Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rope Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

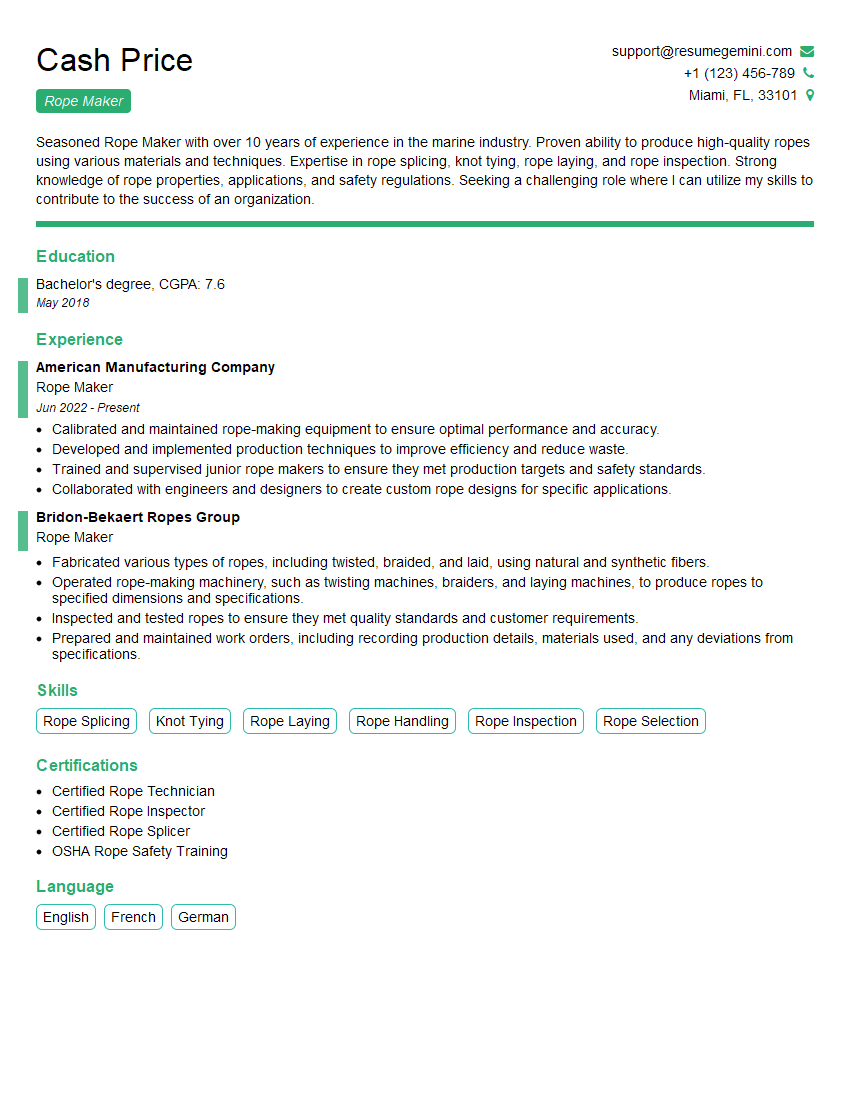

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rope Maker

1. Explain the different types of ropes available and their specific uses.

Different types of ropes are available, each with specific uses based on their material, construction, and properties. Some common types include:

- Natural fiber ropes: Made from materials like cotton, jute, hemp, or sisal, they are biodegradable and eco-friendly, but less durable and resistant to moisture.

- Synthetic fiber ropes: Made from materials like nylon, polyester, or polyethylene, they are strong, durable, and resistant to moisture, chemicals, and abrasion.

- Wire ropes: Constructed from metal wires twisted or braided together, they offer high strength, durability, and resistance to heat and wear.

- Combination ropes: Combine different materials to create ropes with specific properties, such as strength, flexibility, and resistance to specific conditions.

2. Describe the process of manufacturing ropes and the key factors that affect rope quality.

Rope manufacturing typically involves several steps:

Raw material preparation:

- Selecting and preparing fibers or wires to meet specific requirements.

Spinning:

- Twisting fibers or wires together to form yarns.

Stranding:

- Twisting yarns together to form strands.

Laying:

- Twisting strands together to form the final rope.

Key factors affecting rope quality include:

- Raw material quality

- Yarn and strand construction

- Laying techniques

- Quality control and testing

3. Explain the different tests performed to ensure rope quality and safety.

Various tests are conducted to ensure rope quality and safety, including:

- Tensile strength test: Measures the force required to break the rope.

- Breaking load test: Determines the maximum weight the rope can withstand before breaking.

- Bend test: Assesses the rope’s flexibility and resistance to bending.

- Abrasion resistance test: Measures the rope’s ability to withstand wear and tear.

- Chemical resistance test: Evaluates the rope’s resistance to chemicals and solvents.

- UV resistance test: Determines the rope’s ability to withstand exposure to ultraviolet rays.

4. Describe the principles of rope handling and storage to ensure safety and longevity.

Proper rope handling and storage are crucial for safety and longevity. Principles include:

- Inspecting ropes before use: Check for any damage or wear.

- Using proper handling techniques: Avoid kinking, twisting, or overloading ropes.

- Storing ropes properly: Keep ropes clean, dry, and away from direct sunlight and heat.

- Following manufacturer’s instructions: Refer to specific guidelines for handling and storage.

5. Explain the different methods used to splice ropes and the applications of each method.

Splicing involves joining two ropes without using knots. Common methods include:

- Three-strand splice: Used for joining ropes of the same diameter and material, providing a strong and flexible connection.

- Eye splice: Creates a loop at the end of a rope, used for attaching to hooks or rings.

- Short splice: Joins two ropes of different diameters, creating a permanent and strong connection.

6. Discuss the importance of rope maintenance and the signs that indicate the need for replacement.

Regular rope maintenance is essential for safety and performance. Signs indicating replacement include:

- Visible damage: Cuts, abrasions, or fraying.

- Reduced strength: Loss of tensile strength or breaking load.

- Stiffness: Reduced flexibility or bending ability.

- Corrosion: Rust or oxidation on wire ropes.

7. Explain the different types of rope accessories and their uses.

Various rope accessories enhance rope functionality and safety, including:

- Rope clamps: Secure ropes without tying knots, allowing for easy adjustment.

- Thimbles: Protect ropes from wear and tear at connection points.

- Hooks: Attach ropes to structures or objects.

- Pulley blocks: Change the direction of rope pull and reduce friction.

8. Describe the industry standards and regulations for rope usage and safety.

Rope usage and safety are guided by industry standards and regulations, such as:

- ANSI/ASME B30.9: Safety standard for slings.

- OSHA 1926.251: Regulations for rigging and hoisting equipment.

- Manufacturers’ guidelines: Specific instructions for rope handling, storage, and inspection.

9. Discuss the emerging trends and advancements in rope technology.

Rope technology is constantly evolving, with trends including:

- High-performance fibers: Development of stronger, lighter, and more durable materials.

- Nanotechnology: Incorporating nanoparticles to enhance rope properties.

- Smart ropes: Integration of sensors and monitoring systems to provide real-time data on rope condition.

10. How do you stay updated with the latest advancements and best practices in rope manufacturing and usage?

To stay updated, I regularly engage in the following practices:

- Attending industry conferences and exhibitions: Networking with experts and learning about new technologies.

- Reading technical journals and publications: Staying informed about research and advancements in the field.

- Participating in online forums and discussion groups: Exchanging knowledge and insights with industry professionals.

- Seeking training and certifications: Enhancing my skills and expanding my knowledge base.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rope Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rope Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rope makers are responsible for creating ropes and cords for a variety of uses. They work with a variety of fibers to create ropes of different sizes, strengths, and durability. Rope makers use a variety of tools and techniques to create their products, and they must have a strong understanding of the properties of different fibers and how they can be combined to create the desired result.

1. Create ropes and cords using a variety of fibers

Rope makers use a variety of fibers to create ropes and cords, including natural fibers such as cotton, hemp, and jute, and synthetic fibers such as nylon, polyester, and polypropylene.

- Select the appropriate fiber for the intended use of the rope or cord.

- Determine the correct diameter and length of the rope or cord.

- Twist or braid the fibers together to create the rope or cord.

2. Inspect ropes and cords for defects

Rope makers must inspect ropes and cords for defects before they are sold or used. They look for any signs of damage, such as cuts, tears, or fraying.

- Inspect the rope or cord for any visible defects.

- Test the strength of the rope or cord by pulling on it.

- Ensure that the rope or cord meets the required specifications.

3. Maintain and repair ropes and cords

Rope makers must maintain and repair ropes and cords to ensure that they are safe to use. They may need to replace damaged sections of rope or cord, or they may need to re-twist or re-braid the rope or cord to restore its strength.

- Identify any damaged sections of rope or cord.

- Replace the damaged section with a new piece of rope or cord.

- Re-twist or re-braid the rope or cord to restore its strength.

4. Provide technical assistance to customers

Rope makers may also provide technical assistance to customers who are using their products. They can help customers to choose the right rope or cord for their needs, and they can provide instructions on how to use and maintain the rope or cord.

- Answer customer questions about ropes and cords.

- Provide instructions on how to use and maintain ropes and cords.

- Help customers to choose the right rope or cord for their needs.

Interview Tips

To help you prepare for your interview for a rope maker position, consider these tips:

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you to understand the company’s culture and values, and it will also help you to tailor your answers to the interviewer’s questions.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise way.

3. Be prepared to talk about your experience

If you have any experience in rope making or in a related field, be sure to highlight it in your interview. This will show the interviewer that you have the skills and the knowledge to be successful in the position.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the position. Show the interviewer that you are excited about the opportunity to work for the company and that you are confident in your abilities.

5. Ask questions

At the end of the interview, be sure to ask the interviewer any questions that you have about the position or the company. This will show the interviewer that you are interested in the opportunity and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rope Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.