Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Robot Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

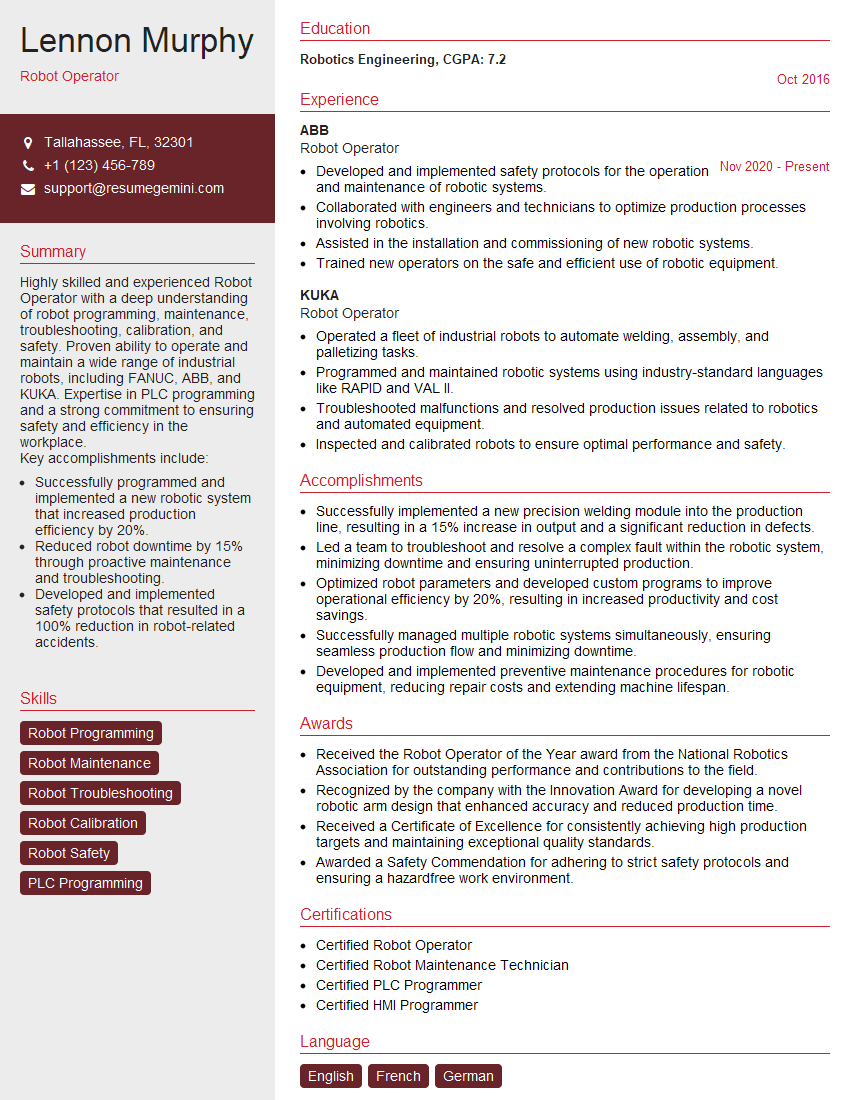

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Robot Operator

1. Describe the key responsibilities of a Robot Operator.

The key responsibilities of a Robot Operator include:

- Operating and monitoring robots in a safe and efficient manner

- Programming and troubleshooting robots

- Maintaining robots and their work environment

- Ensuring that robots are used in accordance with safety regulations

- Working as part of a team to achieve production goals

2. What are the different types of robots that you have experience working with?

Industrial robots

- Articulated robots

- SCARA robots

- Cartesian robots

Collaborative robots

- Cobots

- AGVs

- AMRs

Mobile robots

- Automated guided vehicles (AGVs)

- Autonomous mobile robots (AMRs)

- Drones

3. What are the different programming languages that you are familiar with?

- Robot programming languages (e.g., RAPID, KRL, AML)

- General-purpose programming languages (e.g., Python, Java, C++)

- Machine learning and AI programming languages (e.g., TensorFlow, PyTorch, scikit-learn)

4. What are the different types of sensors that you have experience working with?

- Vision sensors (e.g., cameras, laser scanners)

- Tactile sensors

- Force sensors

- Proximity sensors

- Temperature sensors

5. What are the different types of end-effectors that you have experience working with?

- Grippers

- Welders

- Cutters

- Dispensers

- Cameras

6. What are the different types of safety protocols that you are familiar with?

- ISO 10218-1:2011 Robots and robotic devices – Safety requirements for industrial robots

- ANSI/RIA R15.06-2012 Industrial Robots and Robot Systems – Safety Requirements

- OSHA 29 CFR 1910.212 General requirements for all machines

7. What are the different types of maintenance tasks that you are able to perform?

- Preventive maintenance (e.g., lubrication, cleaning, inspections)

- Corrective maintenance (e.g., repairing or replacing damaged parts)

- Predictive maintenance (e.g., monitoring robot performance and identifying potential problems)

8. What are the different types of troubleshooting techniques that you are familiar with?

- Logical troubleshooting (e.g., using a flowchart to identify the root cause of a problem)

- Empirical troubleshooting (e.g., trying different solutions to see which one works)

- Diagnostic troubleshooting (e.g., using diagnostic tools to identify the source of a problem)

9. What are the different types of quality control procedures that you are familiar with?

- Statistical process control

- Six Sigma

- Lean manufacturing

- ISO 9001

10. What are the different types of documentation that you are able to create and maintain?

- Robot operating procedures

- Maintenance logs

- Troubleshooting guides

- Training materials

- Quality control reports

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Robot Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Robot Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Robot Operators are responsible for the safe and efficient operation of robots in a variety of industrial and manufacturing settings. Some of the most critical responsibilities of Robot Operators include:

1. Robot Programming and Operation

Robot Operators are responsible for programming and operating robots to perform a variety of tasks, such as welding, assembly, and painting. They must be able to understand and follow complex instructions, and be able to troubleshoot and resolve any problems that may arise.

- Program robots using specialized software.

- Operate robots to perform a variety of tasks, such as welding, assembly, and painting.

2. Robot Maintenance and Repair

Robot Operators are also responsible for maintaining and repairing robots. They must be able to identify and resolve mechanical and electrical problems, and be able to replace parts as needed. Preventive maintenance, calibration, and system checks are also important for ensuring optimal performance.

- Inspect robots for wear and tear.

- Perform routine maintenance and repairs.

- Troubleshoot and resolve mechanical and electrical problems.

- Replace parts as needed.

3. Quality Control

Robot Operators are also responsible for ensuring the quality of the products produced by robots. They must be able to inspect products for defects, and be able to make adjustments to the robot’s program or operation to improve quality. Statistical process control (SPC) methods are often used to monitor and improve product quality.

- Inspect products for defects.

- Make adjustments to the robot’s program or operation to improve quality.

- Monitor and improve product quality using statistical process control (SPC) methods.

4. Safety

Robot Operators must always follow safety protocols and procedures. They must be aware of the potential hazards of working with robots, and be able to take steps to avoid accidents. This includes wearing appropriate personal protective equipment (PPE) and following lockout/tagout procedures.

- Follow safety protocols and procedures.

- Be aware of the potential hazards of working with robots.

- Take steps to avoid accidents.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures.

Interview Tips

If you’re preparing for an interview for a Robot Operator position, here are a few tips to help you ace the interview:

1. Research the company

Before you go to your interview, take some time to research the company. This will give you a better understanding of the company’s culture, values, and goals. You’ll also be able to learn more about the specific robot operating systems and technologies used by the company.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people in your network who know about the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked in an interview for a Robot Operator position. These questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with robots?

- What are your salary expectations?

Take some time to practice your answers to these questions so that you can deliver them confidently and clearly in your interview.

3. Be prepared to talk about your experience

In your interview, you’ll be asked about your experience with robots. Be prepared to talk about your experience in detail, including the types of robots you’ve worked with, the tasks you’ve performed, and the results you’ve achieved.

- Use specific examples to illustrate your experience.

- Quantify your results whenever possible.

- Be prepared to talk about your experience with different types of robots.

- Be prepared to talk about your experience with robot programming, maintenance, and repair.

- Be prepared to talk about your experience with quality control and safety.

4. Be enthusiastic

Robot Operators are responsible for operating and maintaining complex machinery. It’s important to be enthusiastic about this type of work in order to be successful. In your interview, be sure to show your passion for robotics and your desire to learn more about the field.

- Talk about your interest in robotics.

- Share your knowledge of the latest developments in robotics.

- Express your desire to learn more about robotics.

5. Ask questions

At the end of your interview, be sure to ask questions about the position and the company. This will show the interviewer that you’re interested in the position and that you’re eager to learn more about the company. Here are a few questions you can ask:

- What are the biggest challenges facing Robot Operators in the company?

- What are the opportunities for advancement in the company?

- What is the company’s culture like?

- What are the company’s plans for the future?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Robot Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.