Feeling lost in a sea of interview questions? Landed that dream interview for Rolling Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rolling Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

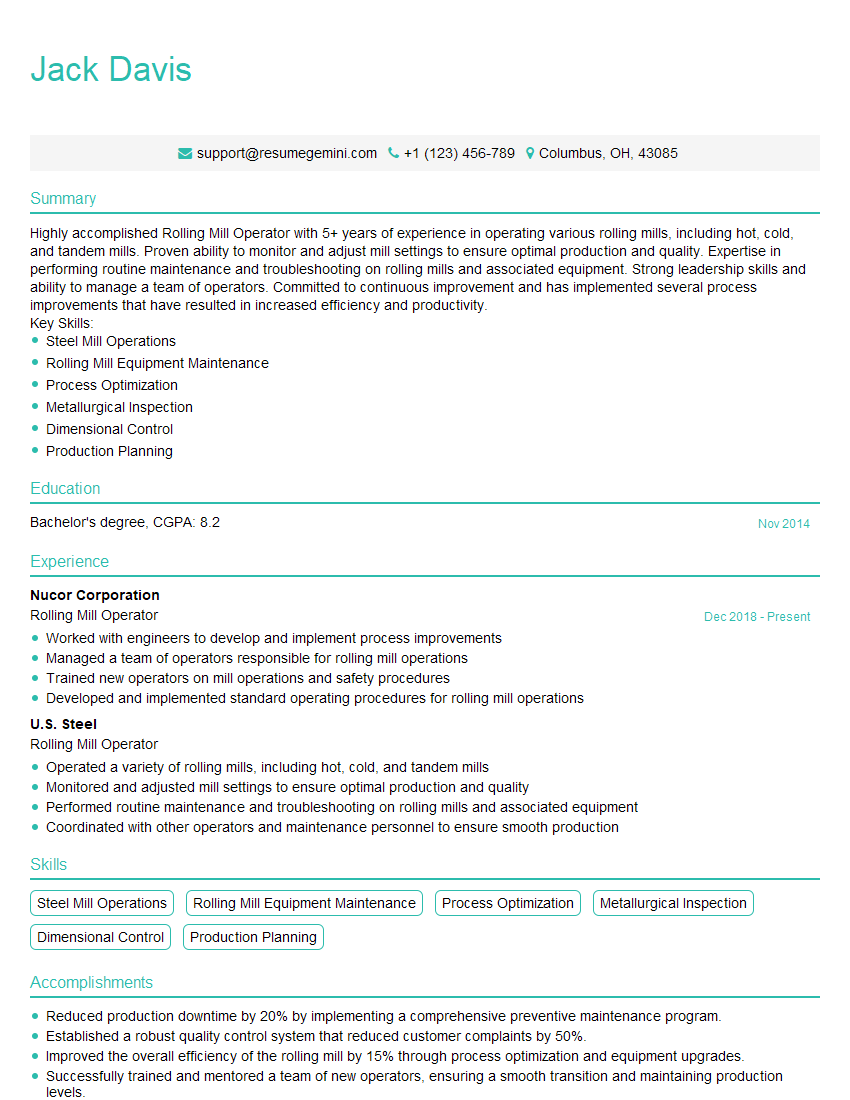

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rolling Mill Operator

1. Describe the process of setting up a rolling mill.

Setting up a rolling mill involves the following steps:

- Inspecting the mill and ensuring that it is in good working condition.

- Adjusting the mill settings to the desired specifications.

- Threading the material through the mill.

- Starting the mill and monitoring the process.

- Making adjustments to the mill settings as needed.

2. What are the different types of rolling mills?

Hot Rolling Mills

- Blooming Mill

- Slabbing Mill

- Plate Mill

- Hot Strip Mill

Cold Rolling Mills

- Reversing Cold Rolling Mill

- Continuous Cold Rolling Mill

- Temper Mill

- Skin Pass Mill

3. What are the safety precautions that must be taken when operating a rolling mill?

Safety precautions for operating a rolling mill include:

- Wearing appropriate safety gear, including hard hat, safety glasses, and gloves.

- Being aware of the location of emergency stop buttons.

- Keeping the work area clean and free of debris.

- Never reaching into the mill while it is running.

- Following all safety procedures and guidelines.

4. What are the common problems that can occur during rolling and how do you troubleshoot them?

Common problems that can occur during rolling and troubleshooting methods include:

- Chatter: Caused by improper mill setup or worn rolls. Adjust mill settings or replace rolls.

- Edge cracks: Caused by improper edge preparation or excessive roll wear. Adjust edge preparation or replace rolls.

- Center cracks: Caused by excessive reduction or improper mill setup. Reduce reduction or adjust mill settings.

- Roll marks: Caused by worn rolls or improper lubrication. Replace rolls or adjust lubrication.

- Scale: Caused by insufficient descaling or improper cooling. Increase descaling or adjust cooling process.

5. How do you maintain a rolling mill?

Rolling mill maintenance includes:

- Regularly inspecting and cleaning the mill.

- Lubricating the mill according to the manufacturer’s recommendations.

- Replacing worn parts as needed.

- Calibrating the mill to ensure accuracy.

- Following all maintenance procedures and guidelines.

6. What are the different types of materials that can be rolled?

- Steel

- Aluminum

- Copper

- Brass

- Titanium

7. What are the different shapes that can be rolled?

- Flat

- Round

- Square

- Rectangular

- Oval

8. What are the different thicknesses that can be rolled?

The thickness of material that can be rolled depends on the type of mill and the material being rolled. Generally, thicknesses can range from a few millimeters to several centimeters.

9. What are the different widths that can be rolled?

The width of material that can be rolled depends on the type of mill and the material being rolled. Generally, widths can range from a few centimeters to several meters.

10. What are the different surface finishes that can be achieved?

- Hot rolled

- Cold rolled

- Annealed

- Pickled

- Galvanized

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rolling Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rolling Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rolling Mill Operators are responsible for overseeing high-volume machines to transform metal billets into various shapes and sizes. Their key duties encompass:

1. Machine Operation and Monitoring

Operate and monitor rolling mill equipment to shape and size metal billets according to specifications.

- Adjust and maintain equipment settings to achieve desired product dimensions and quality.

- Monitor process parameters (e.g., temperature, pressure) to ensure optimal operation.

2. Quality Control and Inspection

Perform regular inspections of finished products to ensure compliance with quality standards.

- Identify and rectify any defects or variations from specifications.

- Maintain accurate records of inspections and quality control measures.

3. Machine Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting of rolling mill equipment.

- Identify and resolve minor operational issues to minimize downtime.

- Report any major issues or repairs to supervisors promptly.

4. Safety and Compliance

Uphold safety regulations and industry best practices in the workplace.

- Wear appropriate personal protective equipment (PPE) and follow safety protocols.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

To ace an interview for a Rolling Mill Operator position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This demonstrates your interest and enthusiasm.

- Visit the company’s website and LinkedIn page to gather information.

- Read industry publications and news articles to stay updated on the latest developments.

2. Highlight Your Technical Skills

Emphasize your technical expertise in operating and maintaining rolling mill equipment.

- Provide specific examples of your experience in setting up, calibrating, and troubleshooting machines.

- Explain how your knowledge of metallurgy and material properties helps you optimize the rolling process.

3. Showcase Your Quality-Oriented Mindset

Demonstrate your commitment to producing high-quality products and adhering to specifications.

- Share examples of how you implemented quality control measures to identify and address defects.

- Discuss your understanding of industry standards and regulations related to product quality.

4. Prepare for Safety-Related Questions

Expect questions about your safety practices and knowledge of industry regulations.

- Emphasize your adherence to safety protocols and your ability to identify and mitigate risks.

- Explain your understanding of emergency procedures and your role in maintaining a safe work environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rolling Mill Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rolling Mill Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.