Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rolled Materials Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rolled Materials Worker so you can tailor your answers to impress potential employers.

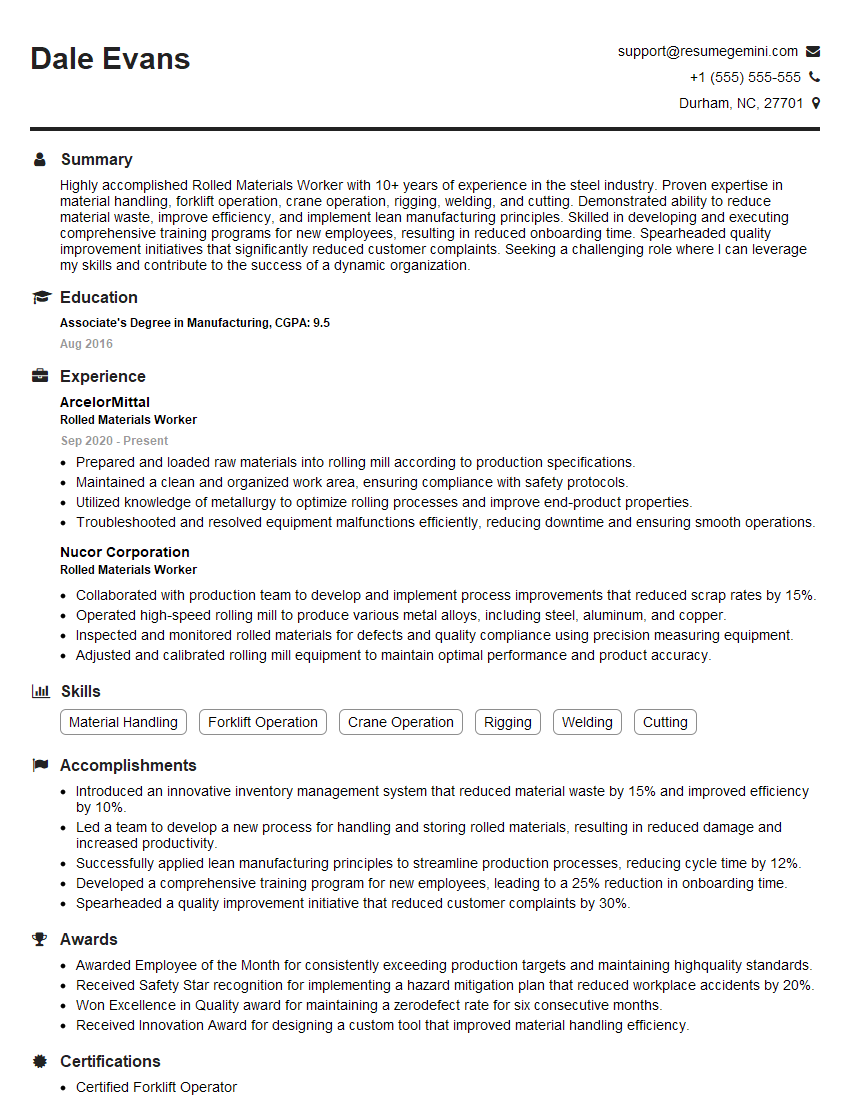

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rolled Materials Worker

1. How do you measure the thickness of rolled materials accurately?

To measure the thickness of rolled materials accurately, I use a micrometer or a thickness gauge. I ensure the surfaces of the materials are clean and free from any dirt or debris before taking measurements. I also take multiple measurements at different points on the material to ensure accuracy.

2. What are the different types of defects that can occur during the rolling process, and how do you identify them?

Types of Defects

- Scratches

- Dents

- Edge cracks

- Roll marks

Identification

- Visual inspection

- Dimensional measurements

- Ultrasonic testing

3. How do you maintain and adjust rolling mills to ensure optimal performance and prevent downtime?

I follow a regular maintenance schedule that includes lubrication, cleaning, and inspection of all components. I also check and adjust the alignment of the rolls, as well as the tension and speed of the material being rolled. By performing these tasks, I can prevent downtime and ensure the mill is operating efficiently.

4. What safety precautions should be taken when operating rolling mills?

- Wear appropriate personal protective equipment

- Be aware of pinch points and moving parts

- Keep the work area clean and free from hazards

- Follow lockout/tagout procedures

- Never operate the mill alone

5. How do you calculate the force required to roll a material to a given thickness?

To calculate the force required to roll a material to a given thickness, I use the following formula:

F = Y * t * w / d

- F = Force (Newtons)

- Y = Yield strength of the material (Pascals)

- t = Thickness of the material (meters)

- w = Width of the material (meters)

- d = Diameter of the rolls (meters)

6. What are the different types of lubricants used in rolling processes, and how do you select the appropriate one for a given application?

Types of Lubricants

- Oils

- Greases

- Waxes

- Dry lubricants

Selection Criteria

- Material being rolled

- Rolling temperature

- Rolling speed

- Desired surface finish

7. How do you troubleshoot common problems that occur during the rolling process?

- Material tearing

- Uneven thickness

- Surface defects

- Roll wear

To troubleshoot these problems, I use a variety of techniques, such as visual inspection, dimensional measurements, and vibration analysis.

8. How do you stay up-to-date on the latest technologies and best practices in the rolling industry?

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Consult with manufacturers and suppliers

- Participate in online forums and discussion groups

9. How do you ensure the quality of rolled materials meets customer specifications?

I perform regular quality checks throughout the rolling process, including dimensional measurements, surface inspection, and mechanical testing. I also maintain detailed records of all quality data and use it to identify and correct any issues that may arise.

10. What are your strengths and weaknesses as a Rolled Materials Worker?

Strengths

- Strong technical skills

- Excellent attention to detail

- Ability to work independently and as part of a team

- Commitment to safety

Weaknesses

- Limited experience with certain types of rolling mills

- Still learning about the latest technologies in the industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rolled Materials Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rolled Materials Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Rolled Materials Worker plays a crucial role in the production and processing of rolled materials, ensuring the efficient operation and maintenance of rolling mills and related equipment. Here are some key job responsibilities:

1. Production and Processing

• Monitors and operates rolling mills to produce rolled materials, such as sheets, strips, and bars, to meet production targets.

• Ensures that the materials meet the required specifications, dimensions, and surface finish.

• Adjusts and calibrates rolling equipment to optimize performance and maintain quality standards.

• Performs setup and changeover procedures for different product lines and materials.

2. Equipment Maintenance and Inspection

• Conducts routine maintenance and repairs on rolling mills and associated equipment.

• Inspects equipment regularly, identifies potential issues, and takes preventive measures to ensure smooth operation.

• Cleans and lubricates machinery to prevent breakdowns and extend equipment life.

• Participates in preventive maintenance programs and repairs, following established procedures.

3. Quality Control and Assurance

• Monitors and inspects rolled materials to ensure compliance with product specifications and quality standards.

• Uses measuring instruments to check dimensions, thickness, and surface finish.

• Identifies and corrects defects promptly to maintain quality and reduce waste.

4. Safety and Compliance

• Follows all safety regulations and procedures, including wearing appropriate safety gear.

• Identifies and reports potential hazards to ensure a safe work environment.

• Operates equipment safely and adheres to established safety protocols.

Interview Tips

To ace an interview for a Rolled Materials Worker position, consider the following tips:

1. Research the Company and Role

• Research the company’s industry, products, and reputation.

• Review the job description thoroughly and identify the key responsibilities and requirements.

• Prepare questions to ask the interviewer, demonstrating your interest and understanding of the role.

2. Showcase Your Technical Skills

• Highlight your experience in operating and maintaining rolling mills and related equipment.

• Provide specific examples of your technical abilities, including roll adjustment, calibration, and troubleshooting.

• Explain how your skills align with the company’s production and quality requirements.

3. Emphasize Safety

• Demonstrate your commitment to safety and your understanding of industrial safety practices.

• Share examples of your safety initiatives or contributions to improving plant safety.

• Explain how you would prioritize safety in your role as a Rolled Materials Worker.

4. Prepare for Behavior-Based Questions

• Practice answering behavioral-based questions using the STAR method (Situation, Task, Action, Result).

• Provide detailed examples of how you handled challenging situations, solved problems, and demonstrated teamwork.

• Relate your experiences to the specific requirements of the Rolled Materials Worker role.

5. Practice Common Interview Questions

• Prepare for common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

• Craft concise and compelling answers that highlight your skills, experience, and enthusiasm for the job.

• Practice your answers out loud to gain confidence and fluency.

6. Dress Professionally and Be Punctual

• Dress professionally and arrive at the interview on time.

• Maintain a positive and enthusiastic demeanor throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rolled Materials Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.