipment.

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the job and the company.

- Ask about the company’s culture and values.

- Inquire about the training and development opportunities available.

- Ask about the company’s plans for growth and expansion.

5. Follow Up

After the interview, it is important to follow up with the interviewer.

- Send a thank-you note within 24 hours.

- Reiterate your interest in the job.

- Let the interviewer know that you are available for further discussion.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Riveter Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.