Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rod and Tube Straightener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

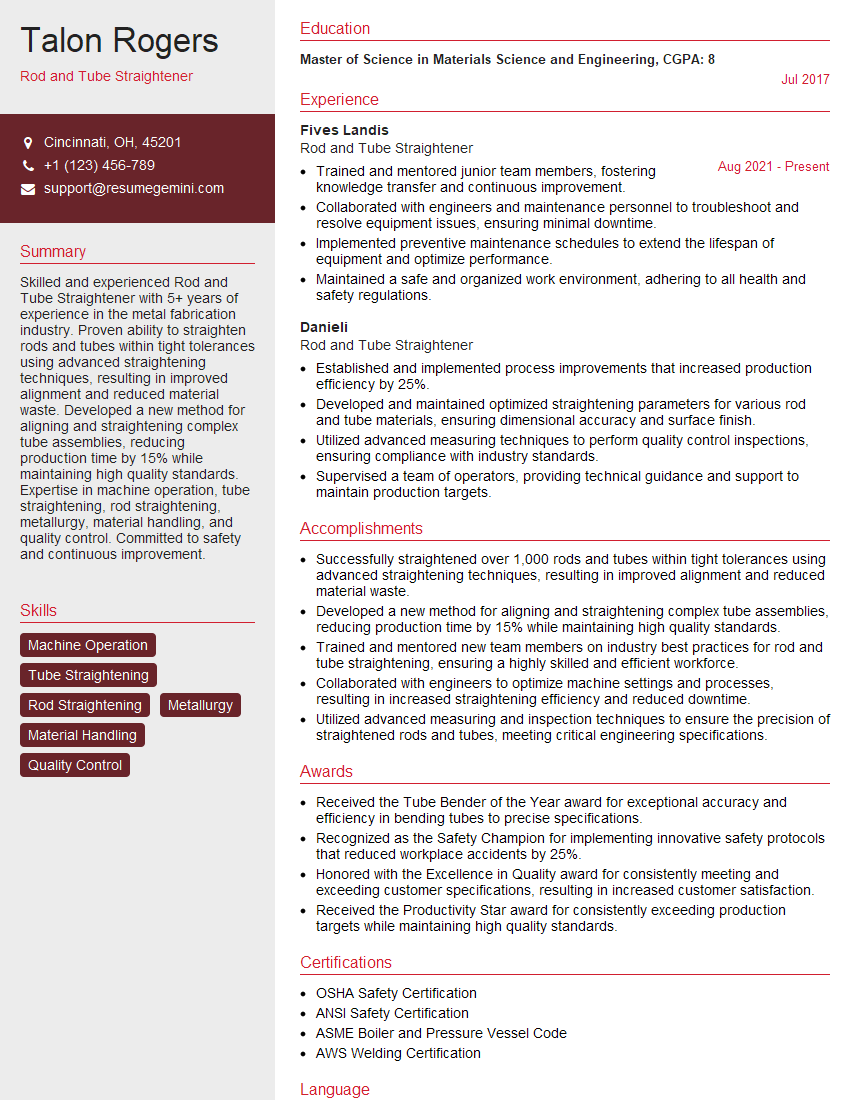

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rod and Tube Straightener

1. Explain the process of straightening a bent rod using a rod straightener machine?

The process of straightening a bent rod using a rod straightener machine involves the following steps:

- Loading the Machine: The bent rod is loaded onto the infeed conveyor of the straightening machine.

- Entering the Straightener: The rod enters the straightening section of the machine, which consists of a series of driven and idler rolls.

- Straightening Operation: As the rod passes through the rolls, it undergoes a combination of bending and tensioning forces that gradually straighten it.

- Adjustment of Parameters: The speed and pressure of the rolls can be adjusted to optimize the straightening process for different rod diameters and materials.

- Unloading the Machine: Once the rod is straightened, it is unloaded onto the outfeed conveyor.

2. How do you ensure the accuracy of the straightened rods?

Maintaining Machine Calibration

- Regularly calibrate the straightening machine to ensure its accuracy.

- Use precision measuring instruments to verify the straightness of the rods.

Monitoring Roll Condition

- Inspect the straightening rolls for wear and damage.

- Replace or recondition worn rolls to maintain optimal performance.

Optimizing Process Parameters

- Fine-tune the speed and pressure of the rolls based on the rod material and diameter.

- Use appropriate lubricants to reduce friction and improve accuracy.

3. What types of rods can be straightened using the rod straightener machine?

The rod straightener machine can be used to straighten various types of rods, including:

- Round rods

- Square rods

- Rectangular rods

- Hexagonal rods

- Oval rods

The machine’s capabilities depend on the specific model and its design specifications.

4. What are the common causes of rod bending during the straightening process?

- Improper Roll Alignment: Misaligned rolls can cause uneven bending and twisting of the rod.

- Excessive Roll Pressure: Applying too much pressure to the rolls can overstress the rod and lead to bending.

- Damaged or Worn Rolls: Worn or damaged rolls can create irregularities on the rod surface, resulting in bending.

- Insufficient Lubrication: Lack of lubrication can increase friction and cause the rod to stick to the rolls, leading to bending.

- Material Defects: Inherent defects in the rod material, such as inclusions or voids, can weaken the rod and make it susceptible to bending.

5. How do you troubleshoot and resolve rod bending issues?

- Check Roll Alignment: Ensure that the straightening rolls are properly aligned and adjusted.

- Adjust Roll Pressure: Optimize the roll pressure to minimize bending while maintaining adequate straightening force.

- Inspect Rolls for Damage: Examine the rolls for any damage or wear that could be causing irregularities.

- Apply Lubrication: Ensure that the machine is properly lubricated to reduce friction and prevent sticking.

- Examine Rod Material: Inspect the incoming rod material for any defects or inconsistencies that may contribute to bending.

6. Describe the maintenance procedures for a tube straightener machine?

- Regular Cleaning: Clean the machine regularly to remove dirt, dust, and debris.

- Roll Inspection and Maintenance: Inspect the straightening rolls and replace or recondition them as needed to maintain accuracy and performance.

- Lubrication: Ensure that the machine is properly lubricated according to the manufacturer’s recommendations.

- Tension Adjustment: Check and adjust the tension settings to optimize the straightening process.

- Electrical System Checks: Inspect the electrical components, wiring, and connections to ensure proper operation.

7. How do you handle emergency situations while operating a tube straightener machine?

- Immediate Shutdown: In case of any emergency, immediately shut down the machine to prevent further damage.

- Identify the Problem: Quickly assess the situation and identify the cause of the emergency.

- Safety First: Ensure the safety of yourself and others by following proper safety procedures.

- Contact Supervisor: Inform your supervisor about the emergency and request assistance if needed.

- Troubleshooting: Attempt to troubleshoot the problem using the recommended procedures if possible.

8. What are the differences between a 2-roll and a 4-roll tube straightener machine?

2-Roll Straightener

- Consists of two driven rolls that bend and tension the tube.

- Suitable for smaller diameter tubes

- Provides less precise straightening compared to 4-roll machines.

4-Roll Straightener

- Utilizes four rolls, two driven and two idler rolls.

- Can handle larger diameter tubes

- Provides higher precision and accuracy in straightening.

- More complex and expensive than 2-roll machines.

9. How do you achieve the desired straightness tolerance for a given tube?

- Proper Machine Setup: Ensure that the tube straightener is properly calibrated and adjusted.

- Appropriate Roll Settings: Select the correct roll configuration and apply the optimal pressure to achieve the desired straightness.

- Material Considerations: Take into account the material properties and diameter of the tube.

- In-Process Monitoring: Monitor the straightening process and make adjustments as needed to maintain accuracy.

- Post-Process Inspection: Utilize precision measuring instruments to verify that the straightened tubes meet the specified tolerance.

10. Describe the importance of preventive maintenance for a tube straightener machine?

- Extend Machine Life: Regular maintenance helps prolong the lifespan of the machine and its components.

- Improved Performance: Proper maintenance ensures optimal performance and accuracy of the straightening process.

- Reduced Downtime: Preventive maintenance reduces the likelihood of breakdowns and unplanned downtime.

- Increased Safety: Regular maintenance minimizes the risk of accidents or injuries due to malfunctioning equipment.

- Lower Operating Costs: By preventing major repairs and replacements, preventive maintenance can save on overall operating costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rod and Tube Straightener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rod and Tube Straightener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rod and Tube Straighteners are responsible for operating and maintaining rod and tube straightening machines to ensure that the rods and tubes meet the required specifications. They may also perform other duties, such as inspecting the rods and tubes for defects, making adjustments to the machines, and keeping records of the production process.

1. Operate and Maintain Rod and Tube Straightening Machines

Rod and Tube Straighteners must be able to operate and maintain rod and tube straightening machines efficiently and safely. They must be able to identify and correct any problems that arise, and they must be able to make adjustments to the machines to ensure that the rods and tubes meet the required specifications.

- Follow established operating procedures and safety guidelines

- Calibrate and adjust machines to meet production specifications

- Monitor machine performance and identify potential issues

- Perform routine maintenance, including lubrication and cleaning

2. Inspect Rods and Tubes for Defects

Rod and Tube Straighteners must be able to inspect rods and tubes for defects. They must be able to identify and remove any defects that could affect the quality of the product.

- Visually inspect rods and tubes for surface imperfections, cracks, and other defects

- Use specialized equipment to detect internal flaws and defects

- Classify defects according to established standards

3. Make Adjustments to Machines

Rod and Tube Straighteners must be able to make adjustments to machines to ensure that the rods and tubes meet the required specifications. They must be able to identify and correct any problems that arise, and they must be able to make adjustments to the machines to ensure that the rods and tubes meet the required specifications.

- Adjust machine settings to achieve desired product dimensions and tolerances

- Troubleshoot and resolve machine malfunctions

- Recommend and implement improvements to machine processes

4. Keep Records of the Production Process

Rod and Tube Straighteners must be able to keep records of the production process. They must be able to record the number of rods and tubes that are produced, the specifications of the rods and tubes, and any problems that arise during the production process.

- Maintain detailed production logs and records

- Document product specifications, production quantities, and quality control checks

- Generate reports on production efficiency and quality indicators

Interview Tips

To ace your interview for a Rod and Tube Straightener position, it is important to be well-prepared. Here are a few tips to help you prepare:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website and social media pages, and you can learn more about the position by reading the job description.

- Visit the company’s website and social media pages

- Read the job description carefully

- Research the industry and the company’s competitors

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Prepare answers to common interview questions

- Practice your answers out loud

- Get feedback from a friend or family member

3. Prepare questions to ask the interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”

- Research the company and the industry

- Brainstorm questions that show your interest and knowledge

- Practice asking your questions confidently

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Choose appropriate business attire

- Arrive on time for your interview

- Make eye contact and smile when you greet the interviewer

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rod and Tube Straightener interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.