Are you gearing up for an interview for a Rocket Propellant Plant Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rocket Propellant Plant Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

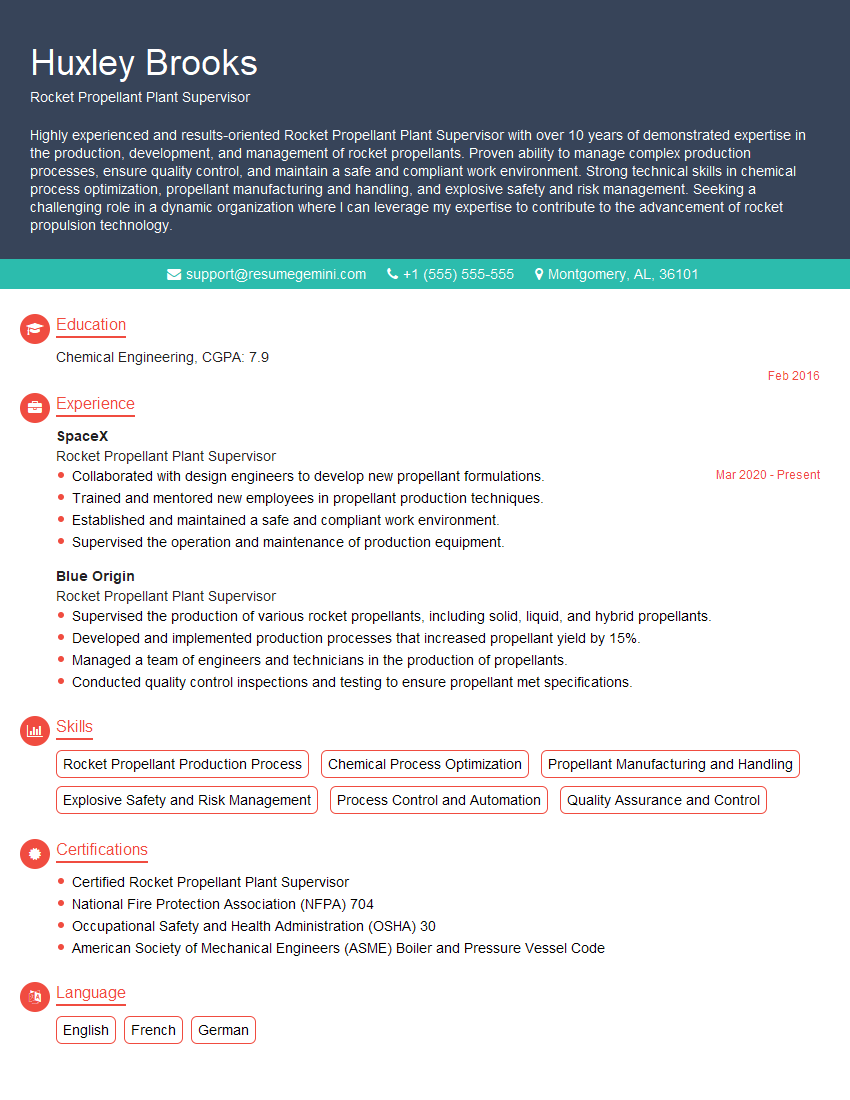

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rocket Propellant Plant Supervisor

1. Explain the different types of rocket propellants and their properties?

Rocket propellants are categorized into three types based on their physical states: solid, liquid, and gaseous. Each type has unique properties that influence their performance and applications.

- Solid propellants: Composed of a mixture of fuel and oxidizer in a solid form, providing high thrust and specific impulse. They are reliable, easy to store, and have a long shelf life. Examples include ammonium perchlorate composite propellants (APCP) and hydroxyl-terminated polybutadiene (HTPB).

- Liquid propellants: Stored in separate tanks as fuel and oxidizer and mixed before combustion. They offer greater control over thrust and specific impulse by adjusting the mixture ratio. Liquid oxygen (LOX) and kerosene (RP-1) are common examples.

- Gaseous propellants: Stored as gases and can be used as monopropellants (single-component) or bipropellants (two-component). They provide high specific impulse and throttleability, but have lower density and require pressurization for storage.

2. Describe the key safety considerations in handling and storing rocket propellants?

General Safety Measures

- Adherence to strict safety protocols and regulations

- Proper handling and storage procedures

- Use of personal protective equipment (PPE)

- Regular training and certification for personnel

Specific Considerations for Different Propellant Types

- Solid propellants: Sensitive to shock and heat, requiring careful handling and storage

- Liquid propellants: Flammable and toxic, necessitating proper ventilation and handling

- Gaseous propellants: High pressures, requiring leak-proof storage and handling systems

3. Explain the process of quality control in the manufacturing of rocket propellants?

Quality control in rocket propellant manufacturing involves rigorous testing and inspection throughout the production process. Here are key steps:

- Raw material inspection: Incoming materials are tested for purity, composition, and compliance with specifications.

- In-process testing: During production, samples are taken at various stages to ensure adherence to process parameters and product specifications.

- Final product testing: Completed propellants undergo comprehensive testing, including performance evaluations, stability assessments, and safety checks, to verify product quality and compliance.

- Documentation and traceability: Detailed records are maintained for all aspects of production, allowing for traceability and accountability.

4. Discuss the role of automation in modern rocket propellant plants?

- Improved efficiency: Automation reduces manual labor, increases production speed, and enhances overall plant efficiency.

- Enhanced safety: Automated systems minimize human exposure to hazardous propellants, reducing the risk of accidents.

- Increased accuracy: Automation ensures precise control over process parameters, resulting in consistent and high-quality propellants.

- Data collection and analysis: Automated systems collect real-time data, enabling continuous monitoring and data analysis to optimize plant operations.

- Reduced operating costs: Automation can reduce labor requirements and energy consumption, leading to lower operating costs.

5. What are the key performance indicators (KPIs) used to evaluate the effectiveness of a rocket propellant plant?

- Production output: Total quantity of propellant produced within a specified period.

- Propellant quality: Compliance with performance and safety specifications, as determined through testing and certification.

- Plant efficiency: Ratio of actual production to theoretical capacity, indicating resource utilization and optimization.

- Safety record: Number and severity of accidents or incidents, reflecting the effectiveness of safety measures and protocols.

- Cost of production: Total expenses incurred in producing a given quantity of propellant, including raw materials, labor, and overhead.

- Customer satisfaction: Feedback and metrics related to product quality, delivery times, and technical support.

6. How do you ensure continuous improvement in the efficiency of a rocket propellant plant?

- Regular process reviews: Conduct thorough assessments to identify areas for improvement and streamline operations.

- Technology adoption: Explore and implement new technologies to enhance automation, data analysis, and equipment efficiency.

- Employee empowerment: Encourage and support employees to suggest ideas and implement innovative solutions to optimize processes.

- Benchmarking and best practices: Study industry standards and best practices to incorporate proven techniques and strategies into the plant’s operations.

- Data-driven decision-making: Utilize collected data to analyze trends, identify bottlenecks, and make informed decisions to improve efficiency.

7. Describe your experience in managing a team of engineers and technicians in a rocket propellant plant?

Leadership and Management

- Provided clear direction and motivation to team members

- Established a positive and collaborative work environment

- Delegated tasks effectively and monitored progress

Technical Expertise

- Guided engineers in designing and implementing process improvements

- Collaborated with technicians to troubleshoot equipment issues and ensure smooth operations

- Ensured compliance with safety protocols and industry standards

8. What strategies would you implement to mitigate environmental impact during propellant production?

- Emissions control: Install scrubbers and other pollution control devices to reduce air emissions.

- Waste management: Implement proper disposal and recycling programs for hazardous waste and spent propellants.

- Energy conservation: Optimize energy consumption through efficient equipment and process improvements.

- Water conservation: Implement water-saving measures, such as rainwater harvesting and closed-loop systems.

- Environmental monitoring: Regularly monitor environmental parameters and conduct environmental impact assessments to identify and minimize potential risks.

9. How do you handle emergency situations involving propellant spills or leaks?

Immediate Actions

- Activate emergency response protocol

- Secure the area and evacuate personnel

- Contain the spill or leak to prevent spread

Investigation and Reporting

- Conduct a thorough investigation to determine the cause

- Prepare and submit detailed incident reports to relevant authorities

- Implement corrective actions to prevent similar incidents in the future

10. What is your understanding of the latest advancements in rocket propellant technology?

- Advanced solid propellants: Development of high-energy and low-emission solid propellants using nano-additives and advanced composite materials.

- Liquid propellant blends: Exploration of innovative fuel and oxidizer combinations to achieve higher performance and reduce toxicity.

- Gelled propellants: Development of semi-solid propellants that offer improved stability and handling characteristics.

- Additive manufacturing (3D printing): Application of 3D printing to create complex propellant geometries and customized designs.

- Green propellants: Development of environmentally friendly propellants with reduced toxicity and emissions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rocket Propellant Plant Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rocket Propellant Plant Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rocket Propellant Plant Supervisors are responsible for the safe and efficient operation of rocket propellant production facilities. They oversee all aspects of production, from raw material procurement to finished product storage. Key responsibilities include:

1. Production Management

Supervise and coordinate production activities to ensure that propellant is produced according to specifications and within established timelines.

- Develop and implement production plans.

- Monitor production processes and make adjustments as needed.

2. Quality Control

Ensure that all propellant products meet or exceed quality standards. Implement and maintain quality control procedures.

- Conduct inspections and tests to verify product quality.

- Investigate and resolve quality issues.

3. Safety Management

Ensure that all operations are conducted in a safe manner. Develop and implement safety procedures and protocols.

- Conduct safety audits and inspections.

- Train and supervise employees on safety procedures.

4. Equipment Maintenance

Oversee the maintenance and repair of all production equipment. Ensure that equipment is operating efficiently and safely.

- Schedule and coordinate maintenance activities.

- Monitor equipment performance and identify potential issues.

5. Environmental Management

Comply with all environmental regulations and standards. Minimize the environmental impact of production activities.

- Develop and implement environmental management plans.

- Monitor environmental performance and report on compliance.

Interview Tips

To ace your interview for a Rocket Propellant Plant Supervisor position, follow these tips:

1. Research the Company and Position

Thoroughly research the company and the specific position you are applying for. This will allow you to answer questions intelligently and demonstrate your knowledge of the industry.

2. Prepare for Technical Questions

Be prepared to answer technical questions about rocket propellant production and safety. Review the job description and prepare examples of your experience that demonstrate your skills.

3. Practice Your STAR Method

Use the STAR method (Situation, Task, Action, Result) to answer behavioral interview questions. This will help you provide clear and concise answers that highlight your accomplishments.

4. Highlight Your Safety Experience

Emphasize your experience in safety management and compliance. This is a critical aspect of the role of a Rocket Propellant Plant Supervisor.

5. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Be enthusiastic and positive throughout the interview process. This will make a great impression on the hiring manager.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rocket Propellant Plant Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.