Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roll Sheeting Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

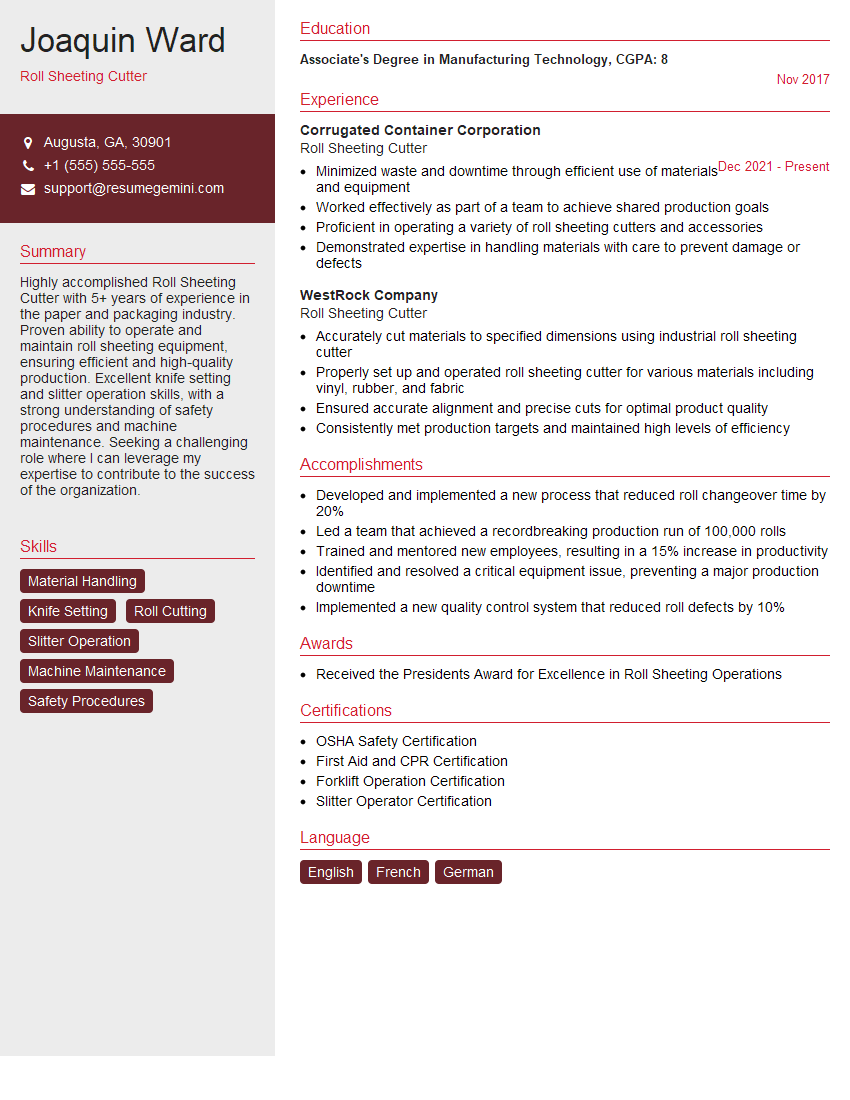

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Sheeting Cutter

1. What are the different types of roll sheeting cutters and their uses?

- Automatic Roll Sheeting Cutter: Designed for high-volume production, automatically feeding and cutting rolls of material with precision.

- Semi-Automatic Roll Sheeting Cutter: Offers greater flexibility than automatic cutters, allowing for manual positioning of the material before cutting.

- Manual Roll Sheeting Cutter: Requires manual operation throughout the cutting process, providing maximum control over the cut length and accuracy.

2. What are the key safety precautions to observe when operating a roll sheeting cutter?

Proper Equipment Setup

- Ensure the cutter is properly installed and grounded.

- Inspect the cutter regularly for any damage.

Safe Operation

- Always wear appropriate safety gear, including safety glasses and gloves.

- Keep hands clear of the cutting area.

- Operate the cutter only when necessary.

3. How do you ensure accurate and precise cutting with a roll sheeting cutter?

- Proper Setup: Calibrate the cutter according to the material thickness and desired cut length.

- Blade Maintenance: Sharpen or replace blades regularly to maintain cutting precision.

- Material Handling: Handle the material carefully to avoid any distortions that can affect cutting accuracy.

4. What techniques can you employ to minimize waste when using a roll sheeting cutter?

- Optimized Cutting Patterns: Plan the cutting patterns to maximize material utilization and minimize waste.

- Scrap Management: Reuse or recycle scrap pieces for other applications.

- Regular Maintenance: Properly maintained cutters produce clean cuts, reducing scrap due to uneven cuts or tearing.

5. What are the common maintenance tasks required for a roll sheeting cutter?

- Blade Cleaning: Remove any debris or adhesive from the blade to ensure smooth cutting.

- Lubrication: Lubricate moving parts regularly to prevent wear and tear.

- Tension Adjustment: Ensure the tension on the material is appropriate for accurate cutting.

6. How do you troubleshoot common issues with a roll sheeting cutter, such as uneven cuts or tearing?

- Uneven Cuts: Check blade sharpness, material tension, and alignment of the cutter and material.

- Tearing: Inspect the blade for any nicks or damage, and ensure the material is fed smoothly without any tension issues.

7. What are your experiences in working with different types of materials on a roll sheeting cutter?

Share your experiences in handling various materials, such as paper, plastic, fabric, or other specialized materials, and how you adjusted the cutter settings and techniques to achieve optimal cutting results.

8. How do you handle high-volume orders on a roll sheeting cutter while maintaining accuracy and efficiency?

- Optimized Setup: Establish efficient cutting patterns and ensure the cutter is properly calibrated.

- Continuous Monitoring: Regularly inspect the cutter and material to prevent any issues that could slow down production.

9. What techniques do you use to ensure the safety of co-workers when operating a roll sheeting cutter?

- Clear Work Area: Maintain a clean and well-organized work area to prevent tripping hazards or clutter that could obstruct movement.

- Safety Communication: Communicate with co-workers to ensure everyone is aware of the cutter’s operation and potential hazards.

10. How do you stay updated on the latest advancements and best practices in roll sheeting cutter technology?

- Industry Events and Conferences: Attend trade shows and industry events to learn about new technologies and techniques.

- Online Resources: Explore online forums, articles, and manufacturer websites for information on best practices and advancements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Sheeting Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Sheeting Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Roll Sheeting Cutter is an experienced professional responsible for efficiently cutting rolls of various materials, such as paper, textiles, or plastic, into specified dimensions.

1. Material Preparation and Cutting

The cutter ensures the correct roll is loaded into the cutting machine, verifies dimensions, and adjusts settings accordingly.

- Loads and unloads heavy rolls of material onto the cutting machine

- Verifies material specifications and adjusts machine settings to achieve precise cuts

- Operates the cutting machine to cut materials into specified sizes and shapes

2. Quality Control and Inspection

The cutter performs thorough inspections to ensure the cut materials meet quality standards and specifications.

- Inspects cut materials for accuracy of dimensions, shape, and surface finish

- Identifies and corrects any defects or inconsistencies in the cutting process

- Maintains production records and quality control documentation

3. Machine Maintenance and Troubleshooting

The cutter performs regular maintenance and troubleshooting of the cutting machine to ensure efficient operation.

- Cleans and lubricates cutting machine components to maintain optimum performance

- Troubleshoots and resolves machine malfunctions to minimize downtime

- Reports any major maintenance or repair needs to supervisors

4. Safety and Compliance

The cutter strictly complies with safety regulations and company policies to ensure a safe work environment.

- Wears appropriate personal protective equipment (PPE) while operating cutting machines

- Follows established safety protocols to prevent accidents and injuries

- Maintains a clean and organized work area to minimize hazards

Interview Tips

Preparing well for an interview is crucial to making a positive impression. Here are some tips and hacks to help you ace your interview for a Roll Sheeting Cutter position:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products. This will demonstrate your interest and show that you have taken the time to understand the organization.

- Visit the company website and review their mission statement, services, and recent news

- Read industry publications and articles to gain insights into the company’s market position and competition

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice delivering your answers in a clear and concise manner.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and highlight your experiences

- Focus on quantifying your accomplishments and demonstrating how they have benefited your previous employers

3. Highlight Relevant Skills and Experience

Emphasize your abilities in material handling, cutting operations, and quality control. Share specific examples of how you have used these skills to achieve positive results.

- Mention any certifications or training programs you have completed in the relevant field

- Provide details about your experience in operating cutting machines and ensuring product quality

4. Be Professional and Enthusiastic

Dress appropriately and arrive on time for your interview. Maintain a positive attitude and show genuine enthusiasm for the position.

- Make eye contact, smile, and greet the interviewer with a firm handshake

- Speak clearly and confidently, and ask thoughtful questions to demonstrate your interest

5. Follow Up

Within 24 hours of the interview, send a thank-you note to the interviewer. Reiterate your interest in the position and express your appreciation for their time.

- Use the thank-you note to address any points you may have missed during the interview

- Offer additional information or references if requested

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Roll Sheeting Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Roll Sheeting Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.