Are you gearing up for a career in Roll Forming Machine Set-Up Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Roll Forming Machine Set-Up Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

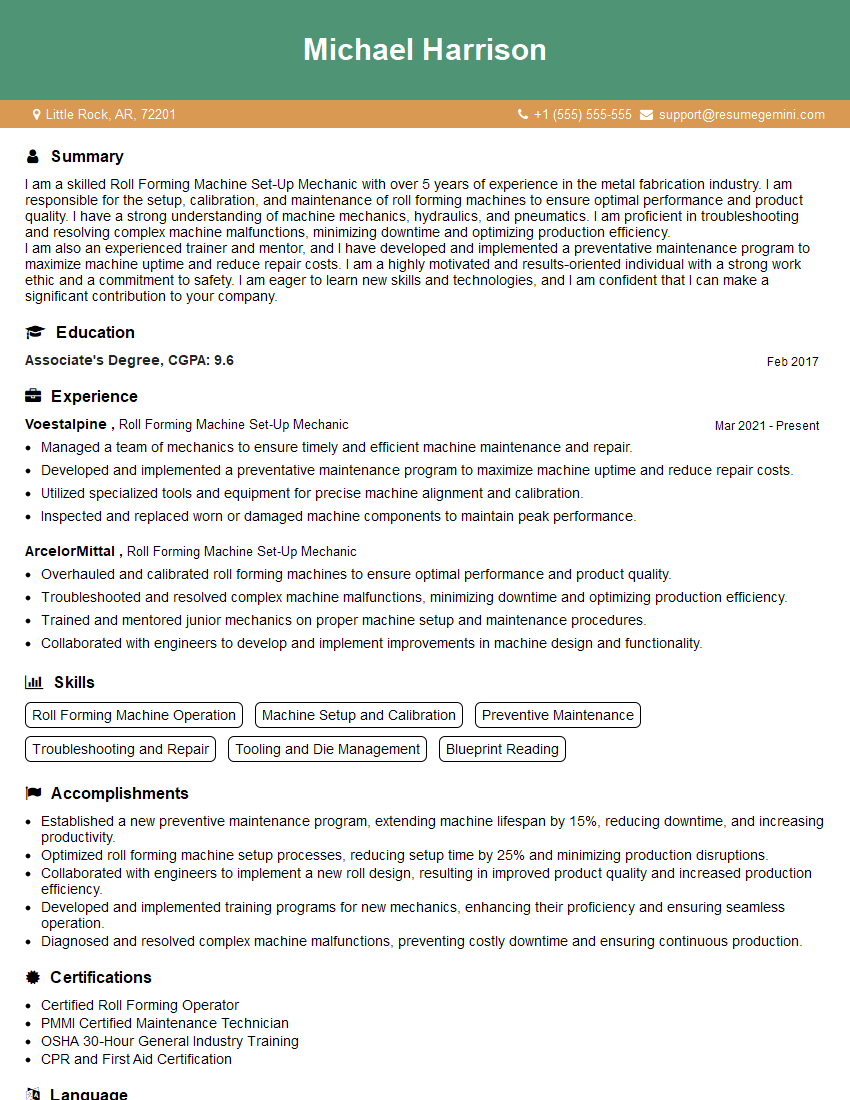

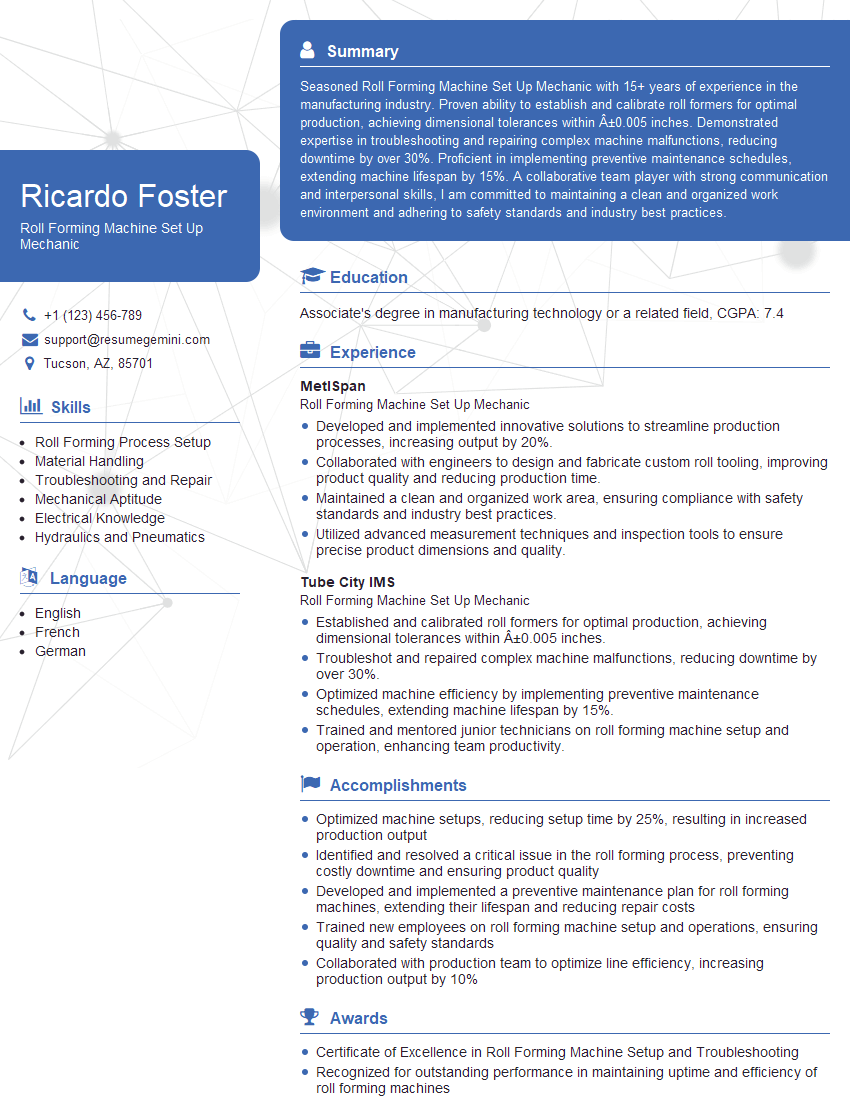

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Forming Machine Set-Up Mechanic

1. What are the key responsibilities of a Roll Forming Machine Set-Up Mechanic?

- Set up and adjust roll forming machines to produce metal components.

- Troubleshoot and repair roll forming machines.

- Maintain and calibrate roll forming machines.

- Train operators on how to use roll forming machines.

- Follow safety procedures and regulations.

2. What are the different types of roll forming machines?

Types of Roll Forming Machines

- Single-station roll forming machines

- Multi-station roll forming machines

- Continuous roll forming machines

- Tube roll forming machines

- Pipe roll forming machines

3. What are the different types of roll forming dies?

- Flat roll forming dies

- Contoured roll forming dies

- Progressive roll forming dies

- Compound roll forming dies

- Cluster roll forming dies

4. What are the different materials that can be roll formed?

- Steel

- Aluminum

- Copper

- Brass

- Stainless steel

5. What are the different factors that affect the quality of roll formed products?

- Machine setup

- Roll forming dies

- Material properties

- Speed of operation

- Lubrication

6. What are the different safety procedures that must be followed when operating roll forming machines?

- Wear proper safety gear.

- Keep hands away from moving parts.

- Do not operate machines when tired or under the influence of drugs or alcohol.

- Follow all posted safety signs and procedures.

- Report any unsafe conditions to your supervisor immediately.

7. How do you troubleshoot a roll forming machine?

- Start by identifying the problem.

- Check the machine for any loose parts or damaged components.

- Check the material being roll formed for any defects.

- Check the roll forming dies for any wear or damage.

- Check the machine settings to make sure they are correct.

8. How do you maintain a roll forming machine?

- Clean the machine regularly.

- Lubricate the machine according to the manufacturer’s recommendations.

- Inspect the machine for any wear or damage.

- Calibrate the machine regularly.

- Follow all maintenance procedures as outlined by the manufacturer.

9. What are some of the common problems that can occur with roll forming machines?

- Die wear

- Roll misalignment

- Material feeding problems

- Hydraulic problems

- Electrical problems

10. How do you choose the right roll forming dies for a particular job?

The type of roll forming dies that you choose will depend on the following factors:

- The material being roll formed.

- The shape of the part being roll formed.

- The speed at which the part is being roll formed.

- The accuracy required.

- The cost of the dies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Forming Machine Set-Up Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Forming Machine Set-Up Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Roll Forming Machine Set-Up Mechanic, you will be responsible for ensuring that roll forming machines are set up and operating correctly. Your key responsibilities will include:

1. Machine set-up and operation

– Setting up and operating roll forming machines to produce a variety of metal shapes and profiles. – Adjusting and maintaining roll tooling to ensure that products meet specifications. – Monitoring machine operation and making adjustments to ensure that product quality is maintained.

2. Troubleshooting and repair

– Troubleshooting and repairing roll forming machines to maintain optimal performance. – Identifying and resolving mechanical and electrical problems.

3. Preventive maintenance

– Performing preventive maintenance on roll forming machines to prevent potential problems. – Inspecting and lubricating moving parts.

4. Process improvement

– Working with other team members to identify process improvements that can increase machine efficiency and product quality.

Interview Tips

To help you ace your interview, consider the following tips:

1. Research the company and the position

– Visit the company’s website to learn about its products or services, its mission, and its culture. – Look for news articles or press releases about the company to get a sense of its recent developments. – Study the job description carefully so that you understand the key responsibilities and qualifications.

2. Practice answering common interview questions

– There are many resources available online and in libraries that can help you practice answering common interview questions. – It is helpful to prepare answers to questions about your skills, experience, and why you are interested in the position. – You may also be asked questions about your knowledge of roll forming machines and your troubleshooting abilities.

3. Be prepared to talk about your experience

– The interviewer will likely want to know about your previous experience working with roll forming machines. – Be prepared to talk about your specific responsibilities and how they relate to the requirements of the position. – You may also be asked about your experience with troubleshooting and repair.

4. Be confident and enthusiastic

– Confidence and enthusiasm are key to making a good impression in an interview. – Be yourself and let your personality shine through. – Dress professionally and arrive on time for your interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Roll Forming Machine Set-Up Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Roll Forming Machine Set-Up Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.