Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roller Printing Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

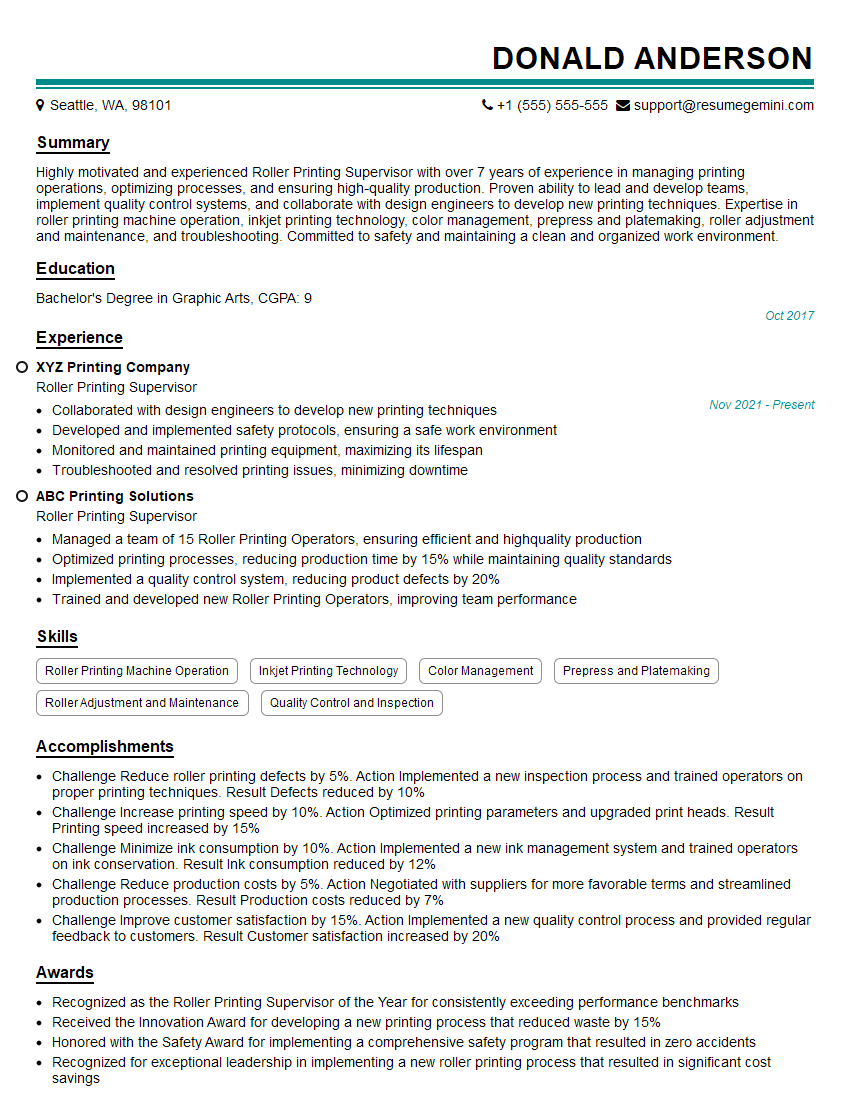

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roller Printing Supervisor

1. Explain the different types of roller printing techniques and their applications?

– Gravure printing: Uses a metal cylinder with etched cells to transfer ink onto the substrate. This technique is known for its ability to produce high-quality images with fine details and is commonly used for printing on packaging, fabrics, and wallpapers.

– Flexographic printing: Similar to gravure printing, but uses a flexible rubber or photopolymer plate. It is suitable for printing on a wide range of materials, including paper, plastic, and metal, and is often used for packaging and industrial applications.

– Offset printing: Involves transferring ink from a metal plate to a rubber roller, which then transfers the ink onto the substrate. This method allows for precise color reproduction and is commonly used for high-quality print jobs such as books, magazines, and brochures.

2. Describe the key factors to consider when selecting inks for roller printing?

- Compatibility with the printing process: Inks must be compatible with the specific printing technique and equipment used.

- Adhesion to the substrate: Inks must adhere well to the material being printed on, considering factors such as porosity and surface texture.

- Drying time and curing process: Inks must have appropriate drying or curing characteristics to ensure optimal print quality and durability.

- Color accuracy and consistency: Inks must produce the desired colors accurately and consistently throughout the printing run.

3. Explain the role of rollers in the roller printing process and describe the different types of rollers used?

Rollers play a crucial role in roller printing, performing various functions such as:

– Applying ink to the printing plate: Ink rollers transfer ink from the ink reservoir onto the printing plate.

– Transferring ink from the printing plate to the substrate: Impression rollers press the substrate against the printing plate, transferring the inked image.

– Controlling ink flow and distribution: Distribution rollers ensure even ink distribution across the printing plate.

– Cleaning the printing plate: Doctor blades or cleaning rollers remove excess ink from the printing plate.

Types of rollers:

- Ink rollers: Made of rubber or polyurethane, they are designed to pick up and transfer ink efficiently.

- Impression rollers: Usually made of rubber, they are designed to exert pressure and transfer the ink to the substrate.

- Distribution rollers: Made of rubber or metal, they distribute ink evenly across the printing plate.

- Doctor blades: Thin, sharp blades made of metal or ceramic, they scrape off excess ink from the printing plate.

4. Describe the quality control measures you would implement to ensure the production of high-quality printed products?

- Pre-press checks: Inspecting artwork, printing plates, and inks for accuracy and quality.

- In-process monitoring: Regularly checking print quality, ink levels, and equipment performance throughout the printing run.

- Post-press inspection: Verifying print quality, color accuracy, and overall product appearance before dispatch.

- Color calibration and profiling: Ensuring color consistency and accuracy across different printing machines and materials.

- Regular maintenance and calibration of equipment: Preventing equipment malfunctions that could affect print quality.

5. What are the common troubleshooting techniques for roller printing issues such as ink smudging, poor registration, and color variations?

- Ink smudging: Inspecting rollers for wear or damage, adjusting ink viscosity or flow, increasing drying time.

- Poor registration: Checking plate alignment, ensuring proper roller pressure and substrate tension, inspecting for worn or damaged parts.

- Color variations: Verifying ink compatibility and consistency, checking color plates and registration, calibrating printing equipment.

6. Describe the different safety precautions that must be observed when operating roller printing equipment?

- Proper guarding of machinery: Ensuring that moving parts are covered to prevent accidents.

- Safe handling of chemicals: Using gloves, protective clothing, and proper ventilation when handling inks and solvents.

- Machine lockout/tagout procedures: Following established protocols when servicing or repairing equipment.

- Regular maintenance and inspections: Identifying potential hazards and taking preventive measures.

- Training and supervision of operators: Ensuring operators are trained in safe operating procedures and supervised when necessary.

7. Discuss the importance of maintaining optimal humidity and temperature levels in the printing environment and how you would ensure proper conditions?

Maintaining optimal humidity and temperature levels in the printing environment is crucial for several reasons:

– Paper quality: Humidity affects paper moisture content, impacting ink absorption and print quality.

– Ink viscosity: Temperature affects ink viscosity, influencing its flow and transfer properties.

– Equipment performance: Humidity and temperature can impact the performance of printing equipment, such as ink rollers and dryers.

To ensure proper conditions, I would:

– Monitor humidity and temperature levels using hygrometers and thermometers.

– Use humidifiers or dehumidifiers as needed to maintain optimal ranges.

– Install temperature control systems to maintain stable temperatures.

– Regularly inspect and maintain equipment to ensure optimal performance in varying conditions.

8. Explain how you would optimize production schedules and minimize downtime to maximize productivity and efficiency?

- Efficient planning and scheduling: Creating production schedules that minimize idle time and optimize machine utilization.

- Preventive maintenance: Regularly servicing and maintaining equipment to prevent unexpected breakdowns.

- Cross-training of operators: Training operators on multiple tasks to cover for absences or handle surges in workload.

- Continuous improvement: Identifying and implementing process improvements to reduce waste and increase efficiency.

- Effective communication: Establishing clear communication channels to ensure timely response to any issues that arise.

9. Describe your experience in managing a team of printing operators and how you would motivate and develop your team?

Managing a team of printing operators involves:

– Providing clear instructions and ensuring operators understand their roles and responsibilities.

– Monitoring performance, providing feedback, and recognizing achievements.

– Creating a positive and supportive work environment to motivate and engage the team.

– Identifying training and development opportunities to enhance their skills and knowledge.

Motivating and developing my team, I would:

– Set clear expectations and provide regular feedback to help them understand their progress.

– Empower them to take ownership of their work and make decisions within their scope.

– Recognize and reward their efforts to create a culture of appreciation and motivation.

– Foster a learning environment and encourage their professional growth and development.

10. Explain your understanding of sustainable printing practices and how you would implement them within the printing operations?

- Using environmentally friendly inks and materials: Opting for inks and materials with low VOCs and biodegradable properties.

- Reducing paper waste: Implementing digital proofing and optimizing print runs to minimize paper consumption.

- Efficient energy management: Utilizing energy-efficient equipment, optimizing lighting, and implementing power-saving measures.

- Proper waste disposal: Establishing proper waste disposal procedures for inks, solvents, and paper waste.

- Educating and engaging employees: Promoting awareness among employees about sustainable practices and their role in implementing them.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roller Printing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roller Printing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roller Printing Supervisors are responsible for overseeing and managing the production of printed materials using roller printing machines. They work closely with other departments to ensure that the printing process is running smoothly and that the quality of the printed products meets customer specifications.

1. Supervise and coordinate printing operations

Supervisors are responsible for planning and coordinating all aspects of the printing process, including:

- Scheduling printing jobs

- Assigning tasks to employees

- Monitoring the progress of printing jobs

- Ensuring that all printing jobs are completed on time and to the required quality standards

2. Maintain and troubleshoot printing equipment

Supervisors are also responsible for maintaining and troubleshooting printing equipment. This includes:

- Performing routine maintenance on printing machines

- Troubleshooting and repairing printing machines

- Ordering and installing new printing equipment

3. Manage employee performance

In addition to supervising the printing process, Supervisors are also responsible for managing employee performance. This includes:

- Hiring and training new employees

- Evaluating employee performance

- Providing feedback and coaching to employees

- Disciplining employees when necessary

4. Comply with safety regulations

Supervisors are also responsible for ensuring that all employees comply with safety regulations. This includes:

- Enforcing safety rules and regulations

- Conducting safety training for employees

- Investigating safety incidents

Interview Tips

Preparing for a job interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Do your research

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about your accomplishments in detail. Use specific examples to illustrate your skills and how you have used them to achieve success in your previous roles.

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic and positive about their work. Be sure to convey your passion for the printing industry and your desire to learn and grow in this role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roller Printing Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!