Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roll Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

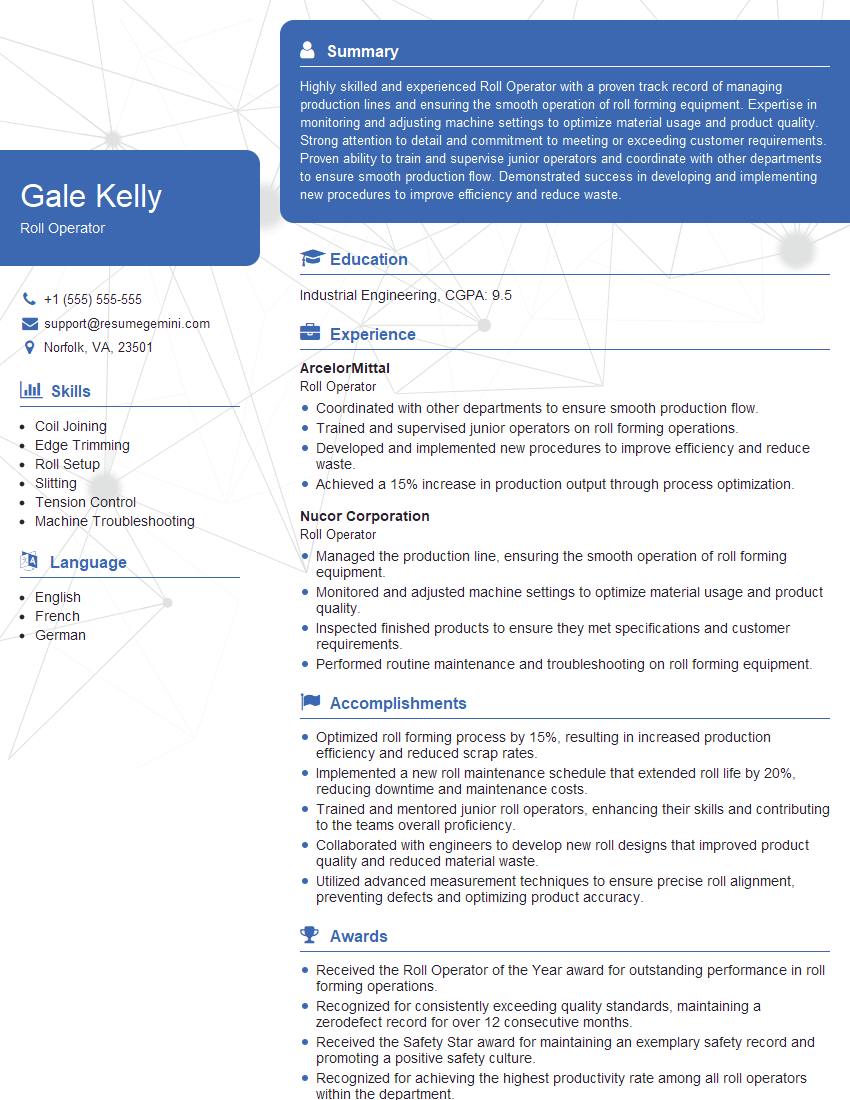

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Operator

1. What are the key responsibilities of a Roll Operator?

As a Roll Operator, my primary responsibilities would be to operate and maintain rolling machinery, ensure proper material flow, and monitor production quality. I would also be responsible for troubleshooting and resolving any operational issues promptly and efficiently.

2. Describe the different types of rolling processes and their applications.

Hot Rolling

- Involves passing metal through heated rollers to reduce its thickness and increase its strength.

- Used for producing structural components, such as beams, plates, and rods.

Cold Rolling

- Consists of rolling metal at room temperature to achieve precise dimensions and surface finishes.

- Used for manufacturing precision parts, such as automotive components and electronic devices.

3. Explain the process of setting up and operating a rolling machine.

- Adjusting roller settings and speed to meet production requirements.

- Loading and guiding material through the rollers.

- Monitoring process parameters and adjusting them as needed.

- Troubleshooting and resolving any operational issues.

4. What are the safety precautions that need to be taken when operating a rolling machine?

- Wearing appropriate safety gear, including gloves, earplugs, and safety glasses.

- Inspecting the machine and work area before starting operations.

- Ensuring proper ventilation and lighting.

- Avoiding loose clothing or jewelry that could get caught in the machinery.

5. How do you ensure the quality of rolled products?

- Performing regular inspections of the rolled material for defects and dimensional accuracy.

- Monitoring and adjusting process parameters to maintain consistent quality.

- Collaborating with quality control personnel to identify and resolve any quality issues.

6. What maintenance tasks are typically performed on rolling machines?

- Regular cleaning and lubrication of machinery.

- Replacing worn or damaged parts.

- Calibrating and adjusting machine settings.

- Conducting preventive maintenance to avoid breakdowns.

7. Describe your experience in troubleshooting and resolving rolling machine issues.

In my previous role as a Roll Operator, I encountered various machine issues, such as material jamming, roller slippage, and temperature fluctuations. I effectively applied my troubleshooting skills to identify the root causes of these issues and resolved them promptly, minimizing downtime and maintaining production efficiency.

8. What are the latest industry trends in rolling technology?

The rolling industry is constantly evolving, with advancements in automation, process control, and material science. I stay updated with the latest trends by attending industry conferences, reading technical publications, and engaging in discussions with colleagues and experts in the field.

9. How do you handle working in a fast-paced and demanding production environment?

In a fast-paced production environment, I thrive on maintaining focus and efficiency. I prioritize tasks, effectively manage my time, and work collaboratively with my team to meet production targets while adhering to quality standards.

10. What are your strengths and weaknesses as a Roll Operator?

Strengths:

- Strong technical skills and knowledge of rolling processes.

- Excellent troubleshooting and problem-solving abilities.

- Proven track record of maintaining high productivity and product quality.

Weaknesses:

- Limited experience with advanced automation systems.

- Working in high-stress environments can sometimes lead to fatigue.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Roll Operator is accountable for operating and monitoring rolling machines in various production environments. Their responsibilities encompass the setup, operation, and maintenance of rolling mills.

1. Machine Operation

Operate rolling machines to produce rolled metal products according to specifications

- Set up and adjust rolling mills for different product specifications

- Monitor machine operation and make adjustments as needed to ensure quality and efficiency

2. Production Management

Ensure production targets are met by managing and monitoring rolling processes

- Schedule and plan rolling operations to optimize production output

- Monitor production quality and identify any defects or issues

3. Maintenance and Troubleshooting

Maintain and troubleshoot rolling machines to ensure optimal performance

- Perform routine maintenance and repairs on rolling machines

- Identify and resolve operational issues or breakdowns

4. Safety and Compliance

Comply with safety regulations and ensure a safe work environment

- Follow established safety protocols and procedures

- Identify and mitigate potential safety hazards

Interview Tips

Preparing for a job interview as a Roll Operator requires a well-rounded approach. Here are some tips to help you stand out:

1. Research the Company and Role

Familiarize yourself with the company’s profile, industry, and specific requirements for the Roll Operator role. This knowledge will allow you to tailor your answers and demonstrate your understanding of the position.

- Visit the company’s website and social media pages to gain insights into their culture and values.

- Read industry news and articles to stay updated on the latest trends and technologies relevant to the role.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience related to rolling mill operations, including machine operation, production management, maintenance, and troubleshooting. Quantify your accomplishments whenever possible to showcase your impact.

- Provide specific examples of how you have successfully operated and maintained rolling machines.

- Quantify your contributions, such as increasing production output or reducing downtime.

3. Demonstrate Safety Consciousness

Safety is paramount in a Roll Operator role. Demonstrate your knowledge of safety protocols, risk assessment, and hazard mitigation. Share examples of your commitment to maintaining a safe work environment.

- Explain your understanding of industry safety standards and regulations.

- Provide an example of how you identified and addressed a potential safety hazard.

4. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Practice your answers to articulate your strengths and qualifications effectively.

- Prepare a concise and impactful 30-60 second introduction that highlights your key skills and experience.

- Anticipate questions related to your experience with specific rolling mill equipment or processes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roll Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.