Feeling lost in a sea of interview questions? Landed that dream interview for Roll Forming Machine Set Up Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Roll Forming Machine Set Up Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

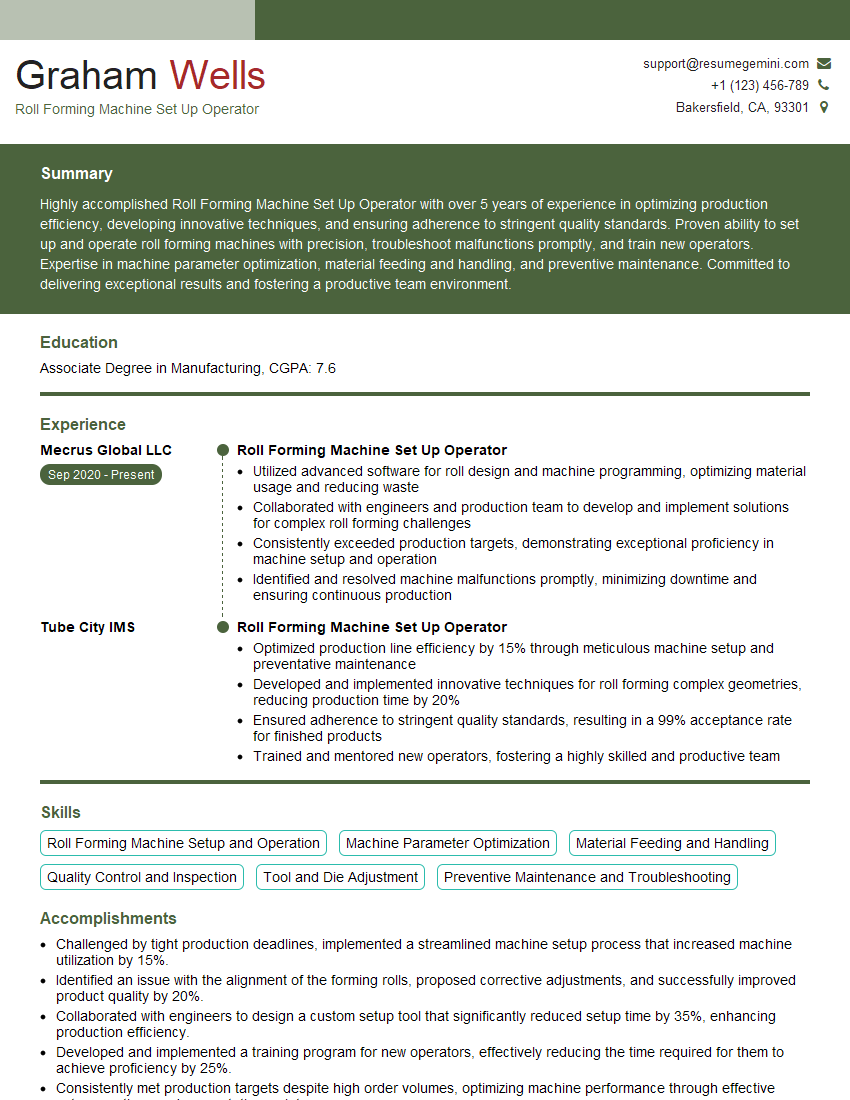

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Forming Machine Set Up Operator

1. what is a roll forming machine? describe working principle.

A roll forming machine is a machine that takes a long length of sheet metal and passes it through a series of rollers to form it into a specific cross-sectional shape. The rollers are typically made of hardened steel and have a specific pattern of grooves or ridges that shape the metal as it passes through.

The working principle of a roll forming machine is relatively simple. The metal sheet is fed into the machine, and it passes through a series of rollers. Each roller has a specific shape that it imparts to the metal. The metal is gradually shaped as it passes through each roller, and the final shape is achieved at the end of the machine.

2. Explain the different types of Roll forming machines?

Mechanical Roll Forming Machines

- These machines use a mechanical drive to power the rollers.

- They are typically used for simple roll forming operations.

Hydraulic Roll Forming Machines

- These machines use a hydraulic drive to power the rollers.

- They are typically used for more complex roll forming operations.

Computerized Roll Forming Machines

- These machines use a computer to control the operation of the rollers.

- They are typically used for high-precision roll forming operations.

3. what are the different types of roll forming operations?

- Cold roll forming: This process involves forming metal at room temperature.

- Hot roll forming: This process involves forming metal at elevated temperatures.

- Hydroforming: This process involves forming metal using a high-pressure fluid.

4. what are the advantages of roll forming?

- High precision: Roll forming can produce parts with very high precision.

- High production rates: Roll forming is a very fast process.

- Low cost: Roll forming is a relatively low-cost process.

- Versatility: Roll forming can be used to produce a wide variety of shapes and sizes.

5. what are the disadvantages of roll forming?

- Limited material thickness: Roll forming is limited to relatively thin materials.

- Complex shapes: Roll forming can be difficult to use to produce complex shapes.

6. what are the key factors to consider when choosing a roll forming machine?

- The type of metal being formed

- The thickness of the metal being formed

- The desired shape of the finished product

- The production rate required

- The budget

7. How to set up a roll forming machine?

The setup of a roll forming machine can vary depending on the specific machine, but there are some general steps that are typically followed:

- Install the roll forming dies. The roll forming dies are the tooling that gives the metal its shape. They are typically made of hardened steel and have a specific pattern of grooves or ridges.

- Adjust the roll forming machine settings. The roll forming machine settings include the speed of the rollers, the pressure of the rollers, and the temperature of the rollers.

- Feed the metal into the roll forming machine. The metal is typically fed into the machine in a coil.

- Start the roll forming machine. The roll forming machine will start to form the metal into the desired shape.

- Monitor the roll forming process. The operator should monitor the roll forming process to ensure that the metal is being formed correctly.

8. How to maintain a roll forming machine?

Regular maintenance is important to keep a roll forming machine running properly.

- Clean the roll forming machine. The roll forming machine should be cleaned regularly to remove any metal chips or debris.

- Lubricate the roll forming machine. The roll forming machine should be lubricated regularly to reduce friction and wear.

- Inspect the roll forming machine. The roll forming machine should be inspected regularly to identify any potential problems.

9. How to troubleshoot a roll forming machine?

If a roll forming machine is not working properly, there are a few things that can be done to troubleshoot the problem:

- Check the roll forming machine settings. The roll forming machine settings should be checked to ensure that they are correct.

- Inspect the roll forming dies. The roll forming dies should be inspected to ensure that they are not damaged.

- Check the metal being formed. The metal being formed should be checked to ensure that it is the correct type and thickness.

10. what are the safety precautions that should be taken when operating a roll forming machine?

- Wear appropriate safety gear. Safety gear includes safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Be aware of the location of the pinch points. Pinch points are areas where the metal can be caught between the rollers.

- Do not operate the roll forming machine if it is not in good working order.

- Follow all of the manufacturer’s instructions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Forming Machine Set Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Forming Machine Set Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A roll forming machine set up operator is responsible for setting up, operating, and maintaining roll forming machines used in the production of metal products. Key responsibilities include:

1. Set up and adjust roll forming machines

Set up and adjust roll forming machines according to specifications, including tooling, material, and process parameters.

- Install and adjust forming rolls, guides, and other components.

- Set up and calibrate sensors, gauges, and other control equipment.

2. Operate roll forming machines

Operate roll forming machines to produce metal products, monitoring machine operation and adjusting settings as needed.

- Load and feed material into the machine.

- Monitor machine operation and adjust settings to maintain product quality.

3. Maintain roll forming machines

Maintain roll forming machines to ensure optimal performance and prevent breakdowns.

- Inspect and clean machines regularly.

- Replace worn or damaged parts.

4. Troubleshoot and resolve issues

Troubleshoot and resolve issues with roll forming machines, identifying and correcting problems.

- Diagnose and repair electrical, mechanical, and hydraulic problems.

- Identify and correct problems with material flow, product quality, and machine operation.

Interview Tips

To prepare for an interview for a roll forming machine set up operator position, it is important to:

1. Research the company and the position

Learn about the company’s products, services, and culture. Research the specific position you are applying for and identify the key responsibilities and qualifications.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Practice your answers to common interview questions

Prepare for common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in front of a mirror or with a friend or family member.

- Use the STAR method to answer interview questions.

- Highlight your skills and experience that are relevant to the position.

3. Be prepared to discuss your experience and qualifications

Be prepared to discuss your experience and qualifications in detail. This includes your experience with roll forming machines, your knowledge of metalworking processes, and your ability to troubleshoot and resolve problems.

- Provide specific examples of your experience and accomplishments.

- Quantify your results whenever possible.

4. Ask questions about the company and the position

Asking questions at the end of an interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

- Ask questions about the company’s products, services, and culture.

- Ask questions about the specific position you are applying for.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roll Forming Machine Set Up Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.