Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roll Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

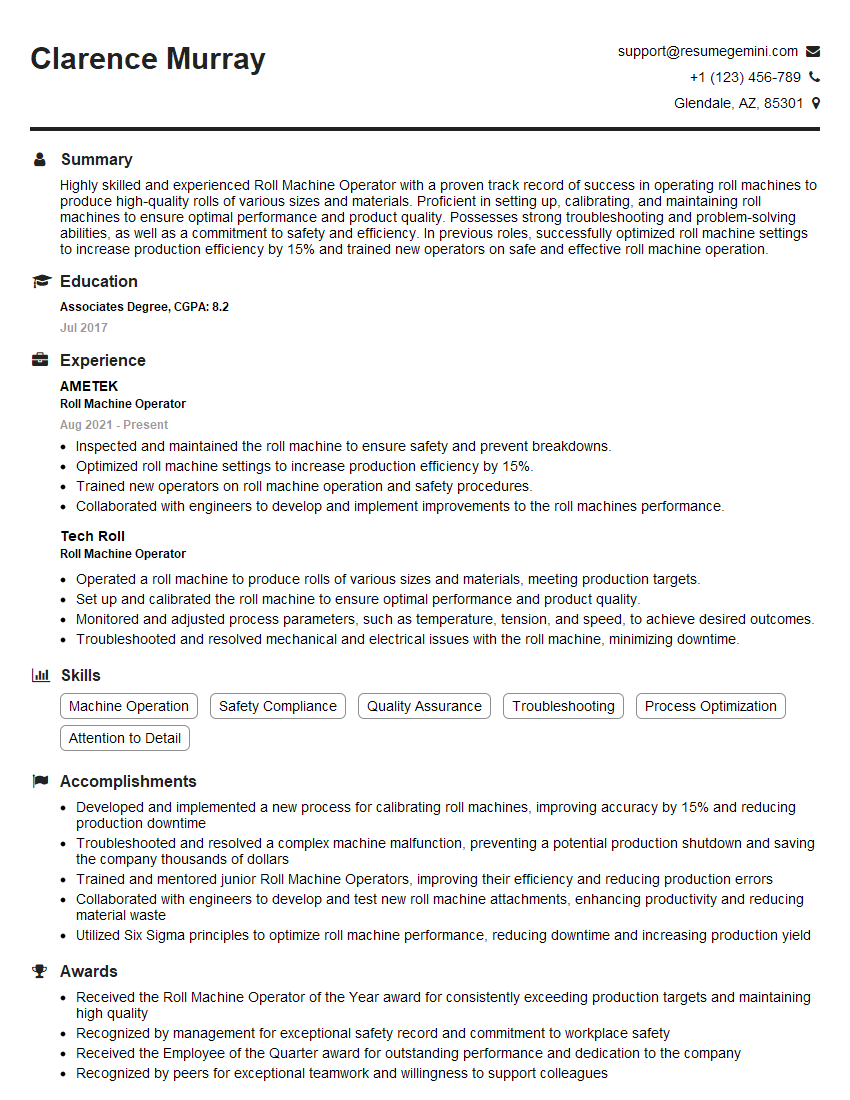

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Machine Operator

1. What are the key responsibilities of a Roll Machine Operator?

As a Roll Machine Operator, I would be responsible for:

- Operating and maintaining roll machines to produce rolls of paper, plastic, or other materials.

- Setting up and adjusting the machine according to specifications.

- Monitoring the machine during operation and making adjustments as needed.

- Inspecting the finished rolls for quality and defects.

- Following established safety procedures and maintaining a clean and organized work area.

2. What is the process of setting up a roll machine?

- First, I would ensure that the machine is properly cleaned and lubricated.

- Next, I would install the appropriate roll of material onto the machine.

- I would then adjust the machine settings according to the desired specifications, including the speed, tension, and temperature.

- Finally, I would run a test roll to verify that the machine is operating correctly.

3. Describe the different types of roll machines and their uses.

- Slitting machines are used to cut rolls of material into narrower widths.

- Sheeting machines are used to cut rolls of material into sheets of a specific size.

- Laminating machines are used to bond two or more layers of material together.

- Coating machines are used to apply a coating to a roll of material.

- Printing machines are used to print designs or text onto rolls of material.

4. How do you troubleshoot common roll machine problems?

When troubleshooting roll machine problems, I would first try to identify the source of the problem by observing the machine and its components.

Mechanical problems

- I would check for any loose or damaged parts, such as belts, gears, or bearings.

- I would also check for any misalignment of the machine’s components.

Electrical problems

- I would check for any loose or damaged electrical connections.

- I would also check the machine’s electrical components, such as the motor, controller, and sensors.

Material problems

- I would check the material for any defects, such as tears, wrinkles, or contamination.

- I would also check the material’s compatibility with the machine.

5. What are the safety precautions that must be taken when operating a roll machine?

- Always wear appropriate safety gear, such as gloves, eye protection, and earplugs.

- Never operate the machine with loose clothing or jewelry.

- Keep hands and other body parts away from moving parts.

- Be aware of the potential for pinch points and crushing hazards.

- Follow all established safety procedures and protocols.

6. What is the importance of preventative maintenance for roll machines?

Preventative maintenance is crucial for roll machines because it helps to prevent breakdowns, extend the machine’s lifespan, and maintain optimal performance.

- Regular maintenance can identify and address potential problems before they become major issues.

- It can also help to improve the machine’s efficiency and productivity.

- By keeping the machine in good condition, preventative maintenance can also help to reduce the risk of accidents and injuries.

7. What are some of the latest advancements in roll machine technology?

- Automated roll handling systems can reduce the need for manual labor and improve efficiency.

- Computerized control systems can provide precise control over the machine’s operation.

- New materials and coatings can improve the durability and performance of roll machines.

- Advanced sensors can detect potential problems and help to prevent breakdowns.

8. What are your strengths and weaknesses as a Roll Machine Operator?

My strengths as a Roll Machine Operator include my:

- Experience in operating and maintaining a variety of roll machines.

- Attention to detail and accuracy.

- Ability to troubleshoot and resolve problems quickly and efficiently.

- Strong work ethic and commitment to safety.

One area where I would like to improve is my knowledge of the latest advancements in roll machine technology.

9. Why are you interested in working as a Roll Machine Operator for our company?

I am interested in working as a Roll Machine Operator for your company because I am impressed with your commitment to quality and innovation.

- Your company has a reputation for producing high-quality products.

- You are also investing in new technologies to improve your operations.

- I believe that my skills and experience would be a valuable asset to your team.

10. Do you have any questions for me about the position or the company?

I am eager to learn more about the position and the company.

- What is the company culture like?

- What are the opportunities for professional development?

- What are the company’s plans for future growth?

Thank you for your time and consideration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roll Machine Operators are responsible for operating and maintaining roll machines used in the production of various products. Their primary duties involve ensuring efficient machine operation, monitoring product quality, and performing necessary maintenance and repairs.

1. Machine Operation

Operate roll machines to process raw materials or semi-finished products according to specified parameters.

- Load and unload materials into and from the machine.

- Monitor machine settings, such as speed, temperature, and pressure, to optimize production.

2. Quality Control

Inspect products produced by the roll machine for defects or inconsistencies.

- Use measuring tools to verify product dimensions and specifications.

- Identify and correct any deviations from quality standards.

3. Maintenance and Repair

Perform routine maintenance on roll machines to ensure optimal performance.

- Clean and lubricate machine components.

- Identify and troubleshoot mechanical or electrical problems.

4. Safety Compliance

Adhere to safety regulations and procedures to minimize risks.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures when servicing machines.

Interview Tips

Preparing for a Roll Machine Operator interview requires understanding the key responsibilities and expectations of the role. Here are some tips to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, history, and current projects. Understand the specific job requirements and responsibilities outlined in the job description.

2. Highlight Relevant Skills and Experience

Emphasize your practical experience operating roll machines, including your knowledge of machine settings, quality control procedures, and maintenance techniques. Quantify your accomplishments whenever possible, using specific examples to demonstrate your impact.

3. Demonstrate Attention to Detail

Roll Machine Operators must have a keen eye for detail to ensure product quality and safety. Highlight your ability to identify defects, measure products accurately, and follow precise instructions.

4. Emphasize Safety Consciousness

Safety is paramount in industrial environments. Showcase your understanding of safety protocols, your commitment to following procedures, and your ability to identify and mitigate potential hazards.

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress appropriately for the interview and arrive on time to demonstrate your professionalism and respect for the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Roll Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.