Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rolling Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

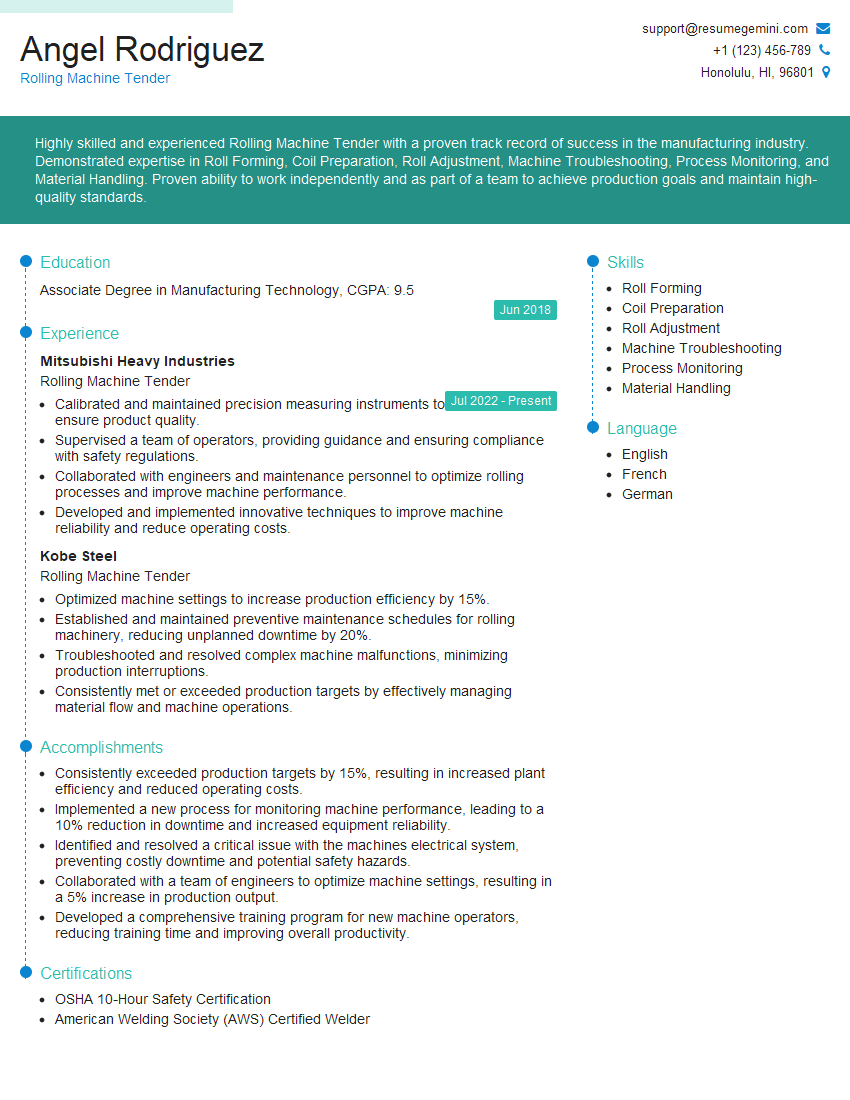

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rolling Machine Tender

1. Describe the key responsibilities of a Rolling Machine Tender.

- Operate and monitor rolling machines to produce sheet or strip metal.

- Ensure proper alignment and operation of the equipment.

- Inspect the finished product and make adjustments as needed.

- Maintain the work area and equipment.

2. What are the different types of rolling machines?

- Two-high rolling mills: Used for rolling flat products, such as sheets and plates.

- Four-high rolling mills: Used for rolling thicker products, such as bars and rods.

- Cluster mills: Used for rolling thin products, such as foil.

- Sendzimir mills: Used for rolling high-precision products, such as electronic components.

3. What are the key factors that affect the quality of rolled products?

- Material composition: The chemical composition of the metal can affect its strength, hardness, and other properties.

- Rolling temperature: The temperature at which the metal is rolled can affect its grain structure and mechanical properties.

- Rolling speed: The speed at which the metal is rolled can affect its thickness and surface finish.

- Roll gap: The distance between the rolls can affect the thickness and shape of the rolled product.

- Lubrication: The use of lubricants can reduce friction and improve the surface finish of the rolled product.

4. What are the safety precautions that must be taken when operating a rolling machine?

- Wear proper safety gear: This includes safety glasses, gloves, and earplugs.

- Be aware of the moving parts: Keep hands and feet away from the rolls and other moving parts.

- Never reach over the machine: Use a stick or other tool to adjust the rolls or other settings.

- Keep the work area clean: Grease and other debris can cause slips and falls.

- Be aware of the emergency stop button: Know where it is located and be prepared to use it in case of an emergency.

5. What are the maintenance procedures for a rolling machine?

- Daily: Clean the machine and lubricate all moving parts.

- Weekly: Inspect the rolls for wear and tear.

- Monthly: Replace the oil in the gearboxes and hydraulic systems.

- Annually: Perform a thorough inspection of the machine, including the electrical system and safety devices.

6. What is the difference between hot rolling and cold rolling?

- Hot rolling: Metal is rolled at a high temperature, which makes it more pliable and easier to shape.

- Cold rolling: Metal is rolled at a lower temperature, which makes it harder and stronger.

7. What are the different types of defects that can occur in rolled products?

- Edge cracks: These are cracks that occur at the edges of the rolled product.

- Center cracks: These are cracks that occur in the center of the rolled product.

- Laminations: These are layers of metal that are not bonded together properly.

- Inclusions: These are foreign objects that are embedded in the rolled product.

8. What are the causes of defects in rolled products?

- Improper rolling temperature: Rolling the metal at too high or too low a temperature can cause defects.

- Improper rolling speed: Rolling the metal at too high or too low a speed can cause defects.

- Improper roll gap: Setting the roll gap too wide or too narrow can cause defects.

- Improper lubrication: Using the wrong lubricant or not using enough lubricant can cause defects.

- Equipment malfunctions: Defects can also be caused by malfunctions in the rolling machine.

9. How can defects in rolled products be prevented?

- Use the correct rolling temperature, speed, and roll gap.

- Use the proper lubricant.

- Maintain the rolling machine properly.

- Inspect the rolled product regularly for defects.

10. What is the future of the rolling industry?

- Increased automation: Rolling machines are becoming increasingly automated, which is reducing the need for human operators.

- Improved materials: New materials are being developed that are stronger and more durable, which is making it possible to produce rolled products with better properties.

- New applications: Rolled products are being used in a wider variety of applications, such as in the automotive and aerospace industries.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rolling Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rolling Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rolling Machine Tender is responsible for operating and maintaining rolling machines, which are used to shape and form metal into various products. The key job responsibilities include:

1. Machine Operations

Operate rolling machines to shape and form metal products according to specified dimensions and tolerances.

- Set up and adjust machines to meet production requirements.

- Monitor machine performance and make necessary adjustments.

2. Material Handling

Handle and load metal coils or sheets onto rolling machines.

- Unload formed metal products from machines.

- Inspect materials for defects and compliance with specifications.

3. Quality Control

Monitor and control the quality of rolled products.

- Inspect finished products for dimensions, shape, and surface quality.

- Identify and correct any deviations from specifications.

4. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting on rolling machines.

- Lubricate and clean machines.

- Identify and resolve minor malfunctions.

- Report major equipment issues to maintenance personnel.

Interview Tips

To ace the interview for a Rolling Machine Tender position, it is essential to prepare thoroughly. Here are some tips:

1. Research the Company and Industry

Learn about the company’s products, services, and industry trends. This shows the interviewer that you are genuinely interested in the position and the company.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Network with people in the industry.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills and experience as a Rolling Machine Tender. Practice answering these questions concisely and confidently.

- Tell me about your experience operating rolling machines.

- How do you handle defects or non-conformance issues?

- What is your understanding of quality control in a rolling mill?

3. Showcase Technical Knowledge

Emphasize your technical knowledge and understanding of the rolling process. Show the interviewer that you are familiar with different types of rolling machines and materials used.

- Discuss the principles of metal forming and shaping.

- Explain the importance of machine calibration and maintenance.

- Share any experience you have with troubleshooting and resolving machine issues.

4. Highlight Safety and Compliance

Rolling Machine Tenders are responsible for ensuring a safe and compliant work environment. Emphasize your commitment to safety by highlighting your knowledge of industry regulations.

- Explain your understanding of HAZOP (Hazard and Operability Study).

- Describe safe operating procedures and emergency protocols.

- Share examples of how you have implemented safety improvements in previous roles.

5. Be Prepared to Answer Behavioral Questions

Interviewers often use behavioral questions to assess your soft skills and work ethic. Be prepared to answer questions about your teamwork, problem-solving abilities, and ability to work under pressure.

- Tell me about a time you had to resolve a problem on the job.

- How do you handle working in a fast-paced environment?

- Describe a time when you had to communicate technical information to a non-technical audience.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rolling Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!