Are you gearing up for a career in Road Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Road Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

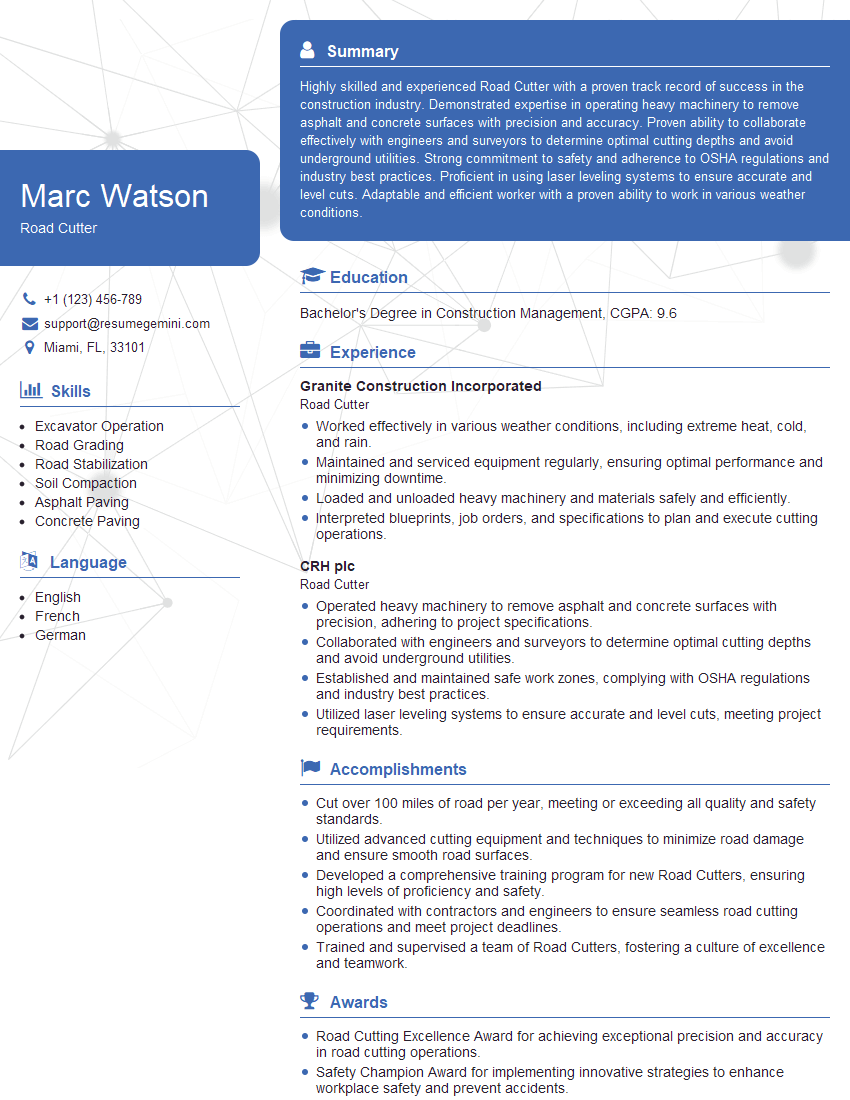

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Road Cutter

1. What are the different types of road cutters and their applications?

- Walk-behind road cutters: These are handheld machines that are used for small to medium-sized cutting projects. They are relatively easy to operate and can be used in tight spaces.

- Ride-on road cutters: These machines are larger and more powerful than walk-behind road cutters. They are used for larger cutting projects and can be operated from a seated position.

- Self-propelled road cutters: These machines are the most powerful type of road cutters. They are used for large-scale cutting projects and can cut through concrete and asphalt with ease.

2. What are the safety precautions that should be taken when operating a road cutter?

subheading of the answer

- Always wear appropriate safety gear, including a hard hat, safety glasses, and earplugs.

- Inspect the road cutter before each use to make sure it is in good working condition.

- Never operate a road cutter under the influence of drugs or alcohol.

- Be aware of your surroundings and be careful not to damage underground utilities.

- Always follow the manufacturer’s instructions for operating the road cutter.

subheading of the answer

- In addition to the general safety precautions, there are also specific safety precautions that should be taken when operating a road cutter in certain conditions. For example, when operating a road cutter in wet conditions, it is important to wear waterproof clothing and to take extra care to avoid slipping.

- When operating a road cutter in cold conditions, it is important to wear warm clothing and to take breaks to warm up as needed.

3. What are the different types of blades that can be used on a road cutter?

- Diamond blades: Diamond blades are the most common type of blade used on road cutters. They are made of a diamond-coated steel core and are very durable.

- Carbide blades: Carbide blades are made of a tungsten carbide core and are less durable than diamond blades. However, they are less expensive and can be used to cut a wider variety of materials.

- Abrasive blades: Abrasive blades are made of a bonded abrasive material, such as silicon carbide or aluminum oxide. They are the least expensive type of blade and are used for cutting soft materials, such as asphalt.

4. How do you determine the correct blade for a particular cutting job?

- The type of material being cut

- The thickness of the material being cut

- The desired cutting speed

- The budget

5. What are the different types of cuts that can be made with a road cutter?

- Straight cuts: Straight cuts are the most common type of cut made with a road cutter. They are used to cut straight lines in concrete and asphalt.

- Curved cuts: Curved cuts are used to cut curves in concrete and asphalt. They are more difficult to make than straight cuts, but they can be used to create a variety of shapes and designs.

- Beveled cuts: Beveled cuts are used to cut angles in concrete and asphalt. They are often used to create ramps and slopes.

6. What are the different factors that affect the cutting speed of a road cutter?

- The type of blade being used

- The horsepower of the road cutter

- The speed of the road cutter

- The thickness of the material being cut

- The hardness of the material being cut

7. What are the different types of maintenance that need to be performed on a road cutter?

- Daily maintenance: Daily maintenance includes tasks such as checking the oil level, cleaning the air filter, and inspecting the blades.

- Weekly maintenance: Weekly maintenance includes tasks such as changing the oil, greasing the bearings, and inspecting the belts.

- Monthly maintenance: Monthly maintenance includes tasks such as checking the spark plugs, cleaning the fuel filter, and inspecting the hydraulic system.

8. How do you troubleshoot a road cutter that is not working properly?

- Check the power source: Make sure that the road cutter is plugged into a working power outlet.

- Check the fuel level: If the road cutter is gas-powered, make sure that there is enough fuel in the tank.

- Check the oil level: Make sure that the road cutter has enough oil.

- Check the air filter: A dirty air filter can restrict airflow and cause the road cutter to run poorly.

- Check the spark plugs: Fouled spark plugs can prevent the road cutter from starting.

- Check the belts: Loose or damaged belts can cause the road cutter to lose power.

9. What are the different types of road cutter attachments?

- Scarifiers: Scarifiers are used to remove old or damaged asphalt from a road surface.

- Levelers: Levelers are used to level uneven road surfaces.

- Grinders: Grinders are used to smooth out rough road surfaces.

- Crack sealers: Crack sealers are used to fill cracks in road surfaces.

10. What are the different types of road cutter manufacturers?

- Bartell Global: Bartell Global is a leading manufacturer of road cutters and other construction equipment.

- Husqvarna: Husqvarna is a well-known manufacturer of a wide range of outdoor power equipment, including road cutters.

- Makita: Makita is a leading manufacturer of power tools, including road cutters.

- STIHL: STIHL is a leading manufacturer of outdoor power equipment, including road cutters.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Road Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Road Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Road Cutters play a crucial role in construction and maintenance projects, using specialized equipment to cut through various types of pavement and create precise incisions for repairs, utility installations, or road modifications.

1. Operating Road Cutting Equipment

Skilled operation of road cutting machines, including concrete saws, asphalt cutters, and scarifiers, is essential. This involves setting up and calibrating the equipment, adjusting blade depth and speed, and ensuring safe and efficient operation.

- Demonstrate proficiency in handling different types of road cutting machines.

- Maintain a high level of precision in cutting operations, adhering to specified depths and alignments.

2. Planning and Layout

Meticulous planning and layout are vital to ensure accurate and efficient road cutting. This includes studying project plans, determining cutting lines, and marking the work area.

- Thoroughly review construction plans and specifications to identify the scope of work.

- Accurately mark and lay out cutting lines using appropriate tools and techniques.

3. Safety and Equipment Maintenance

Upholding safety protocols and maintaining equipment in optimal condition are paramount. This involves following established safety procedures, wearing appropriate protective gear, and performing routine maintenance.

- Adhere strictly to safety regulations and guidelines.

- Conduct regular equipment inspections and perform necessary maintenance tasks.

4. Collaboration and Communication

Effective collaboration and communication with engineers, supervisors, and other team members are essential for successful project execution. This involves understanding project requirements, coordinating work activities, and reporting progress.

- Maintain open communication with project managers and supervisors.

- Effectively convey project updates and any challenges encountered.

Interview Tips

Preparing thoroughly for a Road Cutter interview can significantly enhance your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Role

Demonstrate your interest in the company and the specific Road Cutter position by researching their website, LinkedIn page, and industry news. Familiarize yourself with their projects, values, and the responsibilities of the role.

- Tailor your answers to the specific requirements and culture of the company.

- Show enthusiasm for the role and explain why you are a suitable fit.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating road cutting equipment, including specific models and techniques. Showcase your experience in planning and layout, safety procedures, and equipment maintenance.

- Provide quantifiable examples of your accomplishments in previous projects.

- Quantify your results and highlight your contributions to project success.

3. Prepare for Technical Questions

Be prepared to answer technical questions related to road cutting equipment, safety protocols, and industry best practices. Practice explaining complex concepts clearly and concisely.

- Anticipate questions about different types of road cutting machines and their applications.

- Research industry standards and guidelines for road cutting operations.

4. Practice Common Interview Questions

Familiarize yourself with common interview questions and prepare thoughtful responses that showcase your skills, experience, and motivation. This could include questions about your strengths, weaknesses, and why you are interested in the role.

- Practice answering questions in a structured and engaging manner.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Road Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!