Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Roller Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Roller Machine Operator so you can tailor your answers to impress potential employers.

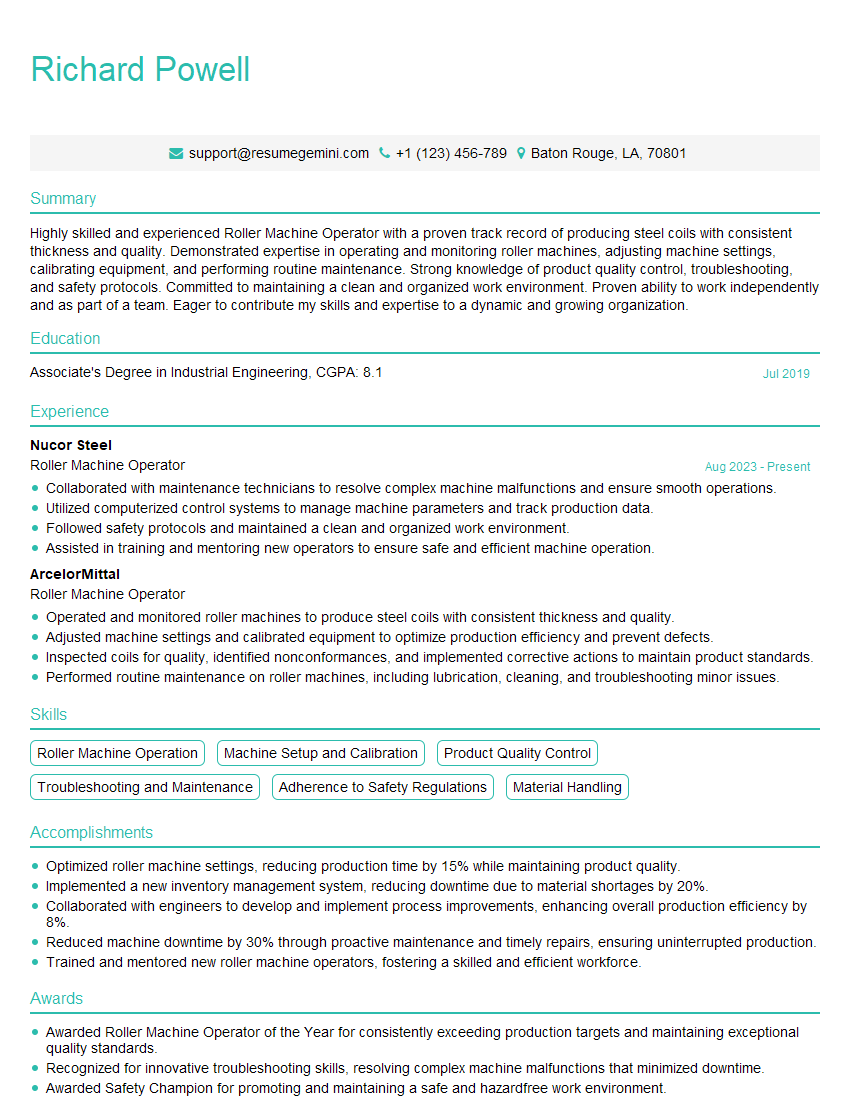

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roller Machine Operator

1. What are the key responsibilities of a Roller Machine Operator?

- Operate and maintain roller machines to produce various products, such as sheets, tubes, or other shaped items

- Control the speed, temperature, and pressure of the machine to achieve desired product specifications

- Monitor the machine for any signs of malfunction and make necessary adjustments

- Perform routine maintenance and troubleshoot any issues that arise

- Follow safety protocols and maintain a clean and organized work area

2. What types of materials can be processed using a roller machine?

Metals

- Steel

- Aluminum

- Copper

- Brass

Plastics

- Polyethylene

- Polypropylene

- Polyvinyl chloride

- Polystyrene

Other materials

- Paper

- Rubber

- Textiles

3. What are the different types of roller machines?

Two-high roller mill

Used for rolling flat products, such as sheets and plates

Four-high roller mill

Used for rolling thicker products, such as bars and rods

Cluster mill

Used for rolling wire and other small-diameter products

Sendzimir mill

Used for rolling thin, high-strength materials, such as stainless steel

4. What are the key factors that affect the quality of the rolled product?

Material properties

The type of material being rolled, its thickness, and its strength

Machine settings

The speed, temperature, and pressure of the rolling mill

Operator skill

The experience and expertise of the operator

Environmental conditions

The temperature and humidity of the surrounding environment

5. How do you ensure that the rolled product meets the required specifications?

Calibrating the machine

Ensuring that the machine is set up correctly and is operating within tolerance

Monitoring the process

Observing the machine and the product during the rolling process to identify any deviations

Measuring the product

Using precision measuring tools to verify that the product meets the required dimensions and tolerances

Making adjustments

Adjusting the machine settings or the process parameters to correct any deviations

6. What are the common problems that can occur during the rolling process?

Surface defects

Scratches, dents, or cracks on the surface of the product

Dimensional errors

The product is not the correct thickness, width, or length

Mechanical defects

The product is not strong enough or does not meet the required mechanical properties

Machine breakdowns

The rolling mill breaks down due to mechanical or electrical problems

7. How do you troubleshoot and resolve problems that occur during the rolling process?

Identify the problem

Observe the machine and the product to determine the cause of the problem

Determine the root cause

Analyze the problem to determine the underlying cause

Develop a solution

Identify and implement a solution to correct the problem

Verify the solution

Test the solution to ensure that the problem has been resolved

8. What are the safety precautions that must be followed when operating a roller machine?

Wear appropriate safety gear

Such as safety glasses, gloves, and earplugs

Be aware of the pinch points

Where the rollers meet

Keep your hands away from the rollers

While the machine is operating

Do not operate the machine if you are tired or under the influence of drugs or alcohol

Follow all lockout/tagout procedures

Before performing any maintenance or repairs

9. What are your strengths as a Roller Machine Operator?

Experience

I have several years of experience operating roller machines in a variety of settings

Skills

I am proficient in all aspects of roller machine operation, including setup, calibration, operation, and troubleshooting

Safety

I am committed to safety and have a strong understanding of all safety protocols

Teamwork

I am a team player and I am always willing to help others

10. What are your career goals?

Short-term goals

My short-term goals are to become a proficient Roller Machine Operator and to learn as much as I can about the industry

Long-term goals

My long-term goals are to become a Supervisor or Manager in the rolling mill industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roller Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roller Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Roller Machine Operator

Roller Machine Operators play a vital role in manufacturing industries, ensuring the efficient operation and maintenance of roller machines.

1. Machine Operation

Operate and monitor roller machines to produce various products, such as paper, metal, and textiles.

- Adjust machine settings, such as speed, temperature, and pressure, to achieve optimal production.

- Monitor machine performance and make necessary adjustments to ensure smooth operation.

2. Material Handling

Load and unload materials onto the roller machine and inspect them for defects.

- Operate material handling equipment, such as forklifts and conveyors.

- Maintain a clean and organized work area.

3. Maintenance and Troubleshooting

Perform routine maintenance on roller machines, including lubrication, cleaning, and repairs.

- Identify and troubleshoot machine malfunctions and take corrective action.

- Keep detailed records of maintenance and repairs.

4. Quality Control

Inspect finished products to ensure they meet quality standards.

- Use measuring tools and gauges to verify product dimensions and tolerances.

- Identify and report any defects or non-conformance.

Interview Preparation Tips

To ace your Roller Machine Operator interview, follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends.

- This will demonstrate your interest and knowledge of the field.

- Use websites, news articles, and company financial reports for research.

2. Practice Your Answers

Prepare for common interview questions and practice your responses.

- Focus on emphasizing your skills, experience, and why you’re the best fit for the job.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to match the job description.

- Showcase your experience in operating roller machines, troubleshooting, and quality control.

- Quantify your accomplishments using specific numbers and metrics.

4. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving punctually for the interview.

- Your attire should be clean, pressed, and reflect the company’s culture.

- Plan your route and transportation in advance to avoid delays.

5. Ask Thoughtful Questions

Ask thoughtful questions at the end of the interview to show your engagement and interest in the role.

- Inquire about career growth opportunities, training programs, or industry trends.

- This shows you’re eager to learn and advance within the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roller Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.