Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roll Tube Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

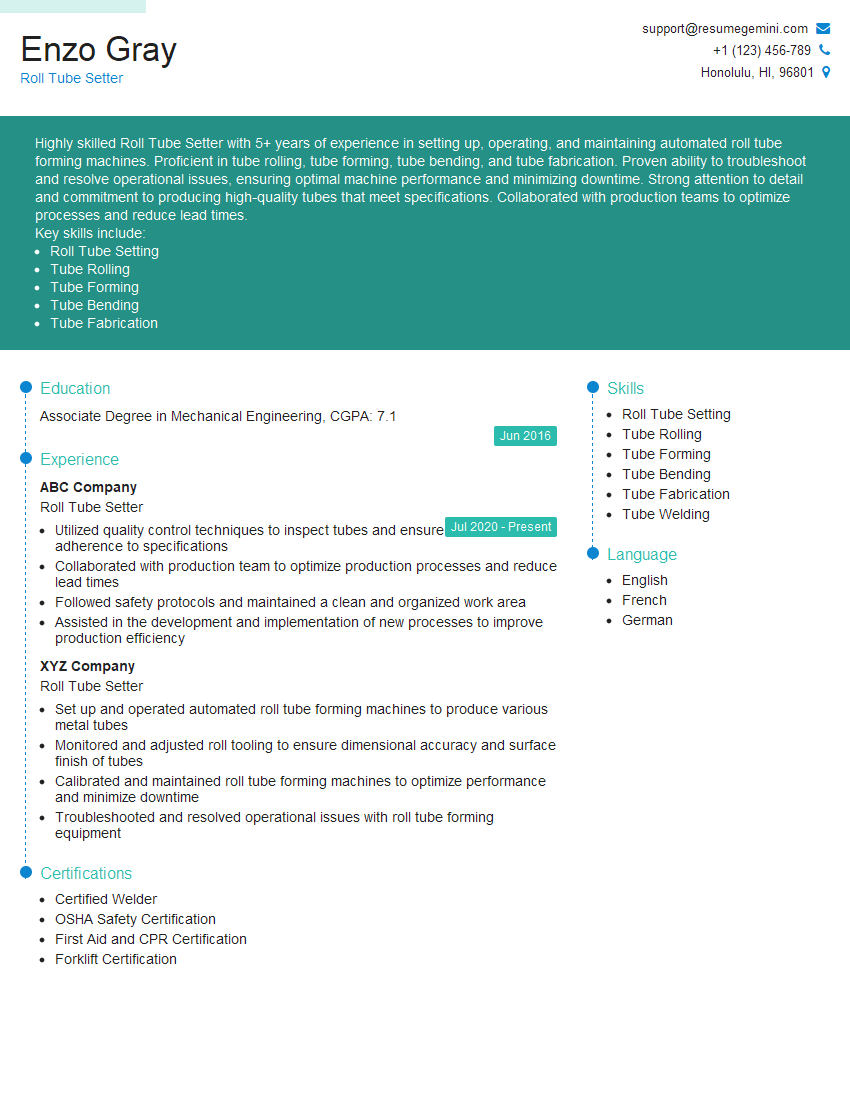

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Tube Setter

1. How do you set up a roll tube setter for a specific job?

When setting up a roll tube setter for a specific job, I follow these steps:

- Review the job specifications to determine the required tube size, shape, and material.

- Select the appropriate dies and mandrels for the job.

- Install the dies and mandrels into the machine and adjust the settings according to the manufacturer’s instructions.

- Load the tube into the machine and secure it in place.

- Set the machine speed and feed rate based on the material being used and the desired results.

- Start the machine and monitor it during operation to ensure proper forming.

2. What types of materials can be formed using a roll tube setter?

Metals

- Steel

- Aluminum

- Copper

- Brass

Plastics

- ABS

- PVC

- Polypropylene

- Polyethylene

3. What are the safety precautions that should be followed when operating a roll tube setter?

When operating a roll tube setter, it is crucial to follow these safety precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure that the machine is properly grounded and that all guards are in place.

- Keep hands and loose clothing away from moving parts.

- Do not operate the machine if it is damaged or not functioning properly.

- Be aware of the potential for pinch points and take precautions to avoid them.

4. How do you maintain a roll tube setter to ensure optimal performance?

Regular maintenance is essential to ensure optimal performance of a roll tube setter:

- Clean the machine regularly to remove any dirt, debris, or metal shavings.

- Lubricate all moving parts according to the manufacturer’s instructions.

- Inspect the dies and mandrels for wear or damage, and replace them if necessary.

- Check the machine’s calibration regularly to ensure accurate forming.

- Follow the manufacturer’s recommended maintenance schedule for specific maintenance tasks.

5. What are some common problems that can occur when using a roll tube setter, and how can they be resolved?

Some common problems that can occur when using a roll tube setter include:

Tube deformation

- Using the wrong dies or mandrels for the job.

- Improperly adjusting the machine settings.

- Overloading the machine.

Machine malfunction

- Electrical problems.

- Mechanical failures.

- Hydraulic leaks.

6. How do you determine the correct roll gap for a specific tube forming job?

To determine the correct roll gap for a specific tube forming job:

- Measure the outside diameter (OD) of the tube.

- Subtract the desired wall thickness from the OD.

- Divide the result by 2 to get the roll gap.

For example, if you have a tube with an OD of 1 inch and a desired wall thickness of 0.1 inch, the roll gap would be 0.45 inches.

7. What is the difference between a roll tube setter and a tube bender?

A roll tube setter and a tube bender are both used to form tubes, but they work in different ways:

Roll tube setter

- Forms tubes by passing them through a series of rotating dies.

- Can be used to form a wide variety of shapes.

- Typically used for high-volume production.

Tube bender

- Forms tubes by bending them around a mandrel.

- Can be used to form complex shapes.

- Typically used for low-volume production.

8. What are the different types of dies that can be used in a roll tube setter?

There are several different types of dies that can be used in a roll tube setter, including:

- Round dies: Used to form round tubes.

- Square dies: Used to form square tubes.

- Rectangular dies: Used to form rectangular tubes.

- Oval dies: Used to form oval tubes.

- Custom dies: Used to form tubes with unique shapes.

9. How do you troubleshoot a roll tube setter that is not forming tubes properly?

If a roll tube setter is not forming tubes properly, there are several potential causes to troubleshoot:

- Incorrect die or mandrel selection.

- Improper machine settings.

- Mechanical problems with the machine.

- Dull or damaged dies.

- Improper lubrication.

By checking these areas, you can typically identify the cause of the problem and take steps to resolve it.

10. What is the typical production rate of a roll tube setter?

The typical production rate of a roll tube setter depends on several factors, including:

- The type of machine.

- The material being formed.

- The complexity of the shape being formed.

- The operator’s skill level.

In general, a roll tube setter can produce hundreds or even thousands of tubes per hour.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Tube Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Tube Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roll Tube Setters are responsible for setting up and operating roll forming machines to produce cylindrical tubes and pipes. They work with a variety of materials, including steel, aluminum, and plastic, and may also be involved in the quality control process.

1. Set up and operate roll forming machines

Roll Tube Setters must be able to set up and operate roll forming machines to produce cylindrical tubes and pipes. This involves adjusting the machine’s settings to ensure that the tubes are produced to the correct dimensions and tolerances.

- Adjust the machine’s settings to ensure that the tubes are produced to the correct dimensions and tolerances.

- Monitor the machine’s operation to ensure that it is running smoothly and producing quality products.

2. Inspect the finished products

Roll Tube Setters must be able to inspect the finished products to ensure that they meet the required specifications. This involves checking the tubes for defects, such as cracks, dents, and scratches.

- Check the tubes for defects, such as cracks, dents, and scratches.

- Measure the tubes to ensure that they are produced to the correct dimensions and tolerances.

- Reject any tubes that do not meet the required specifications.

3. Troubleshoot and repair problems

Roll Tube Setters must be able to troubleshoot and repair problems with the roll forming machines. This involves identifying the source of the problem and taking steps to correct it.

- Identify the source of the problem by observing the machine’s operation and checking for error messages.

- Take steps to correct the problem, such as adjusting the machine’s settings or replacing worn parts.

- Test the machine to ensure that the problem has been corrected.

4. Maintain the roll forming machines

Roll Tube Setters must be able to maintain the roll forming machines to ensure that they are operating at peak performance. This involves cleaning and lubricating the machines, as well as replacing worn parts.

- Clean and lubricate the machines to prevent them from becoming damaged.

- Replace worn parts to ensure that the machines are operating at peak performance.

- Inspect the machines regularly to identify any potential problems.

Interview Tips

In addition to the technical skills required for the job, Roll Tube Setters should also have strong communication and interpersonal skills. They must be able to work independently and as part of a team, and they must be able to follow instructions and take direction. When preparing for an interview for a Roll Tube Setter position, it is important to be able to clearly and concisely explain your experience and skills. You should also be able to answer questions about your knowledge of the roll forming process and your experience in troubleshooting and repairing problems. Below are some additional tips for acing your interview:

1. Do your research

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and clearly.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Roll Tube Setter. Be prepared to discuss your experience in setting up and operating roll forming machines, inspecting the finished products, troubleshooting and repairing problems, and maintaining the machines.

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic and positive about their work. Be sure to convey your passion for the roll forming process and your desire to learn more about it.

5. Be yourself

The most important thing is to be yourself and let the interviewer see the real you. If you are genuine and authentic, the interviewer will be more likely to see your potential and give you a chance to prove yourself.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roll Tube Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!