Are you gearing up for a career in Roll or Tape Edge Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Roll or Tape Edge Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

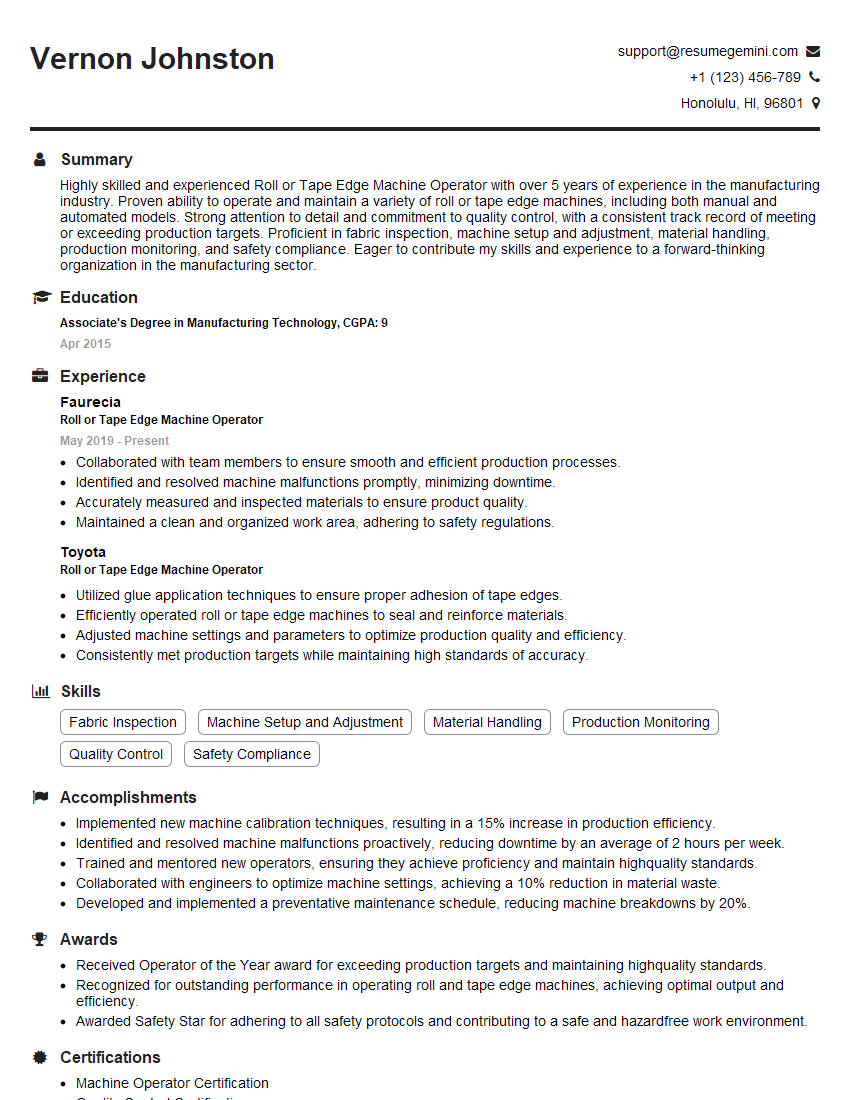

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll or Tape Edge Machine Operator

1. What are the types of Roll or Tape Edge Machines you have worked on?

As a Roll or Tape Edge Machine Operator, I have worked on various types of machines, including:

- Manual Roll Edge Machines

- Semi-Automatic Roll Edge Machines

- Automatic Roll Edge Machines

- Tape Edge Machines

2. What are the key quality control parameters for Roll Edge Machine operation?

Edge Quality

- Edge smoothness and consistency

- Absence of burrs or sharp edges

Dimensional Accuracy

- Maintaining specified edge width and thickness

- Ensuring proper alignment and fit of the edge

Surface Finish

- Achieving desired surface texture and reflectivity

- Preventing scratches or damage to the material

3. Describe the safety protocols you follow when operating Roll or Tape Edge Machines.

To ensure safety during Roll or Tape Edge Machine operation, I adhere to the following protocols:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs

- Inspecting the machine before each use to identify any potential hazards

- Following established lockout/tagout procedures when performing maintenance or repairs

- Being aware of my surroundings and maintaining a safe work area

- Reporting any safety concerns or incidents promptly

4. How do you handle machine breakdowns or malfunctions?

When faced with machine breakdowns or malfunctions, I follow these steps:

- Immediately stop the machine and disconnect the power source

- Identify the potential cause of the issue based on my knowledge and experience

- Refer to technical manuals or seek assistance from a supervisor or maintenance technician

- Perform basic troubleshooting steps, such as checking electrical connections or replacing fuses

- If unable to resolve the issue, I promptly report the malfunction and request assistance

5. What maintenance procedures do you perform on Roll or Tape Edge Machines?

To maintain optimal performance and safety, I regularly perform the following maintenance procedures on Roll or Tape Edge Machines:

- Cleaning and lubricating machine parts to prevent wear and tear

- Replacing worn or damaged components, such as blades, bearings, and belts

- Tightening loose bolts and connections to ensure stability and accuracy

- Calibrating the machine periodically to maintain dimensional accuracy

- Following manufacturer’s recommendations for scheduled maintenance and inspections

6. How do you optimize machine settings to achieve desired edge quality and efficiency?

To optimize machine settings for desired edge quality and efficiency, I consider the following factors:

- Material type and thickness

- Desired edge width and thickness

- Speed and feed rates

- Blade sharpness and condition

- Lubrication and cooling

7. How do you ensure the consistency of edge quality during high-volume production runs?

To maintain consistency of edge quality during high-volume production runs, I implement the following strategies:

- Standardizing machine settings and operating procedures

- Regularly monitoring edge quality and making adjustments as needed

- Using quality control tools, such as gauges and measuring devices

- Maintaining sharp blades and replacing them frequently

- Adhering to established quality standards and specifications

8. Describe your experience with troubleshooting and resolving edge quality issues.

Throughout my experience, I have encountered various edge quality issues and resolved them effectively:

- Rough or uneven edges: Identified dull or damaged blades, adjusted feed rates, and optimized lubrication

- Burrs or sharp edges: Replaced worn grinding wheels, adjusted grinding angles, and increased cooling

- Inconsistent edge width or thickness: Calibrated machine settings, checked for loose components, and ensured proper material alignment

- Surface damage or scratches: Replaced contaminated coolant, adjusted blade pressure, and polished the edges

9. What are the common challenges you have faced as a Roll or Tape Edge Machine Operator?

As a Roll or Tape Edge Machine Operator, I have encountered several common challenges:

- Material variations: Dealing with materials of different thicknesses, hardness, and finishes

- Machine maintenance: Identifying and resolving mechanical issues to maintain optimal performance

- Quality control: Ensuring consistency and meeting strict quality standards for edge quality

- Time constraints: Balancing production efficiency with maintaining high-quality output

- Safety: Adhering to safety protocols while working with sharp blades and heavy machinery

10. How do you stay updated with the latest advancements in Roll or Tape Edge Machine technology?

To stay current with advancements in Roll or Tape Edge Machine technology, I engage in continuous learning and development activities:

- Attending industry conferences and workshops

- Reading technical journals and articles

- Participating in online forums and discussions

- Seeking training opportunities from equipment manufacturers

- Collaborating with other professionals in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll or Tape Edge Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll or Tape Edge Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roll or Tape Edge Machine Operators play a crucial role in the production and finishing of fabrics and textiles. Their primary responsibilities encompass:

1. Machine Operation

Operate and maintain roll or tape edge machines to seal and reinforce fabric edges.

- Setting up and adjusting machines to specified parameters.

- Monitoring machine performance and ensuring smooth operation.

2. Fabric Handling

Handle fabrics and textiles efficiently to ensure proper feeding and processing.

- Loading and unloading fabrics from machines.

- Inspecting fabrics for defects and rejections.

3. Quality Control

Ensure the production of high-quality finished fabrics.

- Inspecting sealed edges for defects and adherence to specifications.

- Maintaining records of production quality and identifying areas for improvement.

4. Safety and Maintenance

Adhere to safety protocols and maintain a clean and organized work environment.

- Following established safety procedures.

- Performing basic maintenance tasks on equipment.

Interview Tips

To ace the interview for a Roll or Tape Edge Machine Operator position, candidates should consider the following preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, values, and the specific responsibilities of the role.

- Visit the company website and review job descriptions.

- Read articles or news related to the company’s products or services.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating roll or tape edge machines and handling fabrics.

- Quantify your experience and provide specific examples of your accomplishments.

- If you have experience in the textile industry, highlight your knowledge of different fabrics and their properties.

3. Demonstrate Quality Consciousness

Convey your commitment to producing high-quality products and adherence to specifications.

- Share examples where you have identified and resolved quality issues.

- Explain how you ensure that finished fabrics meet customer requirements.

4. Stress Safety and Teamwork

Emphasize your understanding of safety protocols and ability to work effectively in a team environment.

- Discuss your experience in following safety guidelines and maintaining a clean work area.

- Provide examples of how you have collaborated with colleagues to achieve production goals.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Roll or Tape Edge Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.