Are you gearing up for a career in Roller Varnisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Roller Varnisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

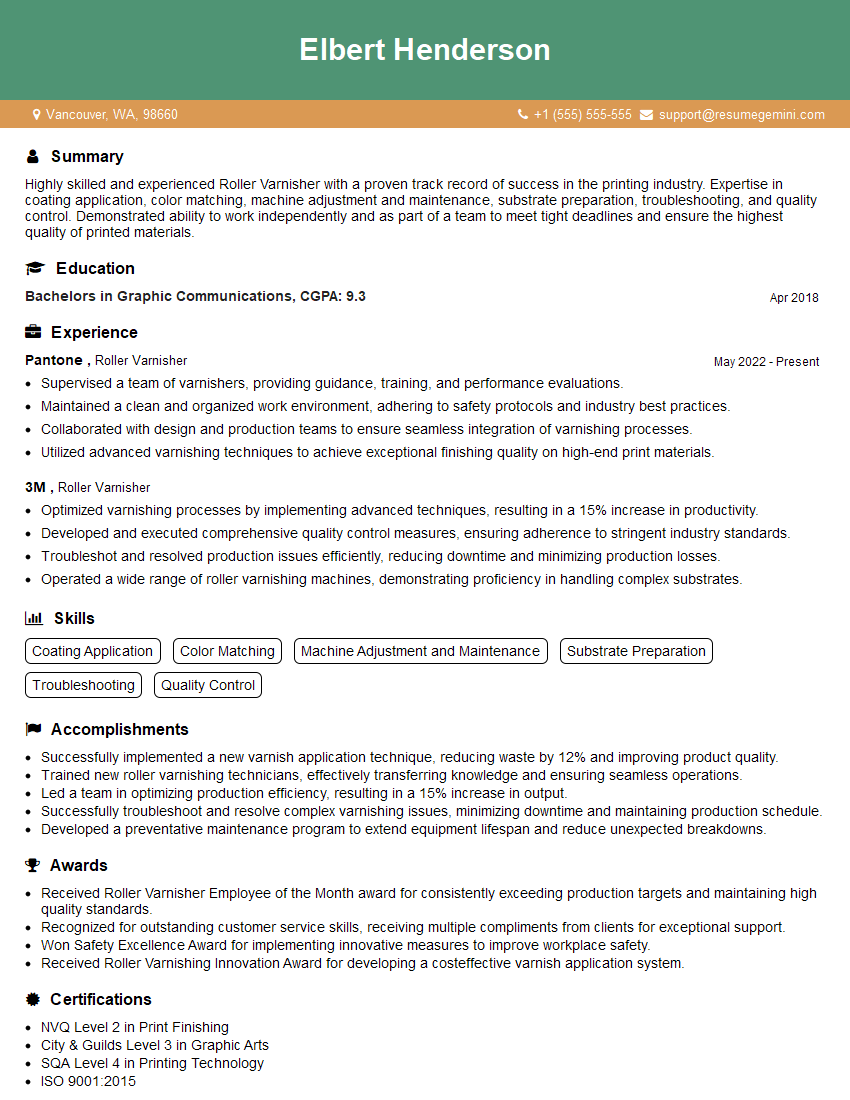

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roller Varnisher

1. What are the different types of varnishes used in roller varnishing?

- Water-based varnishes: These are the most common type of varnish used in roller varnishing. They are easy to apply and dry quickly, and they produce a clear, glossy finish.

- Solvent-based varnishes: These varnishes are made with a solvent, such as alcohol or mineral spirits. They are more durable than water-based varnishes, but they can be more difficult to apply and they can take longer to dry.

- UV-curable varnishes: These varnishes are cured by exposure to ultraviolet light. They are very durable and they can produce a high-gloss finish.

2. What are the different factors that can affect the quality of a roller varnish finish?

of the answer

- The type of varnish used: The type of varnish used will affect the durability, gloss, and clarity of the finish.

- The thickness of the varnish film: The thickness of the varnish film will affect the durability and gloss of the finish. A thicker film will be more durable, but it may also be more glossy.

- The speed of the roller: The speed of the roller will affect the thickness of the varnish film. A faster roller will produce a thinner film, while a slower roller will produce a thicker film.

- The temperature of the varnish: The temperature of the varnish will affect the flow of the varnish and the thickness of the film. A warmer varnish will flow more easily and produce a thinner film, while a cooler varnish will flow less easily and produce a thicker film.

Subheading of the answer

- The condition of the roller: The condition of the roller will affect the quality of the finish. A worn roller will produce a less even finish than a new roller.

- The condition of the substrate: The condition of the substrate will affect the adhesion of the varnish. A smooth, clean substrate will produce a better finish than a rough, dirty substrate.

3. How do you troubleshoot common problems that can occur during roller varnishing?

- Bubbles in the varnish: This can be caused by air being trapped in the varnish or by the varnish being applied too quickly. To fix this, try degassing the varnish before applying it and slowing down the roller speed.

- Wrinkling in the varnish: This can be caused by the varnish being applied too thickly or by the substrate being too smooth. To fix this, try thinning the varnish or sanding the substrate to create a rougher surface.

- Chipping in the varnish: This can be caused by the varnish being too brittle or by the substrate being too flexible. To fix this, try using a more flexible varnish or a less flexible substrate.

4. What are some of the safety precautions that should be taken when working with varnishes?

- Varnishes can be flammable, so it is important to keep them away from heat and open flames.

- Varnishes can also be toxic, so it is important to wear gloves, a mask, and eye protection when working with them.

- Varnishes can also cause skin irritation, so it is important to wash your hands thoroughly after working with them.

5. What are the latest trends in roller varnishing technology?

- The use of UV-curable varnishes is becoming increasingly popular because they offer a number of advantages over traditional varnishes. UV-curable varnishes are more durable, they can produce a higher-gloss finish, and they can be cured more quickly.

- The use of water-based varnishes is also becoming more popular because they are more environmentally friendly than solvent-based varnishes.

- The development of new roller varnishing machines is also making it possible to produce higher-quality finishes at faster speeds.

6. What are the different types of roller varnish applicators?

- Brush applicators: These applicators are used to apply varnish by hand. They are typically used for small projects or for touch-ups.

- Roller applicators: These applicators are used to apply varnish with a roller. They are typically used for larger projects or for applying a more even finish.

- Spray applicators: These applicators are used to apply varnish with a spray gun. They are typically used for large projects or for applying a very thin finish.

7. What are the different types of roller varnish finishes?

- Gloss finish: This finish is characterized by its high level of shine. It is typically used for projects that need to look shiny and new.

- Matte finish: This finish is characterized by its low level of shine. It is typically used for projects that need to look more natural or understated.

- Satin finish: This finish is characterized by its medium level of shine. It is typically used for projects that need to look both shiny and matte.

8. What are the different types of roller varnish substrates?

- Paper: Paper is a common substrate for roller varnishing. It is typically used for projects that need to be lightweight and inexpensive.

- Cardboard: Cardboard is a thicker and more durable substrate than paper. It is typically used for projects that need to be more durable or that need to be able to withstand more wear and tear.

- Wood: Wood is a strong and durable substrate. It is typically used for projects that need to be able to withstand heavy use or that need to be able to withstand the elements.

- Metal: Metal is a very durable substrate. It is typically used for projects that need to be able to withstand extreme temperatures or that need to be able to withstand corrosion.

9. What are the different types of roller varnish patterns?

- Solid pattern: This pattern is characterized by a solid color that is applied evenly over the entire substrate.

- Striped pattern: This pattern is characterized by a series of stripes that are applied over the substrate. The stripes can be of different colors or they can be of the same color.

- Checkered pattern: This pattern is characterized by a series of squares that are applied over the substrate. The squares can be of different colors or they can be of the same color.

10. What are the different types of roller varnish textures?

- Smooth texture: This texture is characterized by its smooth and even surface. It is typically used for projects that need to look sleek and professional.

- Rough texture: This texture is characterized by its rough and uneven surface. It is typically used for projects that need to look more natural or rustic.

- Textured texture: This texture is characterized by its textured surface. The texture can be created by using a variety of methods, such as sanding, brushing, or rolling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roller Varnisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roller Varnisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Roller Varnisher plays a crucial role in the printing industry by applying varnish or coating to printed materials. They operate specialized machinery to achieve precise and consistent results, ensuring the quality and protection of printed products.

1. Varnishing and Coating

Using advanced varnishing machines, Roller Varnishers apply varnish or coating to printed sheets, brochures, magazines, and other materials. They adjust settings and maintain proper viscosity and thickness to achieve desired effects.

- Operate roller coating machines to apply varnish or coating

- Calibrate equipment to ensure accurate varnish application

2. Color Matching and Control

Roller Varnishers ensure color consistency and accuracy by matching varnish shades to customer specifications. They use colorimeters and spectrophotometers to measure and adjust colors, ensuring optimal print quality.

- Match varnish color to customer requirements

- Use colorimeters to measure and adjust color accuracy

3. Quality Control and Inspection

Roller Varnishers are responsible for monitoring the quality of finished products. They inspect printed materials for defects, such as smudging, streaks, or improper drying. They ensure adherence to quality standards and customer specifications.

- Inspect finished products for quality and accuracy

- Identify and rectify any defects in the varnishing process

4. Machine Maintenance and Troubleshooting

Roller Varnishers maintain and troubleshoot roller coating machines to ensure optimal performance. They perform regular cleaning, lubrication, and adjustments to minimize downtime and ensure consistent production.

- Perform routine maintenance and cleaning of equipment

- Troubleshoot and resolve machine malfunctions

Interview Tips

To ace an interview for a Roller Varnisher position, it is crucial to showcase your technical skills, attention to detail, and passion for quality.

1. Highlight Technical Expertise

Emphasize your proficiency in operating roller coating machines, color matching techniques, and quality control procedures. Provide specific examples of how you have used your technical expertise to solve problems and achieve exceptional results.

- Discuss your experience in calibrating equipment for accurate varnish application

- Share how you have used colorimeters to measure and adjust color accuracy to customer specifications

2. Demonstrate Attention to Detail

Highlight your meticulous nature and attention to detail. Explain how you carefully inspect printed materials for any defects or inconsistencies. Emphasize your commitment to meeting or exceeding quality standards.

- Describe your process for identifying and rectifying any varnishing defects

- Mention your experience in maintaining a clean and organized work area

3. Convey Your Passion for Quality

Express your passion for delivering high-quality printed products. Explain how you take pride in your work and strive for excellence. Discuss your understanding of the importance of varnishing in protecting and enhancing the value of printed materials.

- Share examples of how you have gone the extra mile to ensure customer satisfaction

- Describe your commitment to continuous improvement and innovation in the varnishing process

4. Prepare for Common Interview Questions

Prepare for common interview questions such as “Tell me about your experience in roller varnishing,” “How do you handle defects in the varnishing process,” and “Why are you interested in this role?” Practice answering these questions concisely and professionally, showcasing your skills and qualifications.

- Research the company and industry to demonstrate your knowledge and interest

- Dress professionally and arrive on time for the interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roller Varnisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.