Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ropewalk Rope Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ropewalk Rope Maker so you can tailor your answers to impress potential employers.

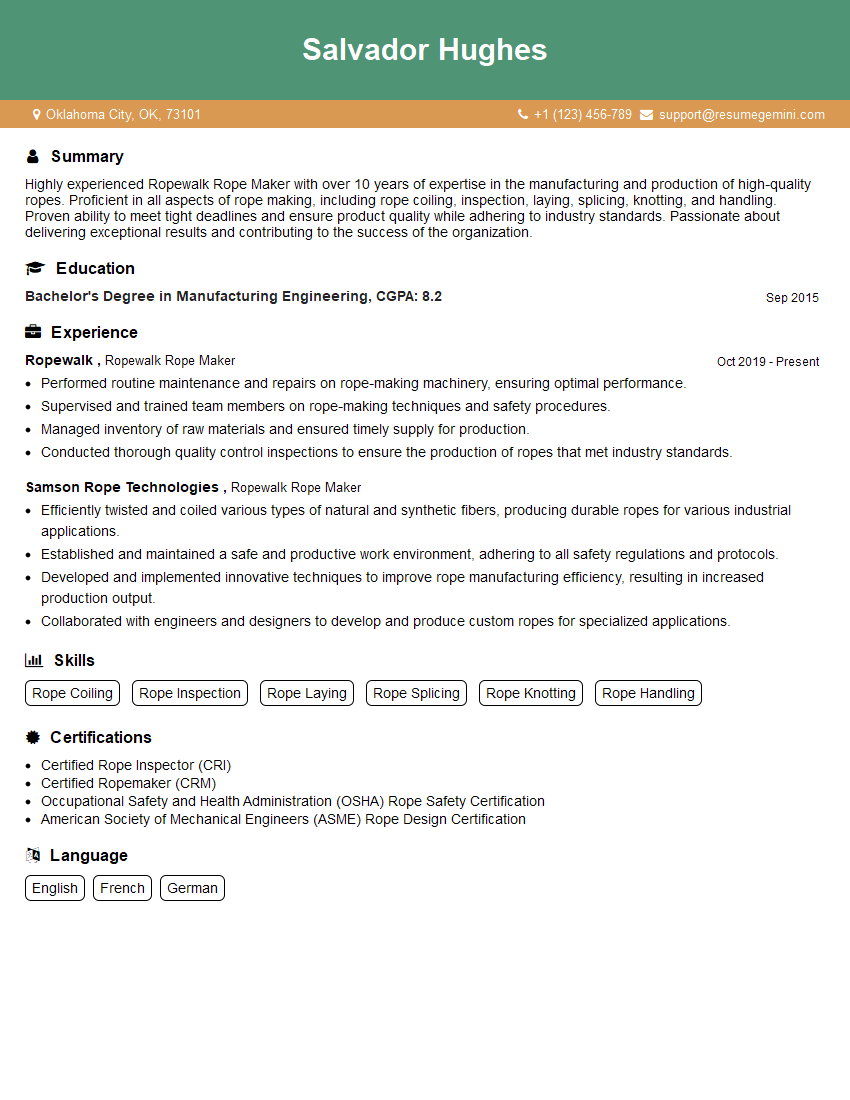

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ropewalk Rope Maker

1. Explain the process of making a three-strand twisted rope?

The process of making a three-strand twisted rope involves the following steps:

- Selecting the fibers: The first step is to select the fibers that will be used to make the rope. The most common fibers used for rope making are natural fibers such as cotton, hemp, and jute, or synthetic fibers such as nylon, polyester, and polypropylene.

- Preparing the fibers: The fibers are then prepared for spinning by removing any impurities and combing them to align the fibers.

- Spinning the fibers: The fibers are then spun into individual yarns. This can be done by hand or using a spinning machine.

- Twisting the yarns: The yarns are then twisted together to form strands. This can be done by hand or using a twisting machine.

- Laying the strands: The strands are then laid together in a specific pattern to form the rope. This can be done by hand or using a laying machine.

- Finishing the rope: The rope is then finished by applying a protective coating or treatment.

2. What are the different types of rope constructions?

Braided rope

- Braided rope is a type of rope that is made by braiding together three or more strands. Braided rope is very strong and durable, and it is often used for marine applications.

Twisted rope

- Twisted rope is a type of rope that is made by twisting together two or more strands. Twisted rope is less strong and durable than braided rope, but it is more flexible and easier to handle.

Plaited rope

- Plaited rope is a type of rope that is made by plaiting together three or more strands. Plaited rope is very strong and durable, and it is often used for decorative purposes.

Coiled rope

- Coiled rope is a type of rope that is made by coiling together a single strand. Coiled rope is very strong and durable, and it is often used for mooring boats and other heavy objects.

3. What are the factors that affect the strength of a rope?

The strength of a rope is affected by the following factors:

- The type of fiber used: The strength of a rope is determined by the strength of the fibers used to make it. Natural fibers are generally weaker than synthetic fibers.

- The construction of the rope: The construction of a rope also affects its strength. Braided rope is stronger than twisted rope, and plaited rope is stronger than coiled rope.

- The size of the rope: The size of a rope also affects its strength. A larger rope is stronger than a smaller rope.

- The condition of the rope: The condition of a rope also affects its strength. A rope that is damaged or worn is weaker than a rope that is in good condition.

4. What are the different uses of rope?

Rope is used for a variety of purposes, including:

- Mooring boats and other heavy objects

- Lifting and lowering heavy objects

- Tying down equipment and cargo

- Making nets and other fishing gear

- Making clothing and other accessories

5. What are the safety precautions that should be taken when using rope?

The following safety precautions should be taken when using rope:

- Never use a rope that is damaged or worn.

- Always inspect a rope before using it to make sure that it is in good condition.

- Never overload a rope.

- Always tie a knot that is appropriate for the application.

- Never leave a rope unattended.

6. What are the different types of knots that can be tied with rope?

There are many different types of knots that can be tied with rope. Some of the most common knots include:

- Square knot

- Bowline knot

- Clove hitch

- Sheet bend

- Figure-eight knot

7. How do you splice two ropes together?

To splice two ropes together, follow these steps:

- Unlay the strands of both ropes for a few inches.

- Interlock the strands of the two ropes, alternating between the ropes.

- Tuck the end of each strand under the next strand in the opposite rope.

- Continue tucking the strands until the splice is complete.

- Trim the excess strands.

8. What are the different types of rope materials?

There are many different types of rope materials, each with its own advantages and disadvantages. Some of the most common rope materials include:

- Natural fibers: Natural fibers are made from plants or animals. They are biodegradable and environmentally friendly, but they are not as strong or durable as synthetic fibers.

- Synthetic fibers: Synthetic fibers are made from man-made materials. They are stronger and more durable than natural fibers, but they are not biodegradable.

9. What are the different types of rope finishes?

There are many different types of rope finishes, each with its own advantages and disadvantages. Some of the most common rope finishes include:

- Plain finish: A plain finish is the most basic type of rope finish. It is simply the natural color of the rope fibers.

- Tarred finish: A tarred finish is a coating of tar that is applied to the rope. This makes the rope more resistant to water and abrasion.

- Waxed finish: A waxed finish is a coating of wax that is applied to the rope. This makes the rope more flexible and easier to handle.

10. What are the different types of rope accessories?

There are many different types of rope accessories, each with its own purpose. Some of the most common rope accessories include:

- Thimbles: Thimbles are metal sleeves that are placed over the ends of ropes to prevent them from fraying.

- Shackles: Shackles are U-shaped metal connectors that are used to join two ropes together.

- Blocks: Blocks are pulleys that are used to change the direction of a rope.

- Cleats: Cleats are devices that are used to secure ropes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ropewalk Rope Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ropewalk Rope Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ropewalk Rope Makers are highly skilled craftsmen responsible for producing ropes and cords used in various industries, including maritime, construction, and manufacturing. Their key responsibilities encompass:

1. Rope Production

The primary duty involves operating specialized machinery, such as ropewalks or rope-making machines, to twist and braid natural or synthetic fibers into ropes of varying sizes and specifications.

- Selecting and preparing raw materials (e.g., sisal, nylon, polyester)

- Calibrating and maintaining rope-making machinery

- Monitoring production processes to ensure quality and consistency

2. Quality Control

Ropewalk Rope Makers are responsible for maintaining the highest standards of quality in their products.

- Conducting regular inspections and testing to verify rope strength, durability, and adherence to specifications

- Identifying and rectifying any defects or errors in the production process

- Maintaining detailed records of production and quality assurance procedures

3. Equipment Maintenance

To ensure optimal production, Ropewalk Rope Makers are tasked with maintaining and repairing machinery and tools.

- Performing preventive maintenance tasks (e.g., lubrication, cleaning, adjustments)

- Troubleshooting and resolving equipment malfunctions

- Coordinating with maintenance personnel for major repairs or upgrades

4. Safety Compliance

The safety of themselves and their colleagues is paramount for Ropewalk Rope Makers.

- Adhering to all safety regulations and protocols

- Wearing appropriate protective gear (e.g., gloves, safety glasses, earplugs)

- Reporting any safety hazards or concerns to supervisors

Interview Tips

To help candidates ace their interview for a Ropewalk Rope Maker position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the rope-making industry. Learn about their products, processes, and market position.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Connect with industry professionals on LinkedIn

2. Practice Your Craft

Highlight your skills in rope production and quality control. If possible, bring samples of your work to the interview or be prepared to describe specific projects you’ve handled.

- Emphasize your understanding of different rope types, materials, and construction techniques

- Share examples of how you have maintained high quality standards in your previous roles

- Discuss your experience in using and maintaining rope-making machinery

3. Showcase Your Safety Mindset

Safety is crucial in this role. Emphasize your commitment to following safety protocols and maintaining a safe work environment.

- Highlight your knowledge of relevant safety regulations and best practices

- Describe how you have implemented safety measures in previous positions

- Demonstrate your ability to identify and mitigate potential hazards

4. Prepare for Technical Questions

Expect questions related to rope production techniques, equipment calibration, and quality assurance procedures. Review these topics thoroughly and be prepared to provide specific examples of your expertise.

- Study different types of ropes and their applications

- Practice answering questions about rope strength, durability, and testing methods

- Be familiar with common equipment used in rope-making and their maintenance procedures

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ropewalk Rope Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.