Are you gearing up for an interview for a Robotics Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Robotics Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

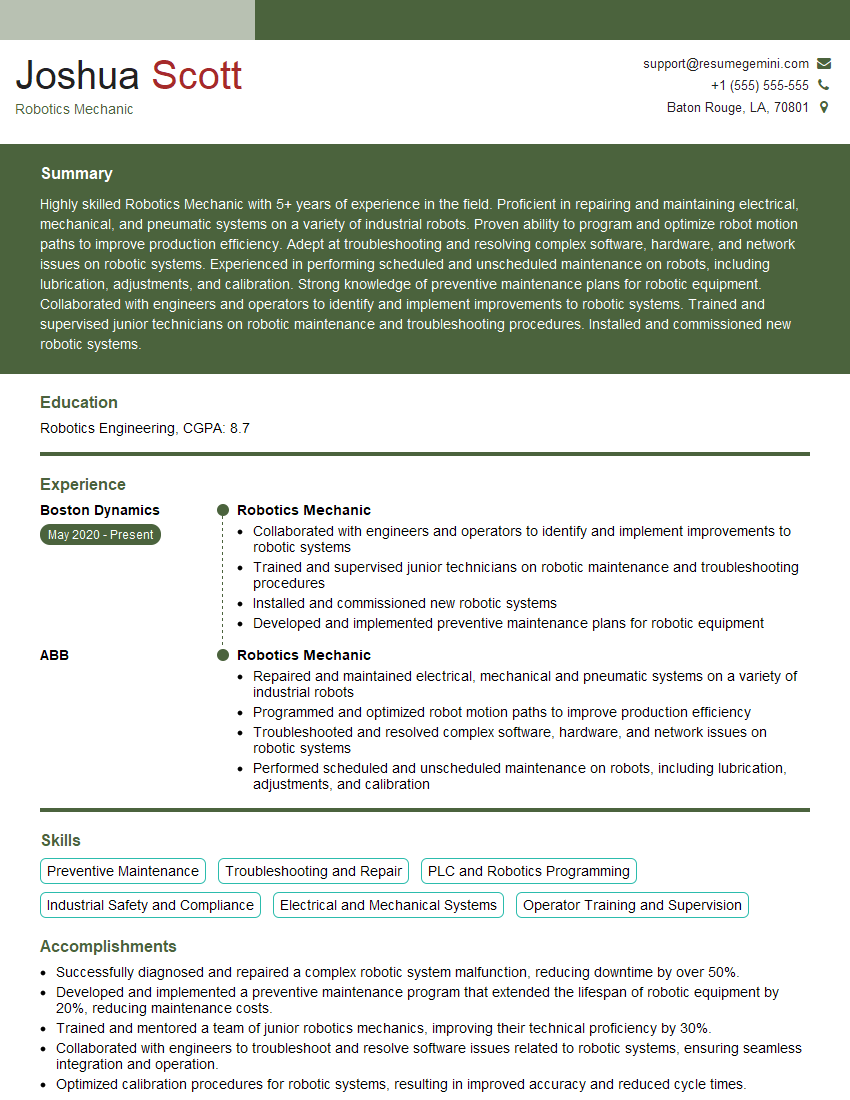

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Robotics Mechanic

1. What are the key components of a robotic system and how do they interact?

- Sensors: Collect data from the environment to provide feedback to the controller.

- Actuators: Convert electrical signals into motion, controlling the robot’s actions.

- Controller: Processes sensor data, makes decisions, and sends commands to actuators.

- Power supply: Provides electrical energy to all components.

- Software: Programs the controller’s behavior, including motion control and decision-making algorithms.

2. Describe the different types of robot manipulators and their applications.

Serial Manipulators

- Jointed arms with multiple degrees of freedom.

- Used for tasks requiring precise positioning and manipulation, such as assembly and welding.

Parallel Manipulators

- Multiple arms connected to a fixed base, providing high stiffness and accuracy.

- Used for tasks requiring high speed and precision, such as pick-and-place operations.

3. Explain the principles of motion control in robotics.

- Position Control: Maintain a desired position with feedback from sensors.

- Velocity Control: Maintain a desired velocity with feedback from sensors.

- Torque Control: Apply a desired torque to an actuator with feedback from sensors.

- Path Planning: Calculate safe and efficient trajectories for the robot to follow.

4. What are the main types of robotic sensors and their uses?

- Vision Sensors: Cameras for object recognition, navigation, and inspection.

- Proximity Sensors: Ultrasonic, infrared, or laser sensors for detecting obstacles and maintaining distances.

- Force Sensors: Measure forces applied to the robot to prevent damage or improve control.

- Inertial Sensors: Accelerometers and gyroscopes for measuring the robot’s motion and orientation.

5. Describe the troubleshooting process for robotic systems.

- Identify the Symptom: Observe the robot’s behavior and identify any abnormal signs.

- Gather Data: Collect data from sensors, logs, and error messages to pinpoint the problem.

- Analyze the Data: Review the collected data to identify potential causes and eliminate non-issues.

- Test Hypotheses: Conduct tests to verify potential causes and isolate the problem.

- Implement a Solution: Repair or replace faulty components, adjust settings, or reprogram the controller to resolve the issue.

6. Explain the concept of robotic path planning and its importance.

- Process of finding a safe and efficient path for the robot to follow in its workspace.

- Protects the robot and its surroundings from collisions or damage.

- Ensures optimal performance by minimizing travel time and energy consumption.

- Algorithms used for path planning include Dijkstra’s algorithm and A* search.

7. Describe the safety precautions you would take while working with industrial robots.

- Wear appropriate safety gear (e.g., gloves, safety glasses).

- Stay clear of the robot’s workspace during operation.

- Use safety gates and interlocks to prevent unauthorized access.

- Perform risk assessments before starting any work.

- Follow established maintenance procedures to keep robots in safe operating condition.

8. What are the challenges in designing and implementing a robotic system for a specific application?

- Identifying customer requirements and translating them into technical specifications.

- Selecting appropriate hardware and software components.

- Designing and integrating complex motion control and sensor systems.

- Ensuring the robot’s safety and reliability in the intended environment.

- Testing and validating the system to meet performance and safety standards.

9. Explain the importance of preventative maintenance for robotic systems.

- Prevents unscheduled downtime and costly repairs.

- Extends the robot’s service life and maintains optimal performance.

- Reduces the risk of accidents and injuries by identifying potential issues early on.

- Involves regular inspections, lubrication, software updates, and calibration.

10. Describe your experience in working with robotic systems and provide examples of projects you have worked on.

- Assembled and tested industrial robots for a manufacturing facility.

- Designed and implemented a robotic welding system for an automotive production line.

- Troubleshooted and repaired a robotic manipulator used in a research laboratory.

- Developed software for a robotic arm used in a surgical setting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Robotics Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Robotics Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A robotics mechanic is a highly skilled technician responsible for the installation, maintenance, repair, troubleshooting, and programming of robotic systems and equipment.

1. Installation and Assembly

Assemble robotic systems from individual components, following blueprints and schematics

- Ensure proper alignment, calibration, and functionality of all components

- Install safety systems and safeguards

2. Maintenance and Repair

Perform regular maintenance to ensure optimal performance and prevent breakdowns

- Inspect, clean, lubricate, and adjust components

- Identify and repair mechanical, electrical, and software malfunctions

3. Troubleshooting and Diagnostics

Use diagnostic tools and techniques to identify the root cause of system failures

- Analyze error codes and data from sensors and actuators

- Determine the appropriate repair or replacement actions

4. Programming and Software Updates

Program robotic systems using proprietary software and languages

- Create, modify, and optimize software routines

- Perform software updates and patches

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a robotics mechanic position:

1. Research the Company and Position

Familiarize yourself with the company’s values, mission, products/services, and the specific requirements of the robotics mechanic role.

- Visit the company’s website and LinkedIn page

- Read industry news and articles related to robotics

2. Highlight Your Skills and Experience

Emphasize your technical skills and experience in the key areas of robotics mechanics: installation, maintenance, repair, troubleshooting, and programming.

- Quantify your accomplishments and provide specific examples

- Use strong action verbs and industry-specific terminology

3. Prepare for Technical Questions

Expect to be asked technical questions about robotics systems, components, and troubleshooting techniques.

- Review common interview questions and practice answering them

- Be prepared to discuss your knowledge of robotics principles and industry standards

4. Ask Relevant Questions

Asking well-thought-out questions at the end of the interview demonstrates your interest and engagement.

- Ask about the specific projects or responsibilities you will be involved in

- Inquire about the company’s commitment to robotics innovation and development

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Robotics Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!