Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Road Roller Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Road Roller Operator so you can tailor your answers to impress potential employers.

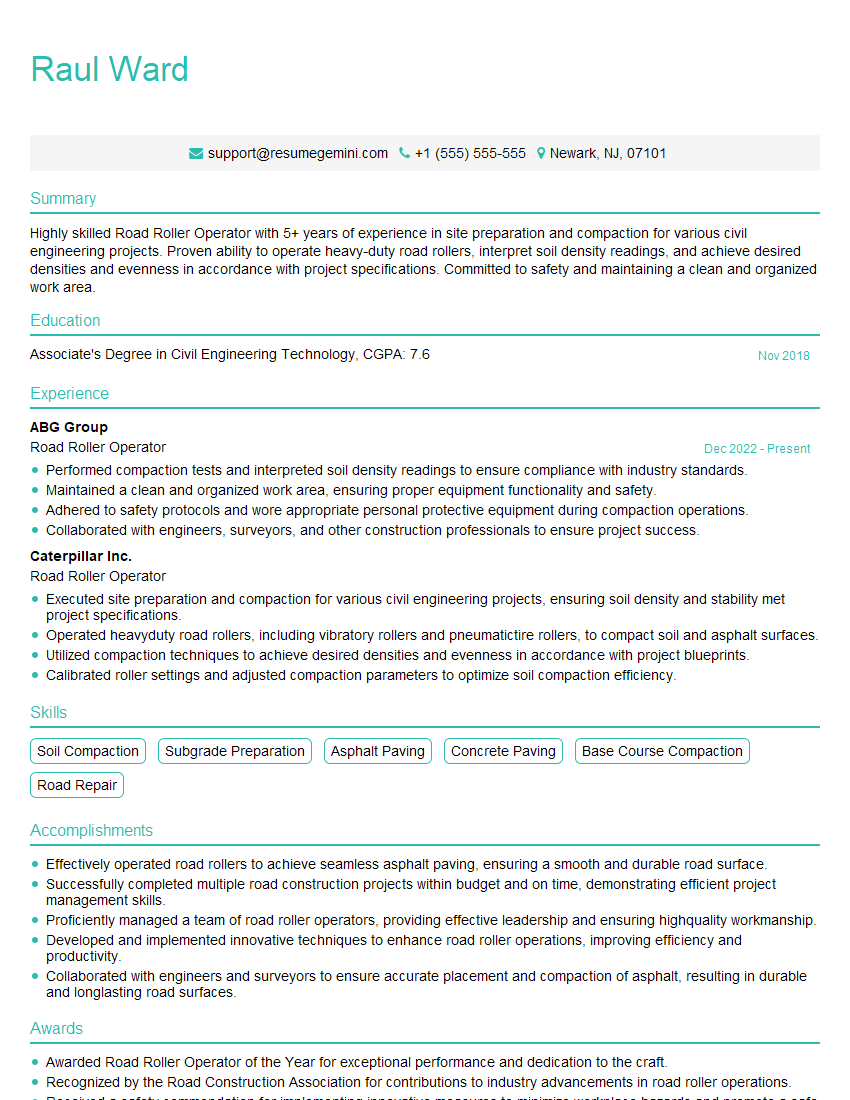

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Road Roller Operator

1. What are the different types of road rollers and their uses?

There are several types of road rollers, each designed for specific purposes. Here are some common types:

- Tandem Roller: Used for compacting asphalt and soil on smaller projects, such as driveways, parking lots, and sidewalks. It has two steel drums, one in front and one in the back, that provide compaction.

- Three-Wheeled Roller: Suitable for compacting larger areas, such as roads and highways. It has a large steel drum in the front and two smaller pneumatic tires in the back, providing a combination of compaction and maneuverability.

- Vibratory Roller: Used for compacting granular materials like sand and gravel. It has a vibrating drum that shakes the ground, increasing compaction efficiency.

- Pneumatic Tire Roller: Designed for compacting asphalt and soil on sensitive surfaces, such as bridges and airport runways. It has large, inflatable tires that distribute the weight evenly, reducing surface damage.

2. What are the key factors to consider when selecting the right road roller for a project?

Factors to Consider:

- Project Size and Type: Choose a roller that matches the size and type of project, considering the area to be compacted and the materials used.

- Ground Conditions: Assess the soil or asphalt conditions to determine the appropriate compaction method and roller weight.

- Compaction Requirements: Consider the desired level of compaction and the roller’s ability to achieve it.

- Maneuverability: Select a roller that can easily navigate the project site, especially if there are tight spaces or obstacles.

- Budget and Availability: Determine the budget for the roller and check the availability of the desired type.

3. Describe the process of compacting asphalt using a road roller.

Compacting asphalt using a road roller typically involves the following steps:

- Preparing the Surface: Ensure the asphalt is spread evenly and has the correct temperature for compaction.

- Initial Compaction: Use a tandem roller to perform the initial compaction, passing over the asphalt multiple times to achieve a smooth and dense surface.

- Intermediate Compaction: Switch to a vibratory roller for intermediate compaction. The vibrations help settle the asphalt particles and increase density.

- Final Compaction: Use a heavy three-wheeled roller for final compaction. This step ensures maximum density and a strong, stable asphalt surface.

- Cooling and Curing: Allow the asphalt to cool and cure properly to achieve its full strength and durability.

4. What are the common problems that can arise during road roller operation and how do you troubleshoot them?

-

Problem: Roller not moving smoothly

Troubleshooting: Check hydraulic fluid levels, inspect hoses for leaks, and ensure proper tire pressure.

Problem: Excessive vibration

Troubleshooting: Calibrate the vibratory system, inspect bearings and mounts for wear, and ensure proper lubrication.

Problem: Uneven compaction

Troubleshooting: Adjust roller weight distribution, check drum pressure, and ensure the ground is properly prepared.

Problem: Roller overheating

Troubleshooting: Check coolant levels, inspect the radiator for blockages, and ensure proper engine maintenance.

Problem: Electrical issues

Troubleshooting: Inspect wiring, fuses, and switches. Check battery terminals and connections.

5. What safety precautions are essential when operating a road roller?

- Wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Conduct a thorough site inspection before starting work.

- Ensure the roller is in good working condition and regularly maintained.

- Be aware of surroundings and potential hazards.

- Operate the roller at safe speeds and avoid sudden movements.

- Never leave the roller unattended while running.

- Follow all manufacturer’s instructions and safety protocols.

6. Can you explain the importance of compaction in road construction?

Compaction is crucial in road construction for the following reasons:

- Increases Strength and Durability: Compaction removes air voids, increasing the density and strength of the road surface, making it less susceptible to cracking and deformation.

- Reduces Permeability: Compaction reduces the porosity of the road surface, making it less permeable to water and other fluids, minimizing damage from moisture and frost.

- Improves Stability: Compacted roads provide a stable base for vehicles, reducing the risk of rutting and potholes.

- Extends Road Life: Proper compaction helps prevent premature deterioration and extends the lifespan of the road, reducing maintenance costs.

7. What are the different types of compaction tests used to assess the quality of compacted soil or asphalt?

- Nuclear Density Gauge: Uses radioactive sources to measure soil or asphalt density and moisture content.

- Sand Cone Test: Measures the volume of a sand cone formed in a hole excavated in the compacted material.

- Plate Load Test: Applies a known load to a plate placed on the compacted surface to measure its bearing capacity.

- Falling Weight Deflectometer (FWD): Uses a falling weight to measure the deflection of the compacted surface.

- Light Weight Deflectometer (LWD): Similar to FWD, but uses a lighter weight and is suitable for testing thin layers.

8. How do you ensure that the compacted surface meets the specified density requirements?

- Proper Roller Selection: Choose the right roller type and weight for the material and compaction requirements.

- Adequate Compaction Passes: Determine the optimal number of roller passes needed to achieve the desired density.

- Moisture Control: Ensure the soil or asphalt has the correct moisture content for optimal compaction.

- Compaction Testing: Conduct compaction tests at regular intervals to monitor progress and make adjustments as needed.

- Documentation: Keep detailed records of compaction activities, including test results and adjustments made.

9. What is your experience in working with different types of soils and asphalt mixtures?

I have experience working with a variety of soil types, including clay, sand, and gravel. I am also familiar with different asphalt mixtures, such as hot-mix asphalt, warm-mix asphalt, and cold-mix asphalt. I understand the properties of each material and how they affect compaction requirements.

10. Can you describe a challenging road roller operation project you have worked on and how you overcame the challenges?

One challenging project I worked on involved compacting asphalt on a steep slope. The terrain made it difficult to maintain consistent roller stability and achieve uniform compaction. To overcome this, I used a combination of a vibratory roller and a static roller, adjusting the passes and weight distribution to ensure proper compaction and prevent the roller from slipping.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Road Roller Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Road Roller Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Road Roller Operators are responsible for operating heavy machinery to compact and smooth various surfaces, including roads, highways, and construction sites.

1. Equipment Operation

Operate road rollers to compact and smooth asphalt, concrete, and other surfaces.

- Control roller speed, direction, and vibration.

- Adjust roller settings to achieve desired compaction level.

2. Site Preparation

Prepare construction sites by grading, leveling, and compacting the ground.

- Clear debris and obstacles from the site.

- Establish grade and elevation using survey equipment.

3. Quality Control

Monitor compaction results and make adjustments as needed to ensure quality standards are met.

- Use testing equipment to measure compaction density.

- Identify and correct any areas that do not meet specifications.

4. Maintenance and Inspection

Perform routine maintenance and inspections on road rollers to ensure proper operation.

- Lubricate and clean machinery regularly.

- Inspect tires, hydraulic systems, and other components for wear or damage.

Interview Tips

To ace the interview for a Road Roller Operator position, candidates should prepare by understanding the key job responsibilities and following these tips:

1. Highlight Experience and Skills

Emphasize your previous experience operating heavy machinery and your understanding of compaction principles.

- Quantify your accomplishments and provide specific examples of your work.

- Discuss your proficiency in using survey equipment and testing devices.

2. Emphasize Safety and Attention to Detail

Stress your commitment to safety and your meticulous nature when it comes to performing inspections and maintaining equipment.

- Share examples of your adherence to safety protocols.

- Describe your attention to detail and ability to identify and resolve potential issues.

3. Research the Company and Industry

Demonstrate your knowledge of the company and the construction industry by researching their projects and trends.

- Visit the company’s website and read about their recent projects.

- Stay updated on industry news and best practices.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to road construction and compaction techniques.

- Review soil compaction principles and different types of rollers.

- Practice explaining how you troubleshoot and resolve common equipment issues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Road Roller Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!