Are you gearing up for an interview for a Roller Engraver position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Roller Engraver and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

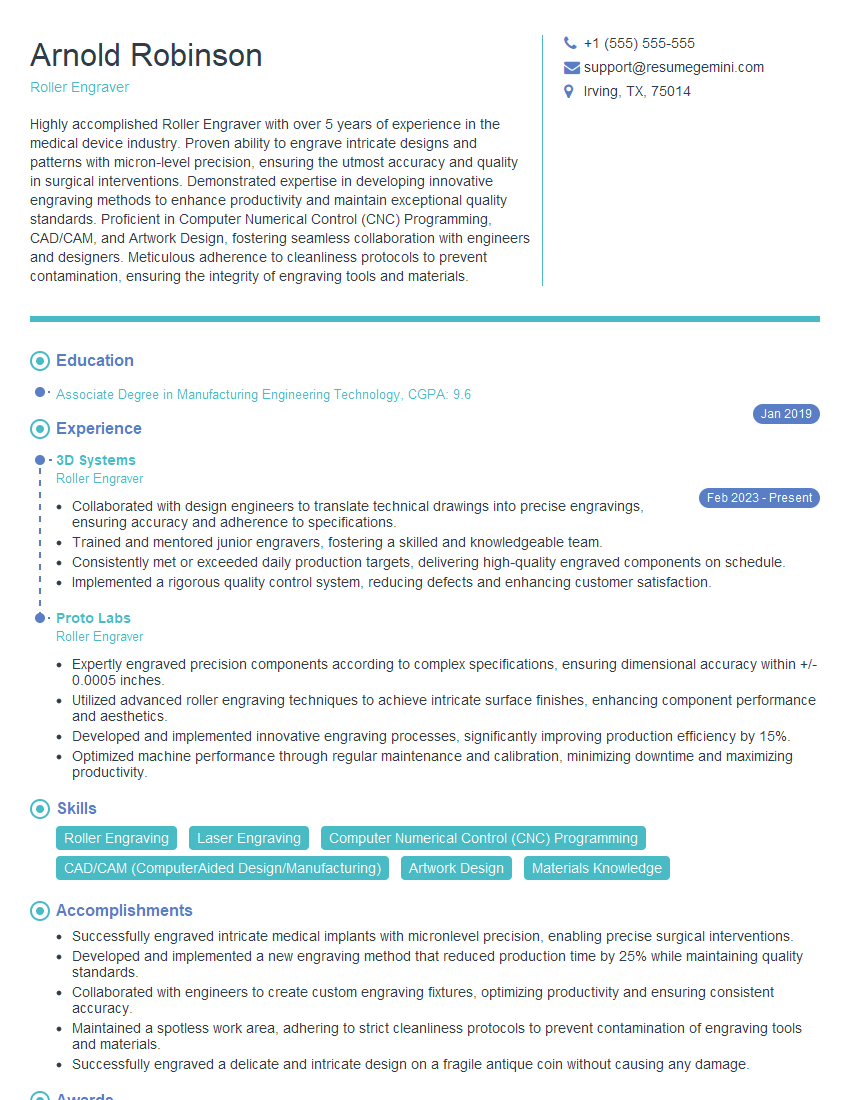

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roller Engraver

1. Explain the process of setting up and calibrating a roller engraving machine.

The process of setting up and calibrating a roller engraving machine involves several steps:

- Machine assembly: The machine is first assembled according to the manufacturer’s instructions.

- Roller installation: The engraving roller is installed on the machine and secured in place.

- Material mounting: The material to be engraved is mounted on the machine’s worktable and secured.

- Depth adjustment: The depth of the engraving is adjusted by setting the distance between the roller and the material.

- Speed and pressure settings: The engraving speed and pressure are set according to the material and the desired engraving depth.

- Test engraving: A test engraving is performed to check the machine’s settings and make any necessary adjustments.

2. How do you ensure the accuracy and precision of roller engravings?

Precision and accuracy

- Machine calibration: Regular calibration of the machine ensures that the engraving roller is precisely aligned and the material is held securely.

- Material selection: Using high-quality materials with consistent thickness helps maintain accuracy and precision.

- Proper setup: Correctly setting the engraving depth, speed, and pressure is crucial for precise results.

Consistency

- Engraving roller maintenance: Regular cleaning and maintenance of the engraving roller ensures consistent engraving quality.

- Standardized process: Following a standardized engraving process helps maintain accuracy and precision across different jobs.

- Quality control: Implementing quality control measures, such as inspection and measurement, ensures that engravings meet specifications.

3. Describe the different types of materials that can be engraved using a roller engraving machine.

A roller engraving machine can engrave a wide range of materials, including:

- Metals: Steel, aluminum, brass, copper, titanium, etc.

- Plastics: Acrylic, polycarbonate, polyethylene, PVC, etc.

- Wood: Hardwoods, softwoods, plywood, MDF, etc.

- Glass: Float glass, tempered glass, laminated glass, etc.

- Leather: Genuine leather, faux leather, suede, etc.

- Paper and cardboard: Thick paper, corrugated cardboard, etc.

4. How do you choose the correct engraving roller for a specific material and application?

Choosing the correct engraving roller depends on several factors:

- Material type: Different materials require specific engraving roller materials and hardness.

- Engraving depth: The desired engraving depth determines the type of roller and the number of passes required.

- Detail level: For intricate designs or fine details, a roller with a smaller diameter and finer teeth is preferred.

- Machine compatibility: The roller must be compatible with the machine’s specifications, such as the engraving speed and pressure.

5. What are the common maintenance procedures required for a roller engraving machine?

- Engraving roller maintenance: Cleaning and lubricating the engraving roller regularly extends its life and ensures optimal performance.

- Machine cleaning: Keeping the machine clean, including the worktable and other components, prevents debris accumulation and ensures smooth operation.

- Lubrication: Regularly lubricating moving parts, such as bearings and gears, reduces friction and wear.

- Electrical checks: Periodically checking electrical connections and wiring ensures safe operation.

- Software updates: Updating the machine’s software keeps it up-to-date with the latest features and bug fixes.

6. How do you troubleshoot common problems that occur during roller engraving?

- Poor engraving quality: Check the engraving roller for wear or damage, adjust the machine settings, or try a different roller.

- Machine malfunction: Inspect electrical connections, check for error messages, and consult the machine’s manual.

- Material issues: Ensure the material is properly mounted and free of defects.

- Software errors: Restart the software, check for updates, or contact the software provider.

- Safety issues: Always follow safety precautions, such as wearing protective gear and operating the machine in a well-ventilated area.

7. What safety precautions should be taken when using a roller engraving machine?

- Protective equipment: Wear safety glasses, gloves, and hearing protection.

- Proper ventilation: Ensure adequate ventilation to remove fumes and dust generated during engraving.

- Machine guarding: Keep the machine guarded to prevent accidental contact with moving parts.

- Electrical safety: Check electrical connections regularly and avoid operating the machine with exposed wires.

- Training: Only trained and authorized personnel should operate the engraving machine.

8. How do you stay updated with the latest advancements in roller engraving technology?

- Industry publications: Read trade magazines and journals focused on engraving and manufacturing.

- Conferences and exhibitions: Attend industry events to learn about new technologies and equipment.

- Manufacturer updates: Stay informed about software updates and new roller engraving products from machine manufacturers.

- Online resources: Utilize online forums, websites, and social media platforms to connect with other engravers and stay informed about industry developments.

9. What is your approach to achieving high-quality results in roller engraving?

- Attention to detail: Pay meticulous attention to every aspect of the engraving process, from material preparation to machine setup.

- Proper setup: Ensure the machine and engraving roller are properly calibrated and adjusted for the specific material and desired engraving depth.

- Quality materials: Use high-quality materials and engraving rollers to achieve the best possible results.

- Regular maintenance: Perform regular maintenance on the engraving machine to keep it in optimal condition.

- Continuous improvement: Stay updated with the latest techniques and technologies to continuously improve engraving quality.

10. How do you manage deadlines and prioritize tasks in a fast-paced production environment?

- Planning and scheduling: Establish a production schedule and prioritize tasks based on their importance and deadlines.

- Time management: Utilize time management techniques to allocate time effectively and meet deadlines.

- Communication: Communicate with team members and supervisors to stay informed about schedule changes and task dependencies.

- Flexibility: Be prepared to adjust priorities and adapt to changing circumstances while maintaining focus on meeting deadlines.

- Delegation: Delegate tasks to team members when appropriate to distribute workload and ensure timely completion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roller Engraver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roller Engraver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Roller Engraver is responsible for engraving designs and patterns onto cylindrical surfaces, using a specialized machine. Their primary duties include:

1. Engraving Cylinders

Using a roller engraving machine, create intricate designs and patterns on cylindrical surfaces, such as printing rollers, metal rollers, and other cylindrical components.

- Operate the engraving machine with precision and accuracy to achieve desired results.

- Set up and adjust the machine for different engraving tasks.

2. Inspecting and Maintaining Equipment

Regularly inspect and maintain the engraving machine, ensuring it is in good working condition.

- Identify and resolve any mechanical or electrical issues with the machine.

- Perform routine maintenance tasks, such as cleaning, lubrication, and calibration.

3. Calibrating and Adjusting the Machine

Ensure the engraving machine is calibrated and adjusted correctly to produce high-quality engravings.

- Adjust the engraving depth, speed, and pressure to achieve the desired results.

- Use precision measuring tools to verify the accuracy of the engravings.

4. Monitoring the Engraving Process

Monitor the engraving process closely to ensure it is proceeding smoothly and according to specifications.

- Identify any deviations from the desired outcome and make necessary adjustments.

- Ensure that the engravings meet the required quality standards.

Interview Tips

To prepare for a Roller Engraver interview, candidates should focus on demonstrating their technical skills, experience with engraving machines, and attention to detail. Here are some tips:

1. Research the Company and Position

Take the time to research the company and the specific role you are applying for. This will give you a better understanding of the company’s culture, values, and expectations.

- Visit the company’s website and social media pages.

- Read industry news and articles related to roller engraving.

2. Practice Your Skills

If possible, practice your roller engraving skills before the interview. This will help you feel more confident and demonstrate your abilities to the interviewer.

- If you have access to an engraving machine, practice creating different designs and patterns.

- If you do not have access to an engraving machine, try practicing on a piece of paper or cardboard.

3. Prepare Examples of Your Work

Bring examples of your previous work to the interview. This could include photos of your engravings, samples of your work, or a portfolio.

- Be prepared to discuss the techniques you used to create your engravings.

- Explain how your engravings meet the required quality standards.

4. Be Enthusiastic and Professional

Be enthusiastic about the opportunity to work as a Roller Engraver. Demonstrate your passion for the craft and your commitment to producing high-quality work.

- Dress professionally and arrive on time for the interview.

- Be polite and respectful to the interviewer.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Roller Engraver role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.