Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roll Threader Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

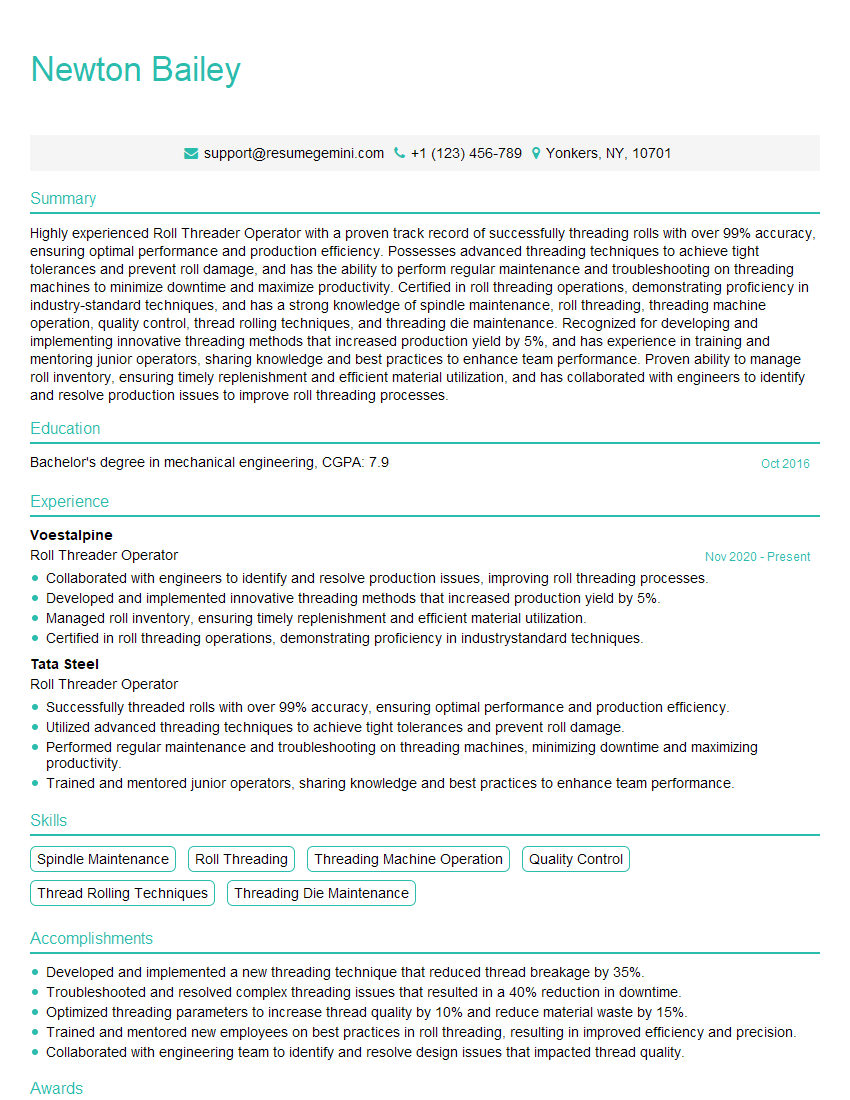

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Threader Operator

1. Can you describe the process of roll threading?

Roll threading is a cold forming process that uses a set of rotary dies to form threads onto a workpiece. The workpiece is fed between the dies, which have raised threads on their surfaces. As the dies rotate, they force the workpiece to conform to their shape, creating threads on the workpiece’s surface.

2. What are the different types of roll threading machines?

CNC roll threading machines

- Computer Numerical Controlled (CNC) roll threading machines use a computer program to control the movement of the dies and the workpiece. This allows for precise control of the thread pitch and diameter.

Manual roll threading machines

- Manual roll threading machines require the operator to manually control the movement of the dies and the workpiece. This type of machine is typically used for small-batch production or for threading large workpieces that cannot be accommodated by a CNC machine.

3. What are the advantages of roll threading?

- Roll threading is a relatively fast and efficient process.

- Roll threading produces threads that are strong and durable.

- Roll threading can be used to produce a variety of thread types, including external and internal threads.

4. What are the disadvantages of roll threading?

- Roll threading can only be used on certain types of materials, such as metals and plastics.

- Roll threading can be expensive, especially for small-batch production.

- Roll threading can produce burrs on the workpiece, which may need to be removed.

5. What are the different types of dies used in roll threading?

Flat dies

- Flat dies have a flat surface with raised threads on their surface. They are typically used for threading small-diameter workpieces.

Cylindrical dies

- Cylindrical dies have a cylindrical surface with raised threads on their surface. They are typically used for threading large-diameter workpieces.

Segmented dies

- Segmented dies are made up of several segments that can be adjusted to accommodate different workpiece diameters. They are typically used for threading workpieces with complex thread profiles.

6. How do you select the correct dies for a roll threading operation?

- The correct dies for a roll threading operation are selected based on the workpiece material, the thread pitch, the thread diameter, and the workpiece length.

- It is important to consult with the die manufacturer to ensure that the correct dies are selected for the specific application.

7. How do you set up a roll threading machine?

- To set up a roll threading machine, the operator must first install the correct dies into the machine.

- The operator must then adjust the machine settings, such as the thread pitch, the thread diameter, and the workpiece feed rate.

- The operator must also ensure that the workpiece is properly aligned with the dies.

8. How do you operate a roll threading machine?

- To operate a roll threading machine, the operator must first load the workpiece into the machine.

- The operator must then start the machine and allow the dies to rotate.

- The operator must monitor the machine during operation to ensure that the workpiece is being threaded correctly.

9. How do you troubleshoot a roll threading machine?

- If a roll threading machine is not working properly, the operator should first check the following:

- The dies are installed correctly.

- The machine settings are correct.

- The workpiece is properly aligned with the dies.

- If the problem cannot be resolved, the operator should contact the machine manufacturer for assistance.

10. What are the safety precautions that must be taken when operating a roll threading machine?

- The operator must wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- The operator must keep their hands away from the rotating dies.

- The operator must not attempt to remove a workpiece from the machine while it is running.

- The operator must keep the machine area clean and free of debris.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Threader Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Threader Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roll Threader Operators are responsible for operating and maintaining roll threading machines. They ensure that the machines are running smoothly and efficiently, and that the threads produced meet the required specifications. Key responsibilities include:1. Operating Roll Threading Machines

– Threading – Operating the roll threading machine to produce threads on metal rods, bars, pipes, or other cylindrical workpieces. – Monitoring – Monitoring the threading process to ensure that the threads are being produced to the correct specifications. – Adjusting – Adjusting the machine settings to ensure that the threads are of the correct size, pitch, and depth.

2. Maintaining Roll Threading Machines

– Cleaning – Cleaning and lubricating the machine to ensure that it is in good working order. – Inspecting – Inspecting the machine regularly for any signs of wear or damage. – Repairing – Performing minor repairs to the machine, such as replacing worn parts.

3. Quality Control

– Measuring – Measuring the threads produced by the machine to ensure that they meet the required specifications. – Rejecting – Rejecting any threads that do not meet the required specifications.

4. Safety

Following safety procedures to ensure the safety of themselves and others in the workplace.

Interview Tips

Preparing for an interview can be daunting, but with the right tips, you can increase your chances of success. Here are some interview preparation tips to help you ace your interview for a Roll Threader Operator position:

1. Research the Company and the Position

Take the time to learn about the company you are applying to and the specific position you are interviewing for. This will help you understand the company’s culture, values, and goals. Researching the position will give you insights into the responsibilities, skills, and experience required for the role.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience as a Roll Threader Operator. Be prepared to discuss your experience in operating and maintaining roll threading machines, as well as your quality control procedures. Providing specific examples of your work will help the interviewer to assess your abilities.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. Arrive on time for your interview to show the interviewer that you are punctual and respectful of their time. Being prepared and professional will demonstrate your interest in the position and your commitment to making a good impression.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Roll Threader Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Roll Threader Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.