Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roller Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

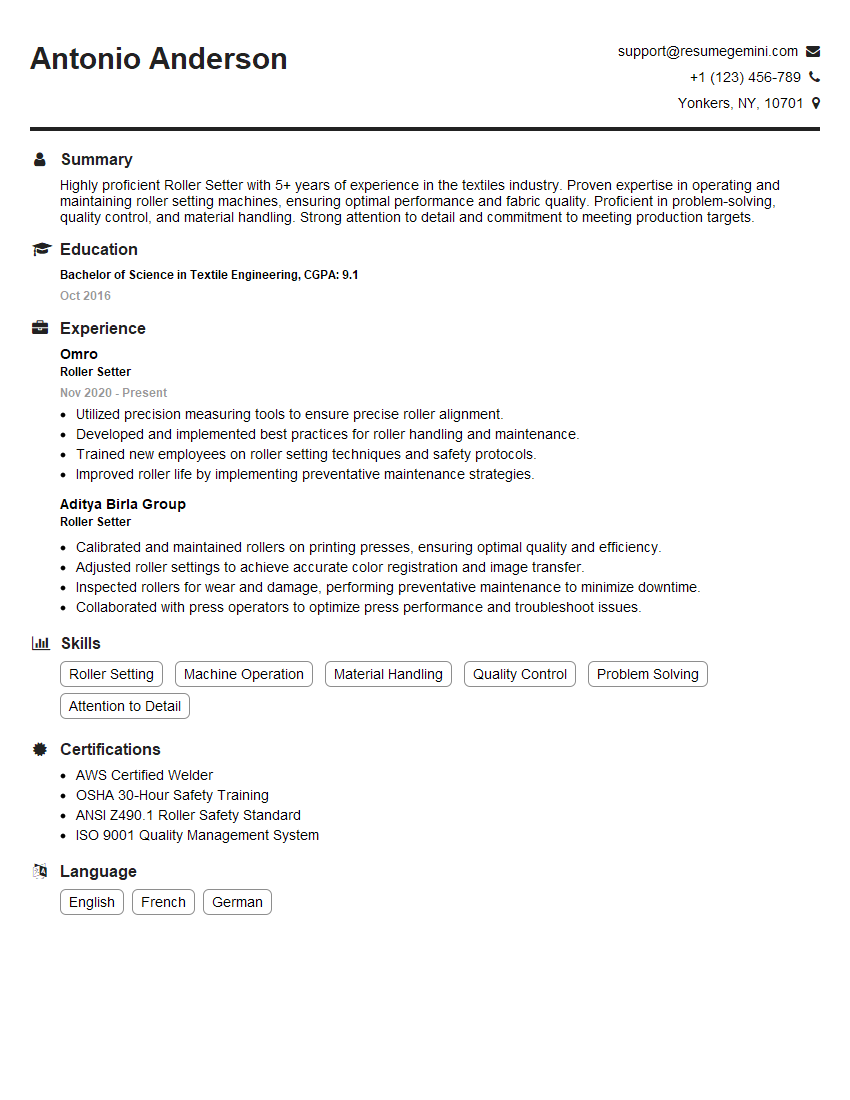

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roller Setter

1. What type of rollers do you use for different materials?

The type of rollers I use for different materials depends on the material’s properties and the desired finish. For example, for soft materials like aluminum, I might use soft rubber rollers to avoid scratching the surface. For harder materials like steel, I might use steel or carbide rollers to achieve a more aggressive finish.

2. What are the key factors to consider when setting up a roller for a specific application?

Factors to Consider

- Material type and thickness

- Desired finish

- Roller diameter and speed

- Pressure applied

Impact of Roller Setting

- Wrong roller type, diameter or speed can damage the material or affect the finish

- Incorrect pressure can cause roller slippage or indentation in the material

3. How do you troubleshoot common roller-related problems, such as chattering, slipping, or uneven pressure?

- Chattering: Ensure rollers are aligned and balanced, adjust roller speed, or use anti-vibration pads.

- Slipping: Check roller tension, clean rollers, or apply a non-slip coating.

- Uneven pressure: Adjust roller mounting brackets, check for worn or damaged rollers, or use a pressure gauge.

4. What are the safety precautions that must be taken when operating a roller machine?

- Wear appropriate PPE (gloves, safety glasses, earplugs)

- Securely fasten materials to prevent slippage

- Keep hands and loose clothing away from moving parts

- Inspect equipment regularly and report any potential hazards

- Follow proper lockout/tagout procedures during maintenance

5. How do you maintain and inspect rollers to ensure optimal performance?

- Regular cleaning: Remove debris and dirt to prevent damage

- Lubrication: Follow manufacturer’s instructions to ensure smooth operation

- Inspection: Check for cracks, wear, or damage, and replace as needed

- Alignment and tension: Adjust as necessary to prevent premature wear and maintain precision

6. What types of materials can be rolled, and what are the different finishes that can be achieved?

- Materials: Metals (steel, aluminum, copper), plastics, fabrics, paper

- Finishes: Smooth, textured, patterned, embossed, polished, brushed

7. What are the different types of roller machines available, and what are their advantages and disadvantages?

Types of Roller Machines

- Sheet rollers: For flattening and shaping sheet metal

- Tube rollers: For bending and shaping tubes

- Plate rollers: For rolling and forming thick metal plates

- Die rollers: For creating intricate shapes and patterns

Advantages and Disadvantages

- Advantages: High precision, versatility, automation capabilities

- Disadvantages: Can be expensive, require skilled operators, maintenance intensive

8. What are the latest advancements in roller technology, and how are they impacting the industry?

- Automated roller machines: Reduced labor costs, increased productivity

- Computer-controlled rollers: Enhanced precision and accuracy

- Advanced materials for rollers: Longer lifespan, improved performance

- Laser-guided rollers: Automated alignment and position control

9. How do you stay up-to-date on the latest roller technology and best practices?

- Attend industry conferences and workshops

- Read trade publications and technical articles

- Network with other roller professionals

- Consult with manufacturers and suppliers

10. Describe a challenging roller project you worked on, and how you successfully overcame it.

In a recent project, I encountered a complex design that required rolling thick steel plates into a curved shape. Due to the material’s thickness, we had to use a specialized roller machine and carefully adjust the pressure and speed to avoid cracking or deformation. Furthermore, we implemented a multi-pass rolling process to achieve the desired curvature gradually. By meticulously following these steps, we successfully completed the project, meeting the client’s specifications and expectations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roller Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roller Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Roller Setter, also known as a Roll Designer, is a highly skilled professional responsible for designing, fabricating, and setting rollers used in various industrial processes. The primary role revolves around creating high-precision rollers that ensure efficient performance and accuracy in production lines. Let’s delve into the key responsibilities:

1. Design and Development

Roller Setters are entrusted with the task of designing and developing rollers based on specific requirements and specifications. This involves understanding customer needs, calculating dimensions, selecting appropriate materials, and creating technical drawings. Their expertise in roller design ensures optimal functionality and durability.

- Collaborate with engineers and designers to determine roller specifications.

- Utilize CAD software to create precise roller designs.

- Conduct stress and performance simulations to optimize roller design.

2. Fabrication and Manufacturing

Once the design is finalized, Roller Setters meticulously fabricate rollers using specialized machinery and tooling. They oversee the entire manufacturing process, ensuring adherence to quality standards and precise specifications. Their hands-on skills and in-depth understanding of materials and processes are crucial in producing high-quality rollers.

- Select and source appropriate materials for roller construction.

- Operate machines such as lathes, grinders, and milling machines to shape and finish rollers.

- Apply coatings and treatments to enhance roller durability and performance.

3. Setting and Installation

Roller Setters play a vital role in setting and installing rollers into production equipment. They align and adjust rollers with meticulous precision to ensure smooth operation and optimal performance. Their expertise extends to troubleshooting and resolving any issues that may arise during installation.

- Install rollers onto equipment according to established procedures.

- Align and adjust rollers to achieve desired contact pressure and speed.

- Ensure proper lubrication and maintenance of rollers after installation.

4. Maintenance and Repairs

Regular maintenance and repairs are essential for ensuring optimal roller performance. Roller Setters inspect rollers periodically to identify and address any issues. They conduct repairs and replacements as needed, applying their knowledge of roller design and fabrication to restore roller functionality.

- Inspect rollers for wear, damage, or misalignment.

- Perform repairs such as grinding, honing, or resurfacing rollers.

- Replace rollers when necessary to maintain production efficiency.

Interview Tips

Preparing thoroughly for a Roller Setter interview is crucial to showcasing your skills and expertise. Here are some tips to help you ace the interview:

1. Research and Practice

Before the interview, research the company and the specific industry you’re applying for. Practice answering common interview questions about your experience in roller design, fabrication, and setting. This preparation will demonstrate your knowledge and enthusiasm for the role.

- Study industry publications and websites to stay updated on the latest roller technologies.

- Practice your answers to questions related to your ability to design, fabricate, and set rollers.

2. Highlight Your Skills

During the interview, emphasize your core competencies and technical expertise relevant to the Roller Setter position. Showcase your skills in design software, manufacturing techniques, and roller installation procedures. Quantify your accomplishments and provide specific examples of your contributions to previous projects.

- Quantify your experience in roller design, fabrication, and setting using specific examples.

- Discuss your expertise in using CAD software and your understanding of roller materials and manufacturing processes.

3. Demonstrate Your Passion

Conveying your passion for roller setting will set you apart from other candidates. Discuss your interest in the industry and your eagerness to contribute your knowledge and skills to the organization. Showcasing your enthusiasm for the role will make a positive impression on the interviewer.

- Explain your passion for roller setting and why you are excited about the opportunity.

- Share examples of your involvement in industry events or projects related to roller technology.

4. Ask Questions

At the end of the interview, don’t hesitate to ask questions about the company, the role, and the industry. This demonstrates your interest and engagement in the position. Asking well-informed questions also allows you to gather more information to help you make a decision about whether the opportunity is the right fit for you.

- Ask about the company’s growth plans and how the Roller Setter role contributes to those plans.

- Inquire about the company’s commitment to training and professional development opportunities.

Next Step:

Now that you’re armed with the knowledge of Roller Setter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Roller Setter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini