Are you gearing up for an interview for a Roll Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Roll Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

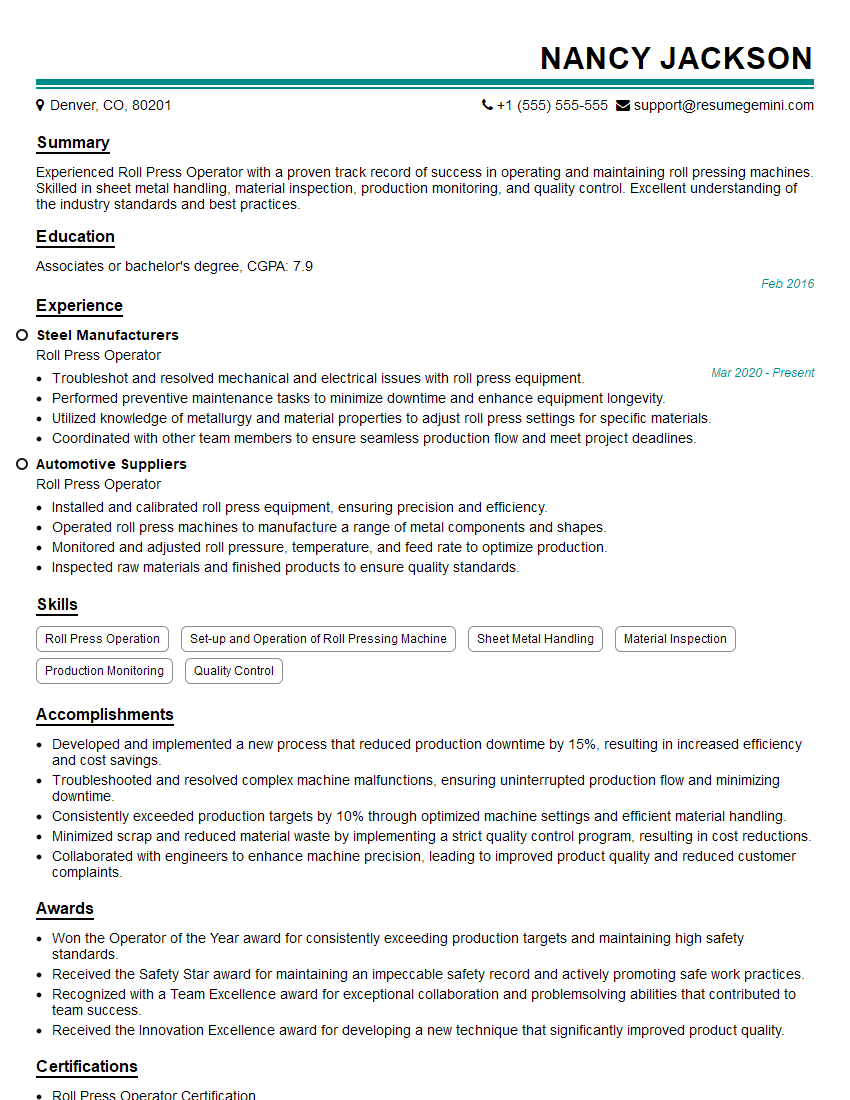

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Press Operator

1. Describe the key responsibilities and duties of a Roll Press Operator?

Sure, the key responsibilities and duties of a Roll Press Operator typically include:

- Operate and maintain roll presses to produce a variety of products

- Set up and adjust roll presses according to specifications

- Monitor press operations and make adjustments as needed

- Inspect products for quality and defects

- Troubleshoot and resolve press problems

- Maintain a clean and safe work area

- Follow all safety procedures

2. What are the different types of roll presses?

Mechanical Roll Press

- Uses mechanical force to apply pressure

- Can be manually or automatically operated

- Suitable for a wide range of materials

Hydraulic Roll Press

- Uses hydraulic pressure to apply force

- Provides precise control over pressure and speed

- Ideal for high-volume production

Pneumatic Roll Press

- Uses compressed air to apply pressure

- Fast and efficient

- Suitable for lightweight materials

3. What are the safety precautions that should be taken when operating a roll press?

When operating a roll press, it is crucial to adhere to the following safety precautions:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs

- Keep hands and loose clothing away from moving parts

- Never reach into the press while it is operating

- Be aware of pinch points and other hazards

- Follow all lockout/tagout procedures

- Report any unsafe conditions or concerns immediately

4. How do you troubleshoot problems with a roll press?

To troubleshoot problems with a roll press, I follow a systematic approach that includes:

- Identifying the problem and its symptoms

- Checking for loose or damaged parts

- Inspecting the electrical system

- Testing the hydraulic or pneumatic system

- Consulting the manufacturer’s manual

- Seeking assistance from a qualified technician if necessary

5. What is the importance of regular maintenance for roll presses?

Regular maintenance is crucial for roll presses because it helps to:

- Prevent breakdowns and costly repairs

- Extend the lifespan of the press

- Improve productivity and efficiency

- Ensure the safety of operators

- Maintain product quality

6. How do you measure and control the thickness of the material being rolled?

To measure and control the thickness of the material being rolled, I use the following methods:

- Thickness gauge: This device measures the thickness of the material as it passes through the press

- Micrometer: This precision instrument measures the thickness of the material at specific points

- Calipers: These tools can measure the thickness of the material before and after rolling

- By adjusting the roll gap and pressure, I can control the thickness of the rolled material

7. What are the different types of materials that can be rolled using a roll press?

A variety of materials can be rolled using a roll press, including:

- Metals (e.g., steel, aluminum, copper)

- Plastics

- Rubber

- Textiles

- Paper

8. What are the key factors that affect the quality of the rolled material?

The quality of the rolled material is influenced by several key factors, such as:

- Material properties

- Roll press settings (e.g., temperature, pressure, speed)

- Operator skills

- Maintenance and calibration of the roll press

9. How do you ensure that the rolled material meets the required specifications?

To ensure that the rolled material meets the required specifications, I take the following steps:

- Review the specifications and understand the tolerances

- Calibrate the roll press and measuring equipment

- Monitor the rolling process and make adjustments as needed

- Inspect the rolled material and compare it to the specifications

- Document the results and make any necessary corrections

10. Describe a challenging experience you faced while operating a roll press and how you overcame it.

During my previous role, I encountered a situation where the roll press was producing inconsistent material thickness. After troubleshooting the issue, I discovered that the pressure gauge was malfunctioning. I replaced the gauge, recalibrated the press, and conducted several test runs to ensure the problem was resolved. This experience taught me the importance of regular maintenance and calibration to ensure the accuracy and reliability of the roll press.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roll Press Operators play a pivotal role in the manufacturing process by operating and maintaining roll presses. They ensure efficient and productive operations, contributing to the company’s overall success.

1. Equipment Operation

Skilled in operating roll presses, the Roll Press Operator is responsible for setting up and adjusting equipment to meet specific requirements. They monitor the press during operation, ensuring optimal performance and product quality.

- Set up and adjust roll press according to specifications.

- Monitor press operation, checking for any deviations or malfunctions.

- Make necessary adjustments to maintain press performance and produce quality products.

2. Material Handling

Handling materials effectively is crucial to the Roll Press Operator’s role. They are responsible for loading and unloading materials into the press, ensuring proper alignment and positioning. They also monitor material flow and make adjustments as needed to prevent interruptions.

- Load and unload materials into and out of the press safely and efficiently.

- Ensure proper alignment and positioning of materials to achieve desired results.

- Monitor material flow and make adjustments to prevent interruptions or damage.

3. Quality Control

Maintaining product quality is a top priority for Roll Press Operators. They inspect materials before and after pressing to identify any defects or non-conformities. They also take measurements and make adjustments to ensure that products meet specifications.

- Inspect materials before and after pressing for defects or non-conformities.

- Take measurements and make adjustments to ensure products meet specifications.

- Maintain records and documentation related to product quality.

4. Equipment Maintenance

Roll Press Operators are responsible for performing routine maintenance on the equipment to ensure its longevity and reliability. They clean, lubricate, and inspect the press regularly, identifying and addressing any potential issues.

- Clean, lubricate, and inspect the press regularly to maintain optimal performance.

- Identify and address potential issues before they lead to breakdowns.

- Maintain a clean and organized work area to prevent accidents and ensure efficiency.

Interview Tips

Interview preparation is essential for a successful outcome. Here are few tips to help you prepare effectively and ace your interview as a Roll Press Operator:

1. Research the Role and Company

Before the interview, take the time to learn about the company and its operations. Visit their website and read industry-related articles to gain insights into the company’s culture, products, and market position. Understanding the company’s background will help you align your skills and experience with their needs.

- Visit the company’s website to learn about their business, products, and services.

- Read industry-related articles to gain insights into the company’s market position and industry trends.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers. Anticipate questions about your work experience, skills, and knowledge of roll presses. Prepare concise and well-structured answers that highlight your strengths and qualifications for the role.

- Prepare for questions about your work experience and skills.

- Practice answering questions about your knowledge of roll presses and related equipment.

3. Highlight Your Relevant Experience

Emphasize your relevant work experience and skills during the interview. Focus on quantifying your achievements by providing specific examples of your contributions to previous roles. Use the STAR method (Situation, Task, Action, Result) to structure your answers and showcase your abilities.

- Quantify your achievements by providing specific examples of your contributions.

- Use the STAR method to structure your answers and highlight your skills and experience.

4. Demonstrate Your Motivation and Eagerness

Convey your enthusiasm for the role and your eagerness to contribute to the company’s success. Express your interest in the company’s products, services, and industry, and explain how your skills and experience can add value to their operations. Show that you are a motivated and driven individual who is committed to the role.

- Express your interest in the company’s products, services, and industry.

- Explain how your skills and experience can add value to the company’s operations.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Roll Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Roll Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.