Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roll Form Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

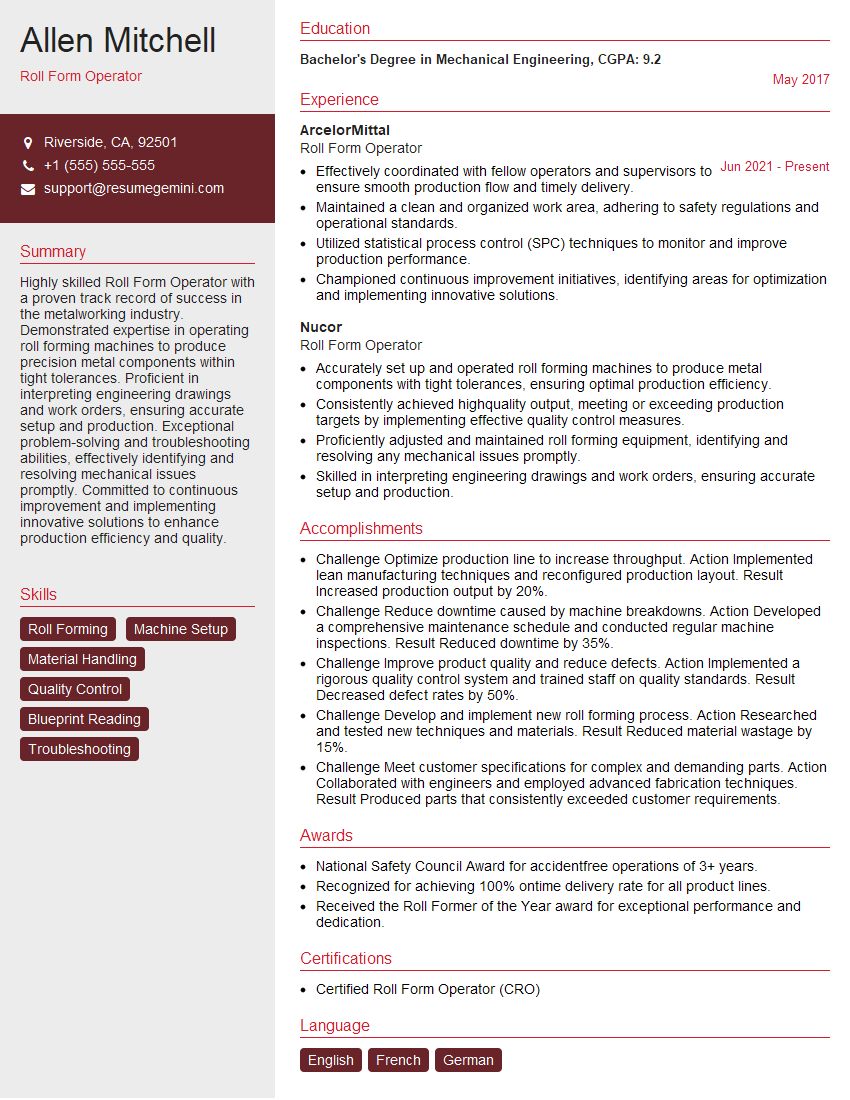

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Form Operator

1. How do you ensure that the roll forming machine is properly set up and calibrated?

To ensure proper setup and calibration of the roll forming machine, I follow a comprehensive procedure:

- Verify machine specifications: I cross-reference the machine’s specifications with the required product dimensions.

- Check alignment and clearances: I carefully adjust the rolls, guides, and other components to achieve the desired dimensions and tolerances.

- Calibrate forming rolls: Using appropriate gauges and measuring tools, I calibrate the rolls to ensure they are positioned accurately.

- Set up feed and exit systems: I configure the material feed and exit systems to handle the specific material and profile being produced.

- Test run and adjustments: I conduct test runs and make necessary fine adjustments to optimize machine performance and meet quality standards.

2. Describe your experience in troubleshooting and resolving roll forming defects.

Identifying Defects:

- Dimensional inaccuracies: I analyze the formed product’s dimensions and compare them to specifications.

- Surface imperfections: I inspect the surface of the product for scratches, dents, or other defects.

- Material damage: I examine the material for tears, cracks, or other damage that may affect the product’s integrity.

Problem Solving:

- Roll alignment: I check the alignment of the forming rolls to identify any deviations.

- Material tension: I adjust the material tension to ensure it is taut enough to form properly.

- Machine settings: I verify the machine’s settings, such as speed and temperature, to ensure they are optimal.

- Maintenance: I inspect the machine for any worn or damaged components that may need replacement or repair.

3. How do you maintain and perform preventive maintenance on roll forming machines?

- Regular cleaning: I clean the machine regularly to remove metal shavings, dust, and other debris that can affect performance.

- Lubrication: I follow a lubrication schedule to ensure all moving parts are properly lubricated.

- Component inspection: I inspect forming rolls, guides, and other components for wear or damage and replace them as needed.

- Safety checks: I perform safety checks to ensure all guards and safety features are in place and functioning correctly.

- Record keeping: I maintain a maintenance log to document all maintenance activities and any issues encountered.

4. Can you explain the different types of roll forming processes and their applications?

- Cold roll forming: This process involves forming metal at room temperature, typically used for thin and delicate materials.

- Hot roll forming: Metal is heated before forming, allowing for more complex shapes and increased strength.

- Hydroforming: A combination of cold forming and hydroforming, where a high-pressure fluid is used to force the metal into shape.

- Roll bending: Uses rollers to bend metal sheets into cylindrical or curved shapes.

- Seaming: A specialized roll forming process that joins two pieces of metal together by interlocking them.

5. How do you ensure that formed products meet customer specifications and quality standards?

To ensure product quality, I adhere to the following measures:

- Quality inspections: I conduct regular inspections during production to identify any deviations from specifications.

- Dimensional checks: I use precision measuring tools to verify that the product’s dimensions meet customer requirements.

- Material verification: I check that the material used matches the specified grade and thickness.

- Surface inspection: I examine the product’s surface for any defects that could affect its performance or appearance.

- Documentation: I maintain detailed records of all inspection results to provide traceability and ensure compliance.

6. What are the safety precautions that you observe when operating roll forming machines?

- Proper training: I am fully trained and certified to operate the roll forming machine safely.

- Wear protective gear: I always wear appropriate personal protective equipment, including gloves, safety glasses, and hearing protection.

- Machine guarding: I ensure that all guards and safety features are in place and functioning properly.

- Lockout/tagout procedures: I follow established lockout/tagout procedures when performing maintenance or repairs.

- Safe handling: I handle materials carefully to prevent injuries from sharp edges or heavy loads.

7. How do you measure and adjust the tension of the material being formed?

- Tension gauge: I use a tension gauge to measure the tension of the material at different points during the forming process.

- Visual inspection: I observe the material’s behavior as it passes through the rolls to assess its tension.

- Adjustments: I adjust the tension by modifying the settings of the feed and exit systems, such as speed and feed rate.

8. Can you describe your experience in operating different types of roll forming machines?

I have experience operating various types of roll forming machines, including:

- Two-high reversing mill: Used for forming heavy-duty structural shapes.

- Four-high mill: For high-speed production of thin and wide materials.

- Cluster mill: Capable of forming complex shapes with multiple passes.

- Tube and pipe mill: Specialized for producing seamless tubes and pipes.

9. How do you handle and prevent material waste during roll forming operations?

To minimize waste, I employ the following strategies:

- Optimized nesting: I arrange the material layout to maximize the yield and minimize scrap.

- Proper lubrication: Lubricating the rolls and guides reduces friction and prevents material from sticking, reducing waste.

- Accurate setup: Precise machine setup ensures that the material is properly aligned and formed, minimizing defects and waste.

- Reuse and recycling: I collect and recycle scrap material whenever possible, reducing environmental impact and waste.

10. Can you explain the principles of roll pass design and how it affects the final formed product?

Roll pass design involves the geometry and arrangement of the grooves in the forming rolls:

- Material flow: The shape and depth of the grooves determine the material’s flow and the final product’s shape.

- Progressive deformation: Multiple passes through the rolls with gradually changing groove shapes gradually transform the material into the desired shape.

- Surface finish: The roll surface finish influences the surface quality of the formed product.

- Product accuracy: Precise roll pass design ensures accurate dimensions and tolerances in the final product.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Form Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Form Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roll Form Operators are accountable for the operation and monitoring of roll forming machines, ensuring the production of metal components and products of high quality and within specifications. They play a crucial role in maintaining the efficiency and accuracy of the production line, adhering to safety regulations, and contributing to the overall success of the manufacturing process

1. Machine Operation and Monitoring

Operate roll forming machines skillfully, ensuring smooth and efficient production.

- Set up and adjust machine parameters, such as speed, feed rate, and tension, to achieve optimal performance and product quality.

- Monitor machine performance, identifying and promptly addressing any issues or malfunctions to prevent costly downtime.

- Inspect raw materials and finished products, verifying dimensions and quality against specifications.

2. Quality Assurance

Maintain high product quality standards by adhering to specified tolerances and specifications.

- Conduct regular inspections of finished products, utilizing measuring tools and instruments to ensure adherence to required dimensions and tolerances.

- Identify and resolve quality issues promptly, taking corrective actions to prevent recurrence.

- Maintain accurate records of production, quality checks, and machine performance for traceability and continuous improvement.

3. Machine Maintenance

Perform basic maintenance tasks to ensure the longevity and optimal performance of roll forming machines.

- Clean and lubricate machines regularly to minimize wear and tear.

- Replace worn or damaged parts, such as rollers and dies, to maintain machine efficiency and product quality.

- Report any maintenance issues or major repairs to supervisors for timely intervention.

4. Safety and Compliance

Prioritize safety and compliance with all applicable regulations, ensuring a safe working environment.

- Follow established safety protocols and wear appropriate personal protective equipment.

- Maintain a clean and organized work area to minimize hazards and promote efficiency.

- Stay informed about industry best practices and regulatory updates to ensure compliance.

Interview Tips

To prepare effectively for a Roll Form Operator interview, consider the following tips

1. Research the Company and Industry

Gather information about the company’s history, products, and industry standing. This knowledge demonstrates your interest and enthusiasm for the opportunity and allows you to ask insightful questions during the interview.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay updated on trends and best practices.

2. Practice Common Interview Questions

Prepare for commonly asked interview questions related to roll forming operations, quality control, and safety procedures. Practice answering these questions concisely and effectively to showcase your skills and experience.

- Describe your experience operating and monitoring roll forming machines.

- How do you ensure the quality of finished products meets specifications?

- Explain your approach to maintaining and troubleshooting roll forming machines.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments and provide specific examples to demonstrate your capabilities.

- Highlight your proficiency in operating different types of roll forming machines.

- Share examples of how you have improved product quality or efficiency in previous roles.

- Describe your experience in adhering to safety protocols and maintaining a safe work environment.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer shows your engagement and interest in the opportunity. Ask questions about the company’s culture, growth prospects, and any specific challenges or projects related to the role.

- What are the company’s goals for the roll forming department in the coming year?

- What opportunities are there for professional development and advancement?

- Can you describe the typical day-to-day responsibilities of a Roll Form Operator in this role?

Next Step:

Now that you’re armed with the knowledge of Roll Form Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Roll Form Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini