Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rolled Glass Crosscutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

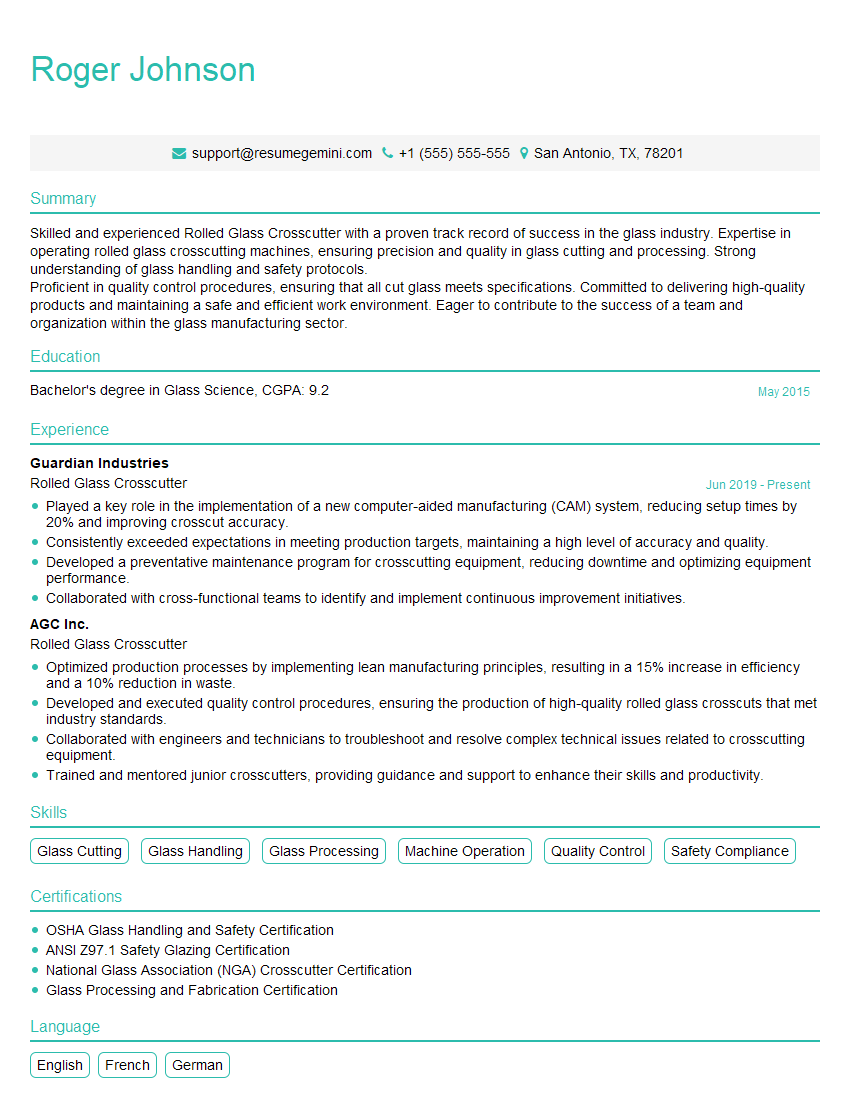

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rolled Glass Crosscutter

1. Can you explain the process of cutting rolled glass using a crosscutter?

The process of cutting rolled glass using a crosscutter involves several steps:

- Preparation: Measure and mark the desired cutting line on the glass using a glass marking tool.

- Scoring: Position the glass on the crosscutter and align the cutting wheel with the marked line. Apply downward pressure and slide the wheel along the line to create a shallow score.

- Snapping: After scoring, place a cold finger (a metal rod) along the score line and apply upward pressure to snap the glass cleanly along the score.

- Smoothing: Use a glass grinder or sandpaper to smooth any rough edges or sharp points.

2. What factors should be considered when selecting a crosscutter for rolled glass?

Cutting Capacity:

- Ensure the crosscutter has a cutting capacity that meets the thickness and width of the rolled glass you intend to cut.

Accuracy:

- Choose a crosscutter with precise cutting guides and a sharp cutting wheel to ensure straight and accurate cuts.

Safety Features:

- Look for crosscutters with safety features, such as a protective shield, dust collector, and non-slip feet, to minimize the risk of accidents.

Durability:

- Opt for a crosscutter made from durable materials that can withstand frequent use and heavy-duty cutting.

3. How do you maintain the cutting wheel of a crosscutter to ensure optimal performance?

Maintaining the cutting wheel of a crosscutter involves the following steps:

- Regular Lubrication: Apply a few drops of cutting oil or lubricant to the wheel periodically to reduce friction and prevent wear.

- Cleaning: Use a clean cloth or brush to remove any glass particles or debris that may accumulate on the wheel.

- Sharpening: If the wheel becomes dull, have it professionally sharpened to restore its cutting ability.

- Replacement: When the wheel is excessively worn or damaged, replace it with a new one to ensure precision cutting.

4. What are some common problems that can occur when using a crosscutter and how can they be resolved?

Poor Cutting Quality:

- Cause: Dull cutting wheel or uneven pressure during scoring.

- Solution: Replace the wheel or adjust the cutting pressure.

Glass Cracking or Tearing:

- Cause: Improper scoring or too much pressure during snapping.

- Solution: Score the glass correctly and apply appropriate force when snapping.

Wheel Binding:

- Cause: Accumulation of glass particles or debris on the wheel.

- Solution: Clean the wheel regularly.

5. How do you ensure the safety of yourself and others when operating a crosscutter?

To ensure safety when using a crosscutter, I follow these precautions:

- Wear Safety Gear: Protective gloves, safety glasses, and a dust mask are essential.

- Secure the Glass: Ensure the glass is securely held in place to prevent unexpected movement.

- Clear the Work Area: Remove any obstacles or debris from the work area.

- Proper Handling: Handle the glass cautiously to avoid cuts or breakage.

- Maintenance: Keep the crosscutter well-maintained to minimize the risk of malfunctions.

6. What is the difference between a crosscutter and a straight-line glass cutter?

Crosscutters and straight-line glass cutters are both used for cutting glass, but they differ in their functionality:

Crosscutter:

- Makes perpendicular cuts and is ideal for cutting wide pieces of glass.

- Uses a pivoting cutting head for precise cutting at various angles.

Straight-Line Glass Cutter:

- Cuts straight lines and is suitable for smaller pieces of glass.

- Has a fixed cutting head and requires manual guidance along a straight edge.

7. Can you explain how to cut a beveled edge on rolled glass using a crosscutter?

To cut a beveled edge on rolled glass using a crosscutter:

- Set the Bevel Angle: Adjust the crosscutter’s cutting head to the desired bevel angle.

- Mark the Cutting Line: Measure and mark the cutting line on the glass at the desired angle.

- Score the Glass: Position the glass on the crosscutter and align the cutting wheel with the marked line. Score the glass as usual.

- Snap the Glass: Place a cold finger at the start of the score line and snap the glass along the scored line.

- Grind the Edge: Use a glass grinder to smooth the beveled edge and remove any sharp points.

8. What techniques can be used to minimize waste when cutting rolled glass with a crosscutter?

To minimize waste when cutting rolled glass with a crosscutter:

- Plan the Cuts: Plan the cutting pattern to maximize the utilization of the glass.

- Nest the Cuts: Cut smaller pieces within larger cuts to use the leftover material.

- Use a Waste Bin: Keep a waste bin nearby to collect and reuse small scraps.

- Recycle Glass: Dispose of glass waste properly by recycling it.

9. How do you handle situations where the glass is too thick or the crosscutter is not suitable for the job?

When the glass is too thick or the crosscutter is not suitable for the job:

- Alternative Methods: Explore alternative cutting methods, such as a wet saw or diamond blade, for thicker glass.

- Specialized Equipment: If the crosscutter is not suitable, consider investing in specialized equipment designed for cutting thicker or irregularly shaped glass.

- Professional Assistance: Seek professional assistance from a glazier or glass supplier for complex or challenging cutting tasks.

10. How do you stay updated with the latest techniques and advancements in rolled glass crosscutting?

To stay updated with the latest techniques and advancements, I:

- Attend Industry Events and Workshops: Participate in industry events and workshops to learn about new technologies and best practices.

- Read Trade Publications and Online Resources: Regularly review trade publications and online forums to stay informed about industry trends and innovations.

- Connect with Professionals: Network with other rolled glass crosscutters and professionals to exchange knowledge and experiences.

- Seek Training Opportunities: Explore training programs or certifications to enhance my skills and learn about cutting-edge advancements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rolled Glass Crosscutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rolled Glass Crosscutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rolled Glass Crosscutters are responsible for cutting and processing rolled glass to meet customer specifications. They operate specialized machinery to cut glass to specific sizes and shapes and ensure the quality of the end product. The key responsibilities include:

1. Machinery Maintenance and Operation

Set up, operate, and maintain crosscutting machinery, ensuring proper functioning and accuracy.

2. Glass Handling and Processing

Unload, inspect, and handle rolled glass safely, minimizing damage and ensuring quality.

Cut rolled glass to precise dimensions and shapes using crosscutting machines.

3. Quality Control

Inspect cut glass for defects and compliance with specifications, ensuring customer satisfaction.

Measure and verify dimensions, thickness, and other quality parameters using measuring tools.

4. Production Planning and Management

Plan and manage production schedules to ensure timely delivery of orders.

Monitor production processes to identify and address bottlenecks, enhancing efficiency.

5. Safety and Compliance

Adhere to safety protocols, including wearing protective gear and following proper operating procedures.

Maintain a clean and organized work environment, ensuring compliance with industry regulations.

Interview Tips

To ace the interview for a Rolled Glass Crosscutter position, candidates should prepare thoroughly by considering the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, culture, and products. Research the glass industry and current trends to demonstrate your knowledge and interest.

2. Practice Your Skills

Practice operating crosscutting machinery, measuring glass, and inspecting for defects. This will enhance your confidence and ability to present your skills during the interview.

3. Highlight Your Experience

Emphasize your experience in glass handling, machinery operation, and quality control. Quantify your accomplishments and use specific examples to demonstrate your capabilities.

4. Showcase Your Problem-Solving Abilities

Highlight your problem-solving abilities by sharing examples of how you identified and resolved production challenges. Describe your approach to ensuring quality and efficiency.

5. Ask Meaningful Questions

Ask thoughtful questions about the company, the position, and the industry. This not only shows your interest but also allows you to gather valuable information.

6. Dress Professionally and Arrive on Time

Dress appropriately for the interview and arrive punctually. Your appearance and demeanor can make a significant impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rolled Glass Crosscutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.