Feeling lost in a sea of interview questions? Landed that dream interview for Rock Crushing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rock Crushing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

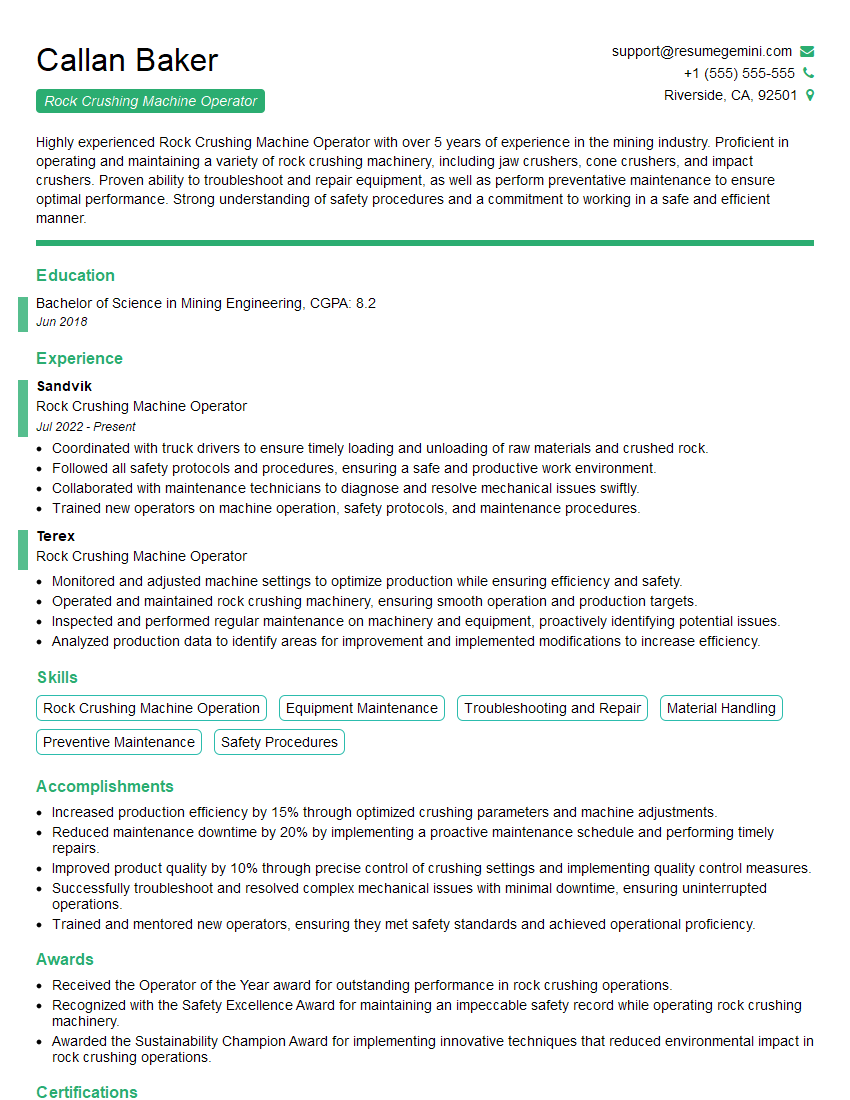

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rock Crushing Machine Operator

1. What are the key components of a rock crushing machine and how do they interact?

- Jaw Crusher: This is the primary crushing stage, where large rocks are broken down into smaller pieces.

- Cone Crusher: This is the secondary crushing stage, where the smaller pieces from the jaw crusher are further reduced in size.

- Vibrating Screen: This separates the crushed rock into different sizes, allowing for the production of specific grades.

- Conveyor Belt: This transports the crushed rock from one stage to another and to the final storage or loading area.

2. Describe the different types of rock crushing machines and their applications.

Jaw Crushers

- Used for primary crushing of large rocks.

- Have a fixed jaw and a movable jaw that create a crushing action.

Cone Crushers

- Used for secondary and tertiary crushing to produce smaller sizes.

- Have a conical crushing chamber with a rotating cone that crushes the rock against a fixed mantle.

Impact Crushers

- Used for producing fine aggregates and sand.

- Utilize high-speed rotating hammers or impellers to shatter rocks.

3. How do you identify and troubleshoot common problems that occur in rock crushing machines?

- Blockages: Inspect the machine for jammed rocks and clear them using appropriate tools.

- Overheating: Check for lubrication issues, bearing failures, and excessive wear.

- Uneven Crushing: Adjust the settings of the crushing chamber or replace worn components.

- Excessive Vibration: Inspect the machine for loose bolts, misalignment, or unbalanced rotors.

4. What safety precautions should be taken when operating a rock crushing machine?

- Wear appropriate personal protective equipment (PPE), including hard hat, safety glasses, and earplugs.

- Ensure all guards and safety devices are in place and functioning properly.

- Keep a safe distance from moving parts and avoid contact with the crushed rock.

- Follow established operating procedures and lockout/tagout protocols.

5. What maintenance tasks are essential for the smooth operation of a rock crushing machine?

- Regular Lubrication: Grease and oil all moving parts to minimize wear and tear.

- Inspection and Adjustment: Check for wear, damage, or misalignment and make necessary adjustments.

- Screen Replacement: Replace worn or damaged screens to ensure proper size separation.

- Conveyor Belt Maintenance: Inspect and replace worn or damaged belts to prevent downtime.

6. How do you optimize the performance of a rock crushing machine to increase efficiency and productivity?

- Fine-tune Settings: Adjust crushing chamber settings to optimize particle size and minimize waste.

- Proper Feed Rate: Ensure a consistent and appropriate feed rate to prevent overloads or underutilization.

- Regular Maintenance: Follow recommended maintenance schedules to keep the machine in optimal condition.

- Operator Training: Ensure operators are well-trained to operate the machine efficiently and safely.

7. What strategies can be employed to reduce downtime and improve the availability of a rock crushing machine?

- Preventive Maintenance: Implement a regular maintenance program to identify and address potential issues before they cause downtime.

- Spare Parts Inventory: Maintain a stock of critical spare parts to minimize waiting time for replacements.

- Redundancy: Consider installing redundant components, such as backup conveyors or crushers, to mitigate the impact of single-point failures.

- Operator Training: Train operators on proper operating techniques to avoid misuse and extend machine life.

8. Explain the importance of calibrated instruments and how they contribute to the accuracy and efficiency of a rock crushing machine.

- Accurate Crushing Settings: Calibrated instruments ensure that crushing chamber settings are precise, resulting in consistent particle size.

- Optimized Production: Calibrated instruments help maintain the desired feed rate, preventing overloads or underutilization.

- Improved Product Quality: Accurate measurements and controls allow for consistent production of crushed rock that meets specifications.

9. How do you handle unexpected situations or emergencies that may arise during the operation of a rock crushing machine?

- Safety First: Prioritize the safety of personnel and equipment.

- Problem Identification: Quickly identify the cause of the emergency and assess the severity.

- Response Plan: Implement appropriate emergency protocols, such as machine shutdown, isolation, and evacuation.

- Communication: Inform supervisors, maintenance teams, and other affected parties.

10. Describe your experience with different types of rock crushing machines and how it has prepared you for this role.

- Jaw Crushers: Operated and maintained jaw crushers in a quarry setting, ensuring efficient primary crushing.

- Cone Crushers: Assisted in the installation and calibration of cone crushers, optimizing secondary and tertiary crushing processes.

- Impact Crushers: Participated in the troubleshooting and repair of impact crushers, maximizing fine aggregate production.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rock Crushing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rock Crushing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rock Crushing Machine Operators play a crucial role in the mining and construction industries, operating heavy machinery to extract and process raw materials. Their responsibilities include:

1. Machine Operation

Operate rock crushing machines to break down large rocks into smaller aggregates used in construction materials and other applications.

- Monitor machine settings and adjust as needed to optimize performance.

- Troubleshoot and resolve minor issues with the equipment.

2. Production Monitoring

Monitor production levels and ensure the machine is operating efficiently and meeting targets.

- Record production data and report any deviations from expected outputs.

- Identify areas for improvement and suggest modifications to enhance productivity.

3. Maintenance and Inspections

Perform routine maintenance and inspections on the crushing machine, including lubrication, cleaning, and replacement of worn parts.

- Follow established safety procedures and maintain a clean and organized work area.

- Report any major issues or maintenance requirements to supervisors promptly.

4. Safety Compliance

Adhere to all safety regulations and guidelines, wearing appropriate protective gear and following established protocols.

- Identify and assess potential hazards in the work environment.

- Operate equipment responsibly and avoid unsafe practices.

Interview Tips

To prepare for an interview as a Rock Crushing Machine Operator, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the mining or construction company you’re applying to, as well as the industry as a whole. This will demonstrate your interest and understanding of the role.

2. Highlight Your Experience and Skills

Emphasize your previous experience operating rock crushing machines and any relevant skills or certifications you have obtained. Quantify your accomplishments whenever possible, using specific examples.

3. Prepare Answers to Common Interview Questions

Some common interview questions you may encounter include:

- Tell us about your experience operating rock crushing machines.

- Describe a time when you successfully resolved a problem with a machine.

- How do you ensure safety when working with heavy machinery?

4. Be Prepared for Technical Questions

You may be asked technical questions about the operation and maintenance of rock crushing machines. Review the specifications and operating principles of the equipment you have experience with.

5. Practice Your Answers and Seek Feedback

Rehearse your answers to common interview questions and seek feedback from a friend, family member, or career counselor. This will help you refine your responses and build confidence.

6. Dress Professionally and Arrive Punctually

Make a good impression by dressing professionally and arriving at the interview on time. This shows respect for the interviewer and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rock Crushing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.