Feeling lost in a sea of interview questions? Landed that dream interview for Rolling Mill Operator Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rolling Mill Operator Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

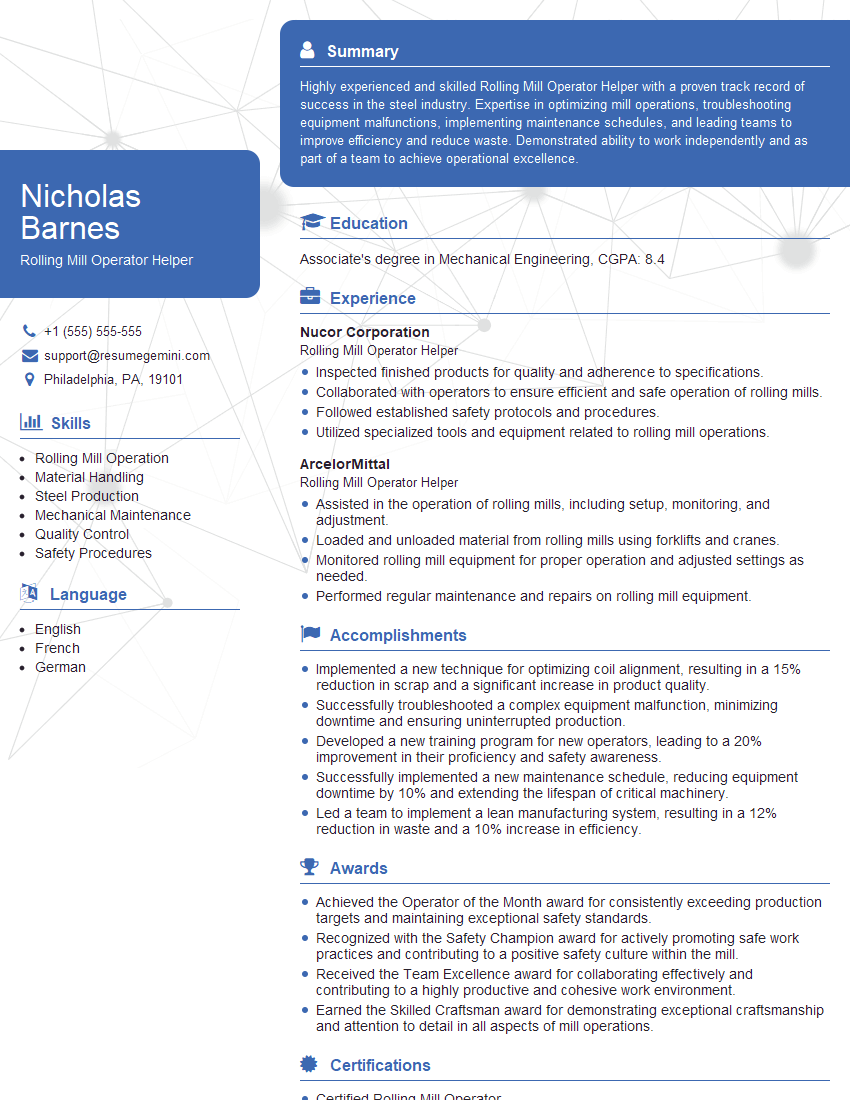

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rolling Mill Operator Helper

1. Describe the process of setting up a rolling mill for a specific order.

In order to set up a rolling mill for a specific order, I would first need to:

- Review the order specifications, including the desired product dimensions, material type, and quantity.

- Select the appropriate rolls and tooling for the job.

- Configure the mill settings, such as roll speed, pressure, and temperature.

- Load the material into the mill.

- Start the rolling process and monitor it closely.

2. Explain the different types of rolling mills and their applications.

There are several types of rolling mills, each with its own unique application:

Hot rolling mills

- Used to roll metal at high temperatures, making it more pliable and easier to shape.

- Typically used for producing structural shapes, such as beams, channels, and plates.

Cold rolling mills

- Used to roll metal at room temperature, resulting in a smoother, more precise finish.

- Often used for producing sheet metal, strip steel, and other precision components.

Tube mills

- Used to produce seamless and welded tubes.

- Can be either hot or cold rolling mills.

Reversing mills

- Used to roll thick, heavy plates.

- The rolls reverse direction with each pass, providing better control over the rolling process.

3. What are the key safety considerations when operating a rolling mill?

When operating a rolling mill, it is crucial to prioritize safety:

- Wear appropriate protective gear, including safety glasses, gloves, and earplugs.

- Be aware of the location of all pinch points and keep hands clear.

- Never operate the mill without proper training and authorization.

- Follow all established safety procedures and protocols.

- Report any unsafe conditions or equipment malfunctions immediately.

4. Describe the different types of defects that can occur in rolled products and how to prevent them.

Several types of defects can occur in rolled products:

- Surface defects: Scratches, dents, and other imperfections on the surface of the product. These can be caused by improper handling, storage, or rolling conditions.

- Dimensional defects: Variations in the product’s dimensions from the specified tolerances. These can be caused by incorrect mill settings or improper material preparation.

- Internal defects: Cracks, voids, and other imperfections within the product. These can be caused by material defects or improper rolling conditions.

To prevent these defects, it is important to:

- Use high-quality materials.

- Properly prepare the material before rolling.

- Configure the mill settings correctly.

- Monitor the rolling process closely.

- Inspect the finished products carefully.

5. What are the different maintenance tasks that need to be performed on a rolling mill?

Regular maintenance is essential to keep a rolling mill operating safely and efficiently:

- Daily maintenance: Lubricating moving parts, checking fluid levels, and inspecting for any loose or damaged components.

- Weekly maintenance: Cleaning the mill, checking the rolls for wear, and calibrating the sensors.

- Monthly maintenance: Replacing worn parts, such as bearings and seals, and performing more in-depth inspections.

- Annual maintenance: Overhauling the mill, including replacing major components and performing a thorough inspection of all systems.

6. How do you troubleshoot common problems that can occur with a rolling mill?

Troubleshooting common problems with a rolling mill requires a combination of knowledge and experience:

- Material is not feeding properly: Check the material loading mechanism and ensure the material is properly prepared.

- Rolls are slipping: Check the roll tension and adjust as necessary.

- Finished product is not meeting specifications: Inspect the rolls for wear or damage and adjust the mill settings.

- Mill is making excessive noise: Check the bearings and other rotating components for wear or damage.

- Mill is overheating: Check the cooling system and ensure it is functioning properly.

7. What are the different types of materials that can be rolled in a rolling mill?

Rolling mills can process a wide variety of materials, including:

- Steel

- Aluminum

- Copper

- Brass

- Nickel

- Titanium

8. What are the different factors that affect the quality of the rolled product?

The quality of the rolled product is influenced by several factors:

- Material quality: The type and condition of the material being rolled.

- Mill settings: The temperature, speed, and pressure at which the material is rolled.

- Roll condition: The condition of the rolls, including their surface finish and wear.

- Lubrication: The type and amount of lubrication used during the rolling process.

- Cooling: The method and rate at which the material is cooled after rolling.

9. What are the different applications of rolled products?

Rolled products have a wide range of applications, including:

- Automotive

- Construction

- Aerospace

- Consumer goods

- Industrial machinery

10. What are the career advancement opportunities for a Rolling Mill Operator Helper?

With experience and additional training, a Rolling Mill Operator Helper can advance to the following roles:

- Rolling Mill Operator

- Rolling Mill Supervisor

- Rolling Mill Maintenance Technician

- Rolling Mill Production Manager

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rolling Mill Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rolling Mill Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rolling Mill Operator Helpers play a crucial role in ensuring the smooth functioning of a rolling mill. Their responsibilities encompass various aspects of the operation, including:

1. Equipment Operation

Assist Rolling Mill Operators in the safe and efficient operation of rolling mills, including setting up and adjusting equipment.

- Loading and unloading materials, such as metal coils and sheets.

- Monitoring and adjusting the speed and tension of the rolling process.

2. Process Control

Help maintain the quality of rolled products by adhering to specified process parameters and monitoring gauges and controls.

- Inspecting rolled materials for defects and reporting any irregularities to the Rolling Mill Operator.

- Performing minor adjustments to the rolling process to ensure optimal product quality.

3. Maintenance and Cleaning

Assist in the maintenance and cleaning of rolling mills and related equipment to ensure optimal performance and prevent breakdowns.

- Lubricating mill components and performing routine maintenance tasks.

- Cleaning the mill and work area to maintain a safe and productive environment.

4. Safety and Environmental Compliance

Follow all safety protocols and regulations to minimize risks and ensure a safe work environment.

- Wearing appropriate personal protective equipment (PPE) and following safe work practices.

- Adhering to environmental regulations and ensuring the proper disposal of waste materials.

Interview Tips

To excel in a Rolling Mill Operator Helper interview, it’s essential to prepare effectively. Here are some valuable tips:

1. Research the Company and Industry

Thoroughly research the company you’re applying to, its mission, values, and industry standing. This will demonstrate your interest and understanding of the field.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience. Focus on questions related to your ability to work in a team, solve problems, and handle physical tasks.

3. Emphasize Your Technical Skills

Highlight your technical skills and knowledge of rolling mill operations. If you have experience with specific types of rolling mills or equipment, be sure to mention it.

4. Showcase Your Work Ethic and Attention to Detail

Emphasize your strong work ethic, ability to follow instructions precisely, and attention to detail. These qualities are crucial for ensuring the smooth and efficient operation of a rolling mill.

5. Prepare Industry-Specific Questions

Prepare industry-specific questions to ask the interviewer. This shows your interest in the field and eagerness to learn more about the company’s operations.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rolling Mill Operator Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rolling Mill Operator Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.