Are you gearing up for a career in Rope Laying Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rope Laying Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

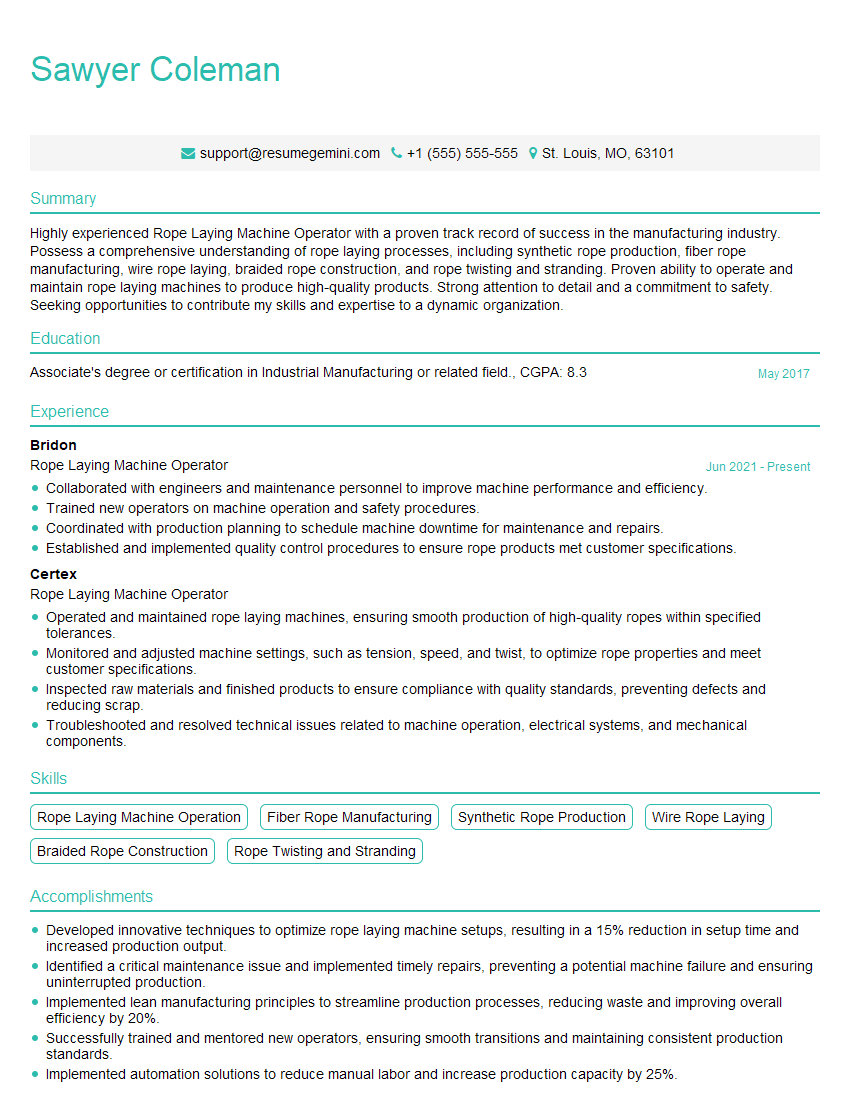

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rope Laying Machine Operator

1. What are the key components of a rope laying machine and explain their functions?

- Pay-off: It holds and guides the input strands from the creel.

- Capstan: It wraps the strands together to form a rope. The speed of the capstan determines the lay length of the rope.

- Binder: It applies adhesive or heat to bond the strands together.

- Creel: It holds the individual strands that are fed into the pay-off.

- Traverse: It moves the capstan and binder along the length of the rope to ensure even laying.

2. Describe the process of setting up a rope laying machine for a specific rope construction?

Pre-setup

- Determine the required rope construction, lay length, and diameter.

- Select the appropriate strands and materials.

Machine setup

- Install the strands in the creel and feed them through the pay-off.

- Set the capstan speed and tension based on the desired lay length.

- Adjust the binder settings for the appropriate adhesive or heat.

- Set the traverse speed and stroke length.

Calibration and testing

- Run a short test batch of rope to verify the settings.

- Measure and inspect the rope to ensure it meets specifications.

3. How do you troubleshoot common issues that occur during rope laying operations?

- Rope breakage: Check strand tension, binding quality, and machine alignment.

- Uneven lay: Adjust traverse speed or binder settings.

- Overheating: Check binder temperature and airflow.

- Mechanical malfunctions: Inspect and repair components such as bearings, gears, or motors.

4. What are the safety precautions that should be taken when operating a rope laying machine?

- Wear appropriate personal protective equipment (PPE).

- Inspect the machine and ensure it is in good working condition.

- Follow proper operating procedures.

- Be aware of pinch points and moving parts.

- Keep the work area clean and free of obstructions.

5. How do you calculate the production rate of a rope laying machine?

- Determine the desired rope length and diameter.

- Calculate the theoretical production rate based on the machine specifications and the number of strands.

- Adjust the production rate based on factors such as machine efficiency and material handling time.

6. What are the different types of ropes that can be produced using a rope laying machine?

- Stranded ropes: Made by twisting multiple strands together.

- Braided ropes: Made by interweaving strands in a braid pattern.

- Twisted ropes: Made by twisting a single strand into a rope.

- Synthetic ropes: Made from materials such as nylon, polyester, or polypropylene.

- Natural fiber ropes: Made from materials such as cotton, jute, or sisal.

7. How do you maintain a rope laying machine to ensure optimal performance?

- Regular cleaning and lubrication.

- Inspection and replacement of worn or damaged parts.

- Calibration and adjustment of sensors and controls.

- Monitoring and troubleshooting of potential problems.

8. What are the various types of materials used in the production of ropes?

- Natural fibers: Cotton, jute, sisal, hemp

- Synthetic fibers: Nylon, polyester, polypropylene

- Metal fibers: Steel, stainless steel, aluminum

- Specialty fibers: Kevlar, Dyneema

9. How do you determine the appropriate type of rope for a specific application?

- Consider the required strength, flexibility, and durability.

- Determine the environmental conditions (e.g., moisture, temperature, chemicals).

- Evaluate the intended use (e.g., marine, construction, towing).

10. What are the latest advancements in rope laying technology?

- Computer-controlled machines: Improved accuracy and efficiency.

- Advanced materials: Ropes with enhanced properties (e.g., strength, durability).

- Automated quality control: Real-time monitoring and inspection.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rope Laying Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rope Laying Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rope Laying Machine Operators are responsible for the operation and maintenance of rope laying equipment used to manufacture ropes for various industries, such as construction, marine, and manufacturing.

1. Machine Operation

- Operate and monitor rope laying machines to produce ropes of different sizes, types, and specifications.

- Control machine settings, such as tension, speed, and temperature, to ensure optimal rope production.

- Monitor machine performance and make adjustments to maintain efficient operation.

2. Material Handling

- Load and unload raw materials (e.g., fibers, yarns) into and out of the machines.

- Inspect materials for defects and verify their compliance with specifications.

- Maintain proper inventory levels of materials and ensure the efficient flow of materials throughout the production process.

3. Quality Control

- Inspect produced ropes for defects and ensure they meet quality standards.

- Identify and correct any quality issues by adjusting machine settings or performing minor repairs.

- Maintain records of quality checks and inspections for documentation and compliance purposes.

4. Machine Maintenance

- Perform routine maintenance tasks, such as cleaning, lubrication, and minor repairs.

- Monitor machine performance and identify potential maintenance issues.

- Coordinate with maintenance technicians for major repairs or upgrades.

5. Safety Compliance

- Follow established safety procedures and wear appropriate safety gear.

- Operate machines in a safe and responsible manner, minimizing risks to themselves and others.

- Report any safety concerns or incidents to supervisors immediately.

Interview Tips

To ace the interview as a Rope Laying Machine Operator, it is important to prepare thoroughly and showcase your relevant skills, experience, and knowledge:

1. Research the Company and Industry

- Visit the company’s website and familiarize yourself with their products, services, and industry standing.

- Research the specific industry to understand the latest trends and advancements in rope manufacturing.

2. Highlight Relevant Skills and Experience

- Emphasize your hands-on experience in operating and maintaining rope laying machines.

- Describe your knowledge of different types of ropes, materials, and their applications.

3. Prepare for Common Interview Questions

- Practice answering common interview questions, such as “Tell me about yourself” or “Why are you interested in this role?”

- Come prepared with specific examples of your accomplishments and skills that align with the job requirements.

4. Show Enthusiasm and Motivation

- Express your passion for the field and your desire to contribute to the company’s success.

- Be enthusiastic about learning new technologies and staying up-to-date with industry practices.

5. Be Punctual and Dress Professionally

- Arrive on time for your interview and dress appropriately, showing respect for the interviewer and the company.

- Maintaining a professional and courteous demeanor throughout the interview process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rope Laying Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!