Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Roller Checker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Roller Checker so you can tailor your answers to impress potential employers.

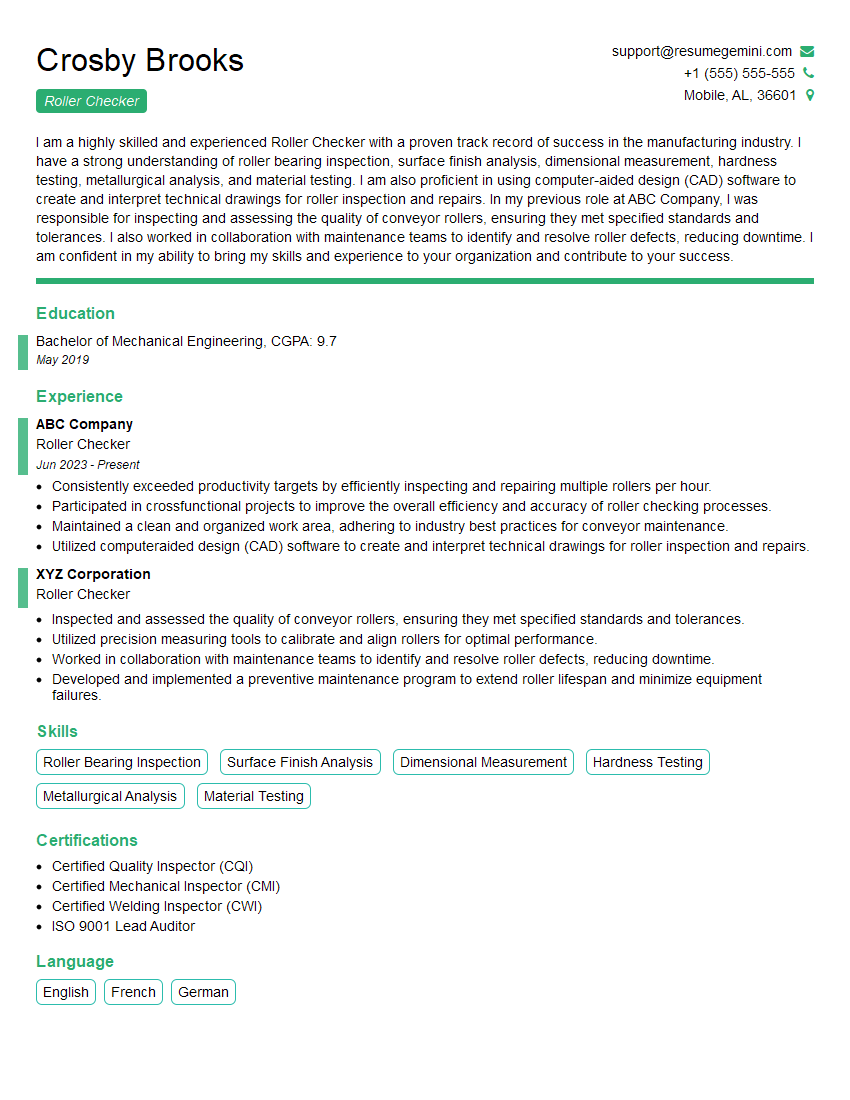

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roller Checker

1. Can you describe common quality defects in steel rollers?

- Spalling: Surface cracking and chipping due to thermal stress, fatigue, or poor lubrication.

- Wear: Gradual reduction in roller diameter due to friction and abrasion.

- Indentation: Dents or marks on the roller surface caused by impact or excessive pressure.

- Corrosion: Chemical degradation of the roller surface due to moisture, acids, or other corrosive agents.

- Out-of-roundness: Distortion of the roller’s shape, resulting in non-uniform thickness or profile.

2. Explain the methodology for conducting ultrasonic testing on steel rollers.

Scanning and Setup

- Select appropriate ultrasonic probe and couplant.

- Set up the scanner to cover the desired area and detect defects of specific sizes.

- Calibrate the equipment using a known defect standard.

Data Acquisition and Analysis

- Move the probe systematically over the roller surface, collecting data on any defects encountered.

- Analyze the data to determine the size, location, and type of defects present.

- Generate a report summarizing the findings and providing recommendations for repair or replacement.

3. What are the different types of surface treatments applied to steel rollers, and what is their purpose?

- Grinding: To achieve precise dimensions, tolerances, and a smooth surface finish.

- Honing: To create a fine surface texture and improve wear resistance.

- Polishing: To achieve a highly reflective or mirror-like surface.

- Hardening: To increase the hardness and durability of the roller surface through thermal or chemical processes.

- Coating: To protect against corrosion, enhance wear resistance, or improve grip.

4. Describe the process for maintaining and calibrating roller bearings.

- Inspect bearings regularly for signs of wear, damage, or lubrication issues.

- Clean and lubricate bearings as per manufacturer’s instructions.

- Check bearing alignment and adjust as necessary to ensure proper performance.

- Monitor bearing temperature and vibration levels to detect potential problems early on.

- Calibrate bearings using appropriate tools and equipment to verify accuracy and precision.

5. What are the safety precautions that must be observed when handling heavy rollers?

- Wear appropriate personal protective equipment (PPE): Hard hat, gloves, safety glasses, and hearing protection.

- Inspect rollers for damage or defects before handling.

- Use proper lifting equipment and techniques to avoid strain or injury.

- Secure rollers properly to prevent rolling or shifting during transportation or storage.

- Be aware of the surrounding environment and potential hazards (e.g., overhead obstacles, slippery surfaces).

6. Explain how to troubleshoot common problems encountered with roller conveyors.

- Jammed rollers: Check for foreign objects or misaligned rollers.

- Misaligned rollers: Adjust the roller supports or alignment bars.

- Excessive vibration: Inspect bearings, belts, and motor; balance or replace as needed.

- Slow or non-moving rollers: Check power supply, motor, or drive components.

- Product damage: Inspect rollers for damage or debris; adjust speed or padding as needed.

7. Describe the steps involved in installing a new roller on a conveyor system.

- Prepare the conveyor by cleaning and lubricating the roller supports.

- Align the new roller with the existing ones, ensuring proper spacing and parallelism.

- Secure the roller to the supports using bolts or other fasteners.

- Check the alignment and tension; adjust as necessary.

- Lubricate the new roller as per manufacturer’s instructions.

8. Explain the importance of roller hardness and how it affects roller performance.

- Harder rollers: Resist wear and deformation better, extending their lifespan.

- Softer rollers: May provide better grip and flexibility under certain operating conditions.

- Appropriate hardness selection ensures optimal performance, efficiency, and longevity of rollers.

9. Describe the different types of roller materials and their applications.

- Steel: Durable, strong, and wear-resistant for general-purpose applications.

- Rubber: Provides cushioning, noise reduction, and grip in food processing, packaging, and other industries.

- Ceramic: Resistant to corrosion, wear, and high temperatures for specialized applications.

- Plastic: Lightweight, corrosion-resistant, and suitable for food and pharmaceutical industries.

10. Explain how to calculate the load capacity of a roller bearing.

- Determine the bearing type, diameter, and housing dimensions.

- Find the load ratings for the specific bearing from the manufacturer’s specifications.

- Consider the operating conditions (e.g., speed, load, and temperature).

- Apply appropriate reduction factors based on dynamic load, misalignment, and other factors.

- Calculate the effective load capacity by adjusting the rated load capacity using the reduction factors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roller Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roller Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Roller Checker plays a vital role in maintaining the quality and productivity of an industrial production line, primarily involving the inspection and maintenance of conveyor rollers, ensuring their smooth operation. Here are the key job responsibilities you should expect as a Roller Checker:

1. Inspection and Maintenance of Conveyor Rollers

The primary duty is to inspect conveyor rollers regularly for any damage, wear, or misalignment. You will visually examine the rollers, bearings, and seals for signs of deterioration or malfunction.

- Inspect rollers for cracks, dents, or other damage.

- Monitor bearing condition, lubricate them, and replace them when necessary.

- Ensure proper alignment of rollers to prevent conveyor belt derailment or damage.

2. Troubleshooting and Repair

When issues arise with conveyor rollers, you will be responsible for diagnosing the problem and taking appropriate action. This may involve replacing damaged components, adjusting alignments, or performing minor repairs.

- Identify the cause of roller failure and implement corrective measures.

- Replace worn or damaged bearings, seals, or rollers.

- Adjust roller spacing and alignment to optimize conveyor performance.

3. Quality Control and Maintenance Documentation

An integral part of the role is ensuring that conveyor rollers meet quality standards and that maintenance procedures are followed. You will document inspections, repairs, and any issues encountered.

- Maintain accurate records of roller inspections, maintenance, and repairs.

- Document any non-conformances and take steps to prevent future occurrences.

- Ensure compliance with established quality control standards and procedures.

4. Collaboration and Communication

Effective communication and collaboration with maintenance teams, production staff, and management are crucial to the success of a Roller Checker. You will need to relay information about roller conditions, recommend maintenance schedules, and report any issues.

- Communicate roller maintenance needs and repair status to relevant personnel.

- Coordinate with production staff to minimize downtime during roller repairs.

- Participate in team meetings and provide input on conveyor maintenance strategies.

Interview Tips

Preparing thoroughly for a Roller Checker interview can significantly increase your chances of success. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Role

Take the time to research the company and the specific role you are applying for. Familiarize yourself with the company’s products, services, and industry standing. Understand the key responsibilities and requirements of the Roller Checker position.

- Visit the company’s website and read about their mission, values, and recent news.

- Check industry publications and online forums to gather insights into the company’s reputation and market position.

- Review the job description carefully and identify the skills and experience the employer is seeking.

2. Highlight Your Technical Skills and Experience

Emphasize your technical knowledge and skills related to conveyor rollers, bearings, and maintenance. Showcase your ability to identify and troubleshoot roller problems effectively. Provide specific examples from your previous experience that demonstrate your expertise.

- Quantify your accomplishments whenever possible, using numbers and metrics to demonstrate your impact.

- Highlight any certifications or training you have received in roller maintenance or related fields.

- Be prepared to discuss your understanding of different types of conveyor rollers, bearings, and lubrication systems.

3. Demonstrate Your Problem-Solving Abilities

Interviewers want to know how you approach and solve problems. Share examples of situations where you successfully diagnosed and resolved roller-related issues. Explain your thought process and the steps you took to resolve the problem.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on the outcome and how your actions contributed to the successful resolution of the problem.

- Be prepared to discuss specific tools or techniques you have used to troubleshoot and repair conveyor rollers.

4. Convey Your Attention to Detail and Quality

Roller Checkers must have a keen eye for detail and a commitment to quality. In the interview, emphasize your ability to thoroughly inspect rollers and identify even minor defects.

- Explain how you ensure accuracy and consistency in your inspections and maintenance procedures.

- Share examples of how your attention to detail has prevented or resolved potential roller issues.

- Demonstrate your understanding of quality control standards and your commitment to meeting them.

5. Showcase Your Communication and Collaboration Skills

Effective communication and collaboration are vital for a Roller Checker. Highlight your ability to communicate technical information clearly to both technical and non-technical audiences. Emphasize your teamwork skills and how you contribute to a positive work environment.

- Provide examples of how you have successfully communicated complex technical issues to stakeholders.

- Describe your experience working as part of a team and how you contribute to its success.

- Share situations where you have resolved conflicts or issues through collaboration and diplomacy.

Next Step:

Now that you’re armed with the knowledge of Roller Checker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Roller Checker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini