Are you gearing up for an interview for a Roller Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Roller Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

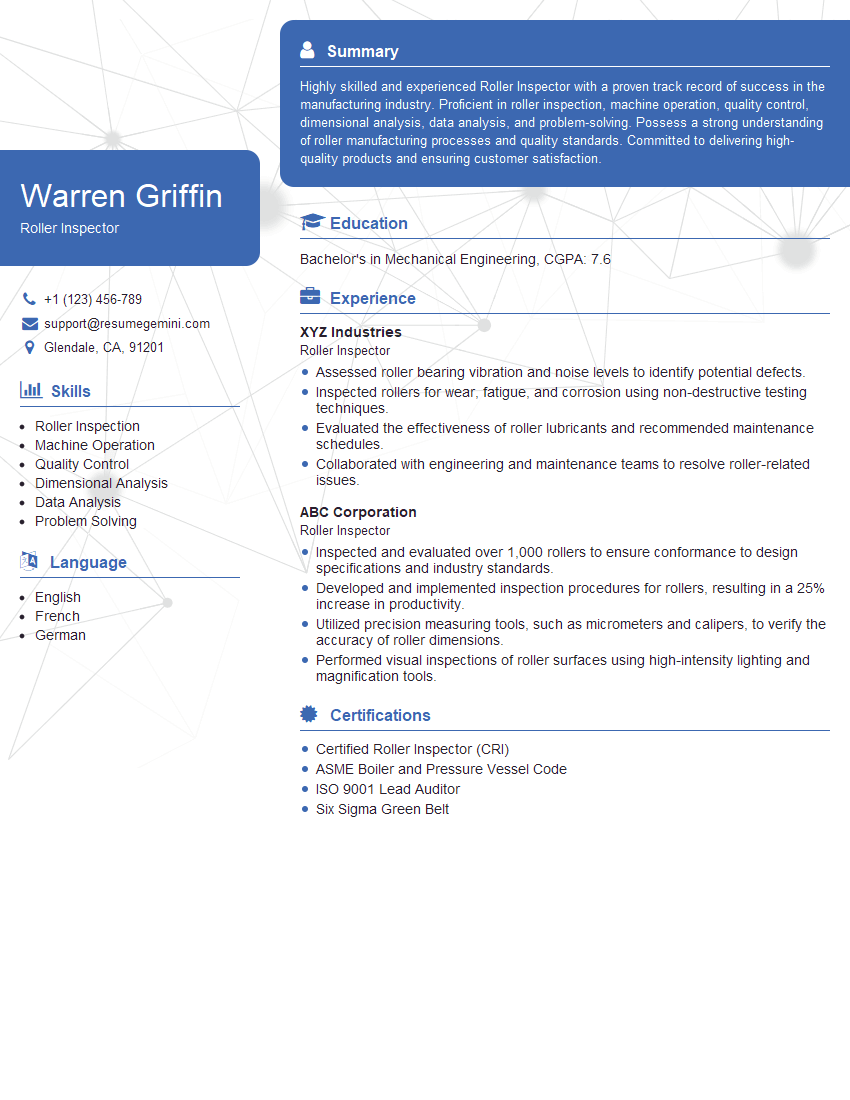

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roller Inspector

1. Describe the key responsibilities of a Roller Inspector?

- Inspect and evaluate the condition of rollers, bearings, and other components of conveyor systems.

- Identify and report any defects, wear, or damage to ensure the smooth operation of the system.

- Monitor and maintain lubrication schedules to prevent premature failure.

- Keep accurate records of inspections and repairs.

- Work closely with maintenance teams to resolve issues and improve roller performance.

2. What are the different types of rollers used in conveyor systems and their applications?

- Gravity rollers: Used in non-powered conveyors, rely on gravity to move items.

- Powered rollers: Incorporate motors or drives to move items along the conveyor.

- Conveyor belt rollers: Support and guide conveyor belts.

- Chain rollers: Used in chain-driven conveyors.

- Specialty rollers: Designed for specific applications, such as high-temperature or corrosive environments.

3. Explain the process of roller inspection and what factors you consider?

- Visual inspection: Examine rollers for cracks, wear, misalignment, and other defects.

- Dimensional inspection: Measure roller diameters, lengths, and other dimensions to ensure they meet specifications.

- Load testing: Apply loads to rollers to assess their strength and durability.

- Bearing inspection: Check bearings for lubrication, wear, and any signs of damage.

- Noise and vibration analysis: Listen for excessive noise or vibrations that indicate potential problems.

4. What are the common causes of roller failure, and how can they be prevented?

- Wear and tear: Regular use and friction can lead to roller surface degradation.

- Lubrication issues: Insufficient lubrication causes increased friction and bearing failure.

- Misalignment: Improper alignment of rollers can cause uneven wear and premature failure.

- Overloading: Exceeding the rated capacity of rollers can lead to structural damage.

- Corrosion: Exposure to moisture, chemicals, or harsh environments can cause roller corrosion.

5. Describe the different types of non-destructive testing (NDT) methods used for roller inspection?

- Ultrasonic testing: Uses high-frequency sound waves to detect internal defects.

- Radiographic testing (X-ray): Penetrates materials to reveal hidden cracks or voids.

- Eddy current testing: Induces electrical currents to identify surface and subsurface defects.

- Magnetic particle testing: Magnetizes the roller to detect surface cracks.

- Penetrant testing: Penetrates surface imperfections to make them visible under UV light.

6. How do you ensure the accuracy and reliability of your roller inspections?

- Regular calibration of inspection equipment: Ensure accuracy and compliance with standards.

- Following standardized inspection procedures: Minimize human error and ensure consistency.

- Continuous training and certification: Stay abreast of the latest inspection techniques and best practices.

- Maintaining detailed inspection records: Provide evidence of thorough inspections and track roller condition over time.

- Seeking external audits or certifications: Validate the quality and reliability of inspection practices.

7. How do you prioritize roller maintenance and repairs to minimize downtime?

- Risk assessment: Evaluate the severity of roller defects and the potential impact on system operation.

- Scheduling based on inspection results: Plan maintenance and repairs based on the urgency of identified issues.

- Prioritizing critical rollers: Focus on maintaining rollers that are essential for the smooth operation of the system.

- Maintaining spare parts inventory: Ensure availability of replacement rollers to minimize downtime during repairs.

- Working closely with maintenance teams: Coordinate with maintenance personnel to ensure timely repairs and avoid production delays.

8. What software or tools do you use for roller inspection and data management?

- Inspection management software: Track inspections, generate reports, and manage maintenance schedules.

- Roller inspection apps: Mobile applications that streamline data collection and defect reporting.

- Computer-aided design (CAD) software: Visualize roller designs and identify potential failure points.

- Data analysis tools: Analyze inspection data to identify trends and predict future roller performance.

- Cloud-based platforms: Store and share inspection records securely and collaborate with remote teams.

9. Describe your experience in working with automated roller inspection systems?

- Implementation and configuration: Assisted in setting up and calibrating automated inspection systems.

- Data analysis and interpretation: Analyzed data from automated inspections to identify defects and assess roller condition.

- System maintenance and troubleshooting: Ensured proper functioning of automated systems and resolved technical issues.

- Integration with other systems: Integrated automated inspection systems with maintenance management and data analysis platforms.

- Continuous improvement: Monitored system performance and identified areas for optimization.

10. How do you stay updated on the latest advancements in roller inspection technology?

- Attend industry conferences and webinars: Stay informed about new inspection techniques and technologies.

- Read technical publications: Review journals and articles on advancements in roller inspection.

- Connect with industry experts: Interact with professionals and learn about their experiences and best practices.

- Participate in training programs: Enhance skills and knowledge through specialized training and certification courses.

- Research and explore new technologies: Stay curious and investigate emerging inspection technologies that can improve efficiency and accuracy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roller Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roller Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roller Inspectors are responsible for ensuring that rollers meet the required specifications and quality standards. Their key job responsibilities include:

1. Inspecting Rollers

Inspecting rollers for defects, such as cracks, dents, or other imperfections.

- Using a variety of tools and equipment to measure and test rollers.

- Identifying and documenting any defects found.

2. Maintaining Inspection Records

Maintaining accurate records of all inspections performed.

- Documenting the results of inspections, including any defects found.

- Keeping records of all repairs and maintenance performed on rollers.

3. Troubleshooting and Problem Solving

Troubleshooting and resolving any issues that arise with rollers.

- Identifying the root cause of problems.

- Developing and implementing solutions to resolve problems.

4. Communicating Inspection Results

Communicating the results of inspections to management and other stakeholders.

- Preparing and presenting reports on inspection findings.

- Discussing inspection results with management and other stakeholders.

Interview Tips

To ace the interview for a Roller Inspector position, it is important to:

1. Research the Company and Position

Before the interview, research the company and the specific Roller Inspector position. This will help you understand the company’s culture, values, and expectations for the role.

- Visit the company’s website to learn about their mission, values, and products or services.

- Review the job description carefully to understand the specific responsibilities and requirements of the position.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the actual interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering questions about your motivation for applying for the position.

3. Dress Professionally

First impressions matter, so dress professionally for the interview. This shows that you are taking the interview seriously and that you respect the interviewer’s time.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

4. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic and positive about the position. Show the interviewer that you are excited about the opportunity to work for the company.

- Smile and make eye contact with the interviewer.

- Be enthusiastic when answering questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roller Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.