Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roper Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

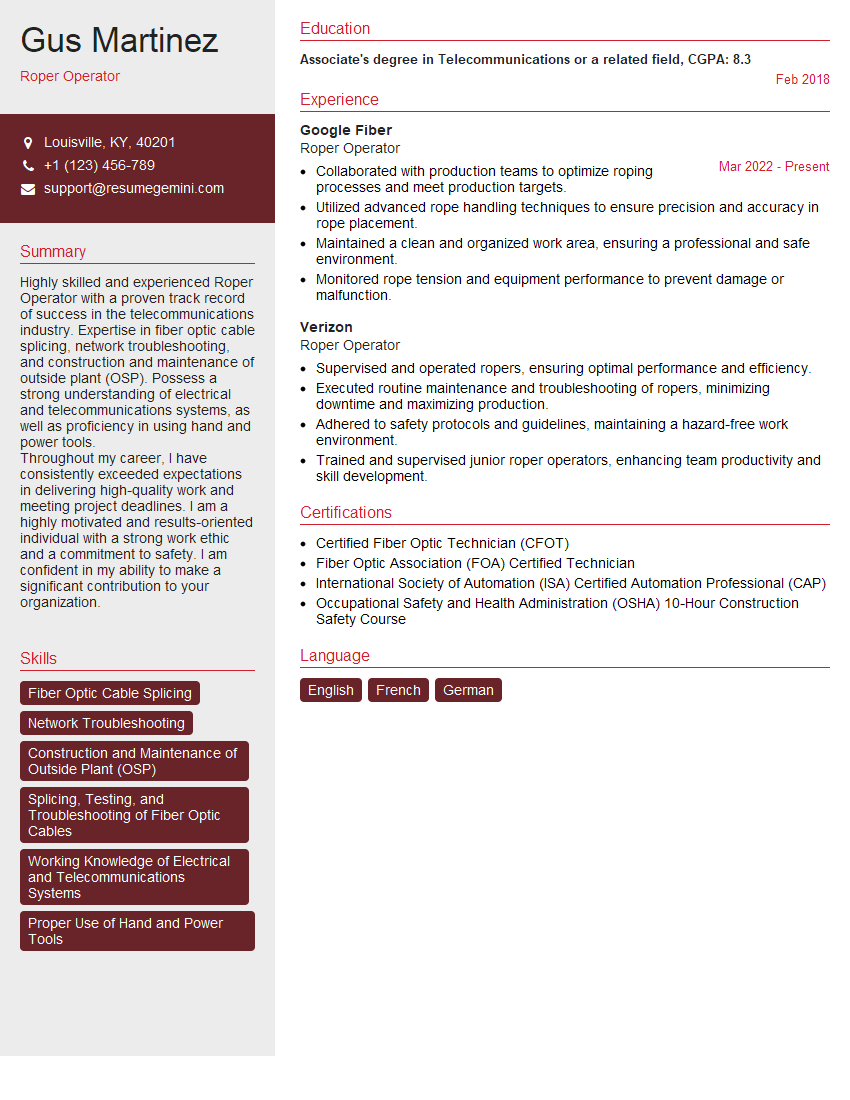

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roper Operator

1. What is the purpose of a roper?

- A roper is a machine used to form ropes by twisting together multiple strands of fiber.

- Ropers are used in various industries, including construction, manufacturing, and agriculture.

2. What are the different types of ropers?

- Single-twist ropers: These ropers produce ropes with a single twist, which makes them strong and durable.

- Double-twist ropers: These ropers produce ropes with a double twist, which makes them more flexible and resistant to kinking.

- Three-twist ropers: These ropers produce ropes with a triple twist, which makes them the strongest and most durable type of rope.

3. What are the factors that affect the quality of a rope?

- Fiber type: The type of fiber used in the rope will affect its strength, durability, and flexibility.

- Number of strands: The number of strands in the rope will affect its diameter and strength.

- Twist: The amount of twist in the rope will affect its strength, flexibility, and resistance to kinking.

- Coating: The rope may be coated with a material such as wax or tar to improve its resistance to water and abrasion.

4. What are the safety precautions that must be taken when operating a roper?

- Always wear safety glasses and gloves when operating a roper.

- Never operate a roper with loose clothing or jewelry that could get caught in the machine.

- Keep the work area clean and free of debris.

- Never reach into the roper while it is running.

- If the roper becomes jammed, turn it off and unplug it before attempting to clear the jam.

5. What are the maintenance procedures that must be performed on a roper?

- Regularly clean the roper to remove any debris or buildup.

- Oil the roper according to the manufacturer’s instructions.

- Inspect the roper for any damage or wear and tear.

- Have the roper serviced by a qualified technician on a regular basis.

6. What are the troubleshooting tips for a roper that is not working properly?

- Check the power supply to the roper.

- Inspect the roper for any damage or wear and tear.

- Clean the roper to remove any debris or buildup.

- Oil the roper according to the manufacturer’s instructions.

- If the problem persists, contact a qualified technician.

7. What are the different types of ropes that can be made with a roper?

- Natural fiber ropes: These ropes are made from natural fibers such as cotton, hemp, or jute.

- Synthetic fiber ropes: These ropes are made from synthetic fibers such as nylon, polyester, or polyethylene.

- Mixed fiber ropes: These ropes are made from a combination of natural and synthetic fibers.

8. What are the different applications for ropes?

- Construction: Ropes are used for a variety of construction applications, such as tying down scaffolding, hoisting materials, and securing equipment.

- Manufacturing: Ropes are used in manufacturing for a variety of purposes, such as conveying materials, tying down products, and bundling wires.

- Agriculture: Ropes are used in agriculture for a variety of purposes, such as tying down livestock, fencing fields, and pulling heavy equipment.

- Marine: Ropes are used in marine applications for a variety of purposes, such as securing boats, tying down sails, and towing equipment.

- Recreation: Ropes are used for a variety of recreational activities, such as climbing, camping, and boating.

9. What are the advantages of using a roper to make ropes?

- Increased production speed: Ropers can produce ropes much faster than manual methods.

- Improved rope quality: Ropers can produce ropes with a more consistent diameter and twist than manual methods.

- Reduced labor costs: Ropers can reduce the need for manual labor, which can save on labor costs.

- Increased safety: Ropers can reduce the risk of accidents by eliminating the need for manual labor.

10. What are the challenges of operating a roper?

- Proper setup: Ropers must be properly set up in order to produce high-quality ropes.

- Maintenance: Ropers require regular maintenance in order to operate properly.

- Troubleshooting: Ropers can sometimes experience problems, which can require troubleshooting to resolve.

- Safety: Ropers can be dangerous if they are not operated properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roper Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roper Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roper Operators are responsible for handling and operating ropers in a variety of industrial and construction settings. Their primary objective is to ensure the efficient and safe operation of these machines.

1. Machine Operation

Operate ropers to pull or move materials, such as dirt, rocks, or debris.

- Follow established operating procedures and safety guidelines.

- Monitor machine performance, troubleshoot any issues, and perform routine maintenance and adjustments.

2. Site Preparation

Prepare work sites by clearing obstacles, leveling ground, and setting up barricades as needed.

- Ensure that the work area is safe and compliant with regulations.

- Coordinate with other crew members to ensure efficient site preparation.

3. Material Handling

Load, unload, and transport materials using the roper.

- Inspect materials for quality and ensure they are handled properly.

- Maintain an organized and efficient material flow.

4. Equipment Maintenance

Inspect and maintain ropers regularly to ensure optimal performance and prevent breakdowns.

- Perform routine maintenance tasks such as cleaning, lubrication, and minor repairs.

- Report any major issues to supervisors for prompt resolution.

Interview Tips

To prepare for a Roper Operator interview and showcase your skills effectively, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s background, values, and the specific industry it operates in. This knowledge will help you understand the company’s needs and tailor your answers accordingly.

- Visit the company’s website to learn about their history, mission, and current projects.

2. Practice Common Interview Questions

Anticipate common interview questions related to your skills, experience, and motivation. Practice answering these questions concisely and confidently.

- Consider preparing for questions such as “Tell me about your experience operating ropers” or “Why are you interested in this position?”.

3. Highlight Relevant Experience

Emphasize your hands-on experience operating ropers and any relevant certifications or licenses you hold. Quantify your accomplishments and provide specific examples of your contributions.

- For instance, you could mention “In my previous role, I operated a roper to move over 100 tons of materials per day, resulting in a 15% increase in productivity.”

4. Demonstrate Safety Awareness

Stress your commitment to safety and adherence to industry regulations. Highlight your knowledge of safety protocols and practices related to roper operation.

- Provide examples of your safety measures, such as “I always conduct thorough pre-operation inspections and wear appropriate personal protective equipment.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roper Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.