Are you gearing up for a career in Ross Furnace Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ross Furnace Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

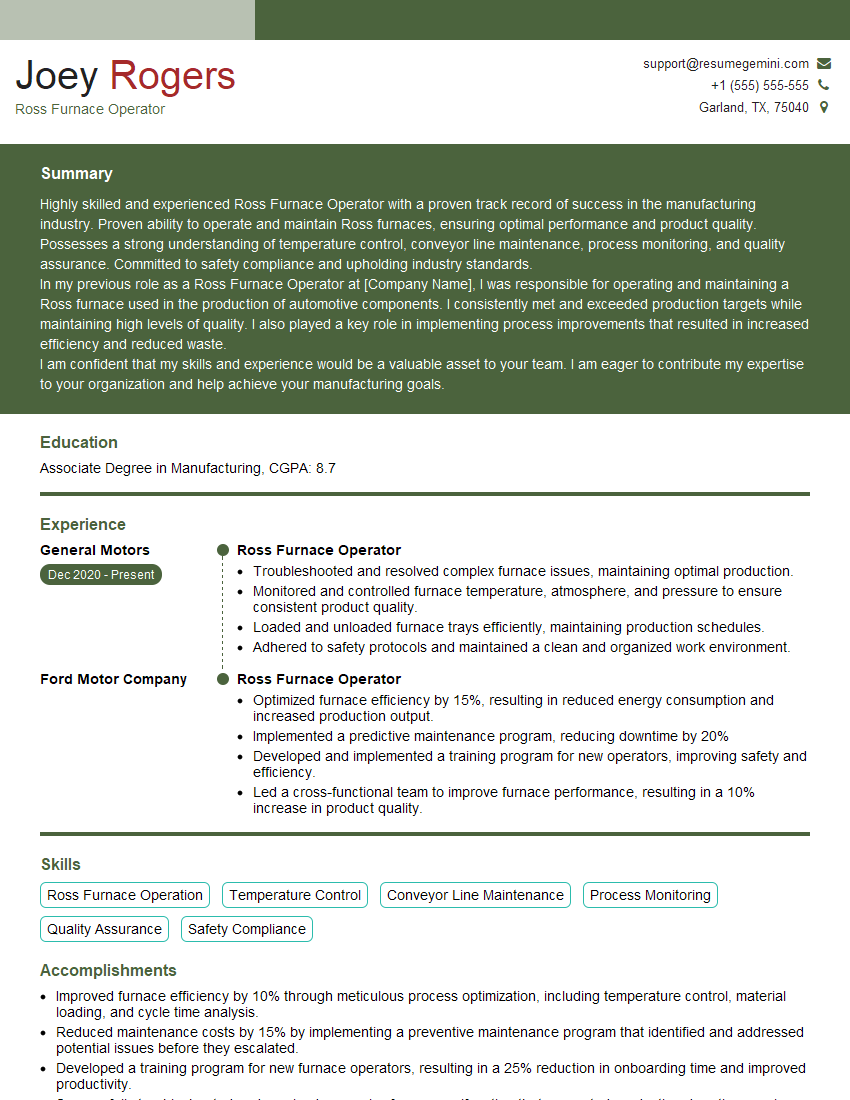

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ross Furnace Operator

1. Describe the typical duties and responsibilities of a Ross Furnace Operator?

As a Ross Furnace Operator, I am responsible for:

- Operating and monitoring the Ross Furnace, ensuring that it is operating efficiently and within specified parameters.

- Charging the furnace with scrap metal and flux materials, and maintaining the proper levels of these materials in the furnace.

- Controlling the temperature of the furnace and regulating the flow of oxygen and fuel to achieve the desired melt conditions.

- Skimming the slag and dross from the molten metal, and monitoring the metal composition to ensure that it meets quality standards.

- Troubleshooting and resolving any operational issues that may arise with the furnace or its associated equipment.

2. Explain the process of charging a Ross Furnace?

- Firstly, I ensure that the furnace is clean and ready for charging.

- I then use a loader to charge the furnace with scrap metal and flux materials.

- The scrap metal is loaded into the furnace in a specific sequence and at a controlled rate, to ensure proper melting and slag formation.

- The flux materials are added to remove impurities from the molten metal and promote slag formation.

3. How do you monitor and control the temperature of a Ross Furnace?

- The temperature of the furnace is monitored using thermocouples installed at various locations within the furnace.

- I use a control panel to regulate the flow of oxygen and fuel to the furnace, which directly affects the temperature.

- Regular temperature checks are performed to ensure that the furnace is operating within the desired temperature range.

4. Describe the importance of skimming the slag and dross from the molten metal?

- Skimming the slag and dross from the molten metal is essential to ensure the quality of the finished metal product.

- Slag is a non-metallic waste product that forms on the surface of the molten metal, and dross is a metallic oxide that forms on the surface or within the molten metal.

- If these impurities are not removed, they can degrade the quality of the metal and cause defects in the final product.

5. Explain how you troubleshoot and resolve operational issues with a Ross Furnace?

- When an operational issue arises, I first identify the symptoms and potential causes of the issue.

- I then use my technical knowledge and experience to develop a plan to resolve the issue.

- This may involve making adjustments to the furnace settings, replacing faulty components, or performing maintenance procedures.

- Once the issue is resolved, I monitor the furnace to ensure that it is operating correctly and efficiently.

6. Describe the safety precautions that must be taken when operating a Ross Furnace?

- It is crucial to wear appropriate personal protective equipment (PPE) such as heat-resistant clothing, gloves, and safety glasses.

- The furnace area must be well-ventilated to prevent the accumulation of harmful fumes.

- Regular inspections and maintenance of the furnace and its associated equipment are essential to ensure safe operation.

- Emergency procedures must be in place and communicated to all personnel working in the area.

7. Explain how you ensure the quality of the molten metal produced by the Ross Furnace?

- I monitor the composition of the molten metal regularly using a spectrometer or other analytical techniques.

- If the composition does not meet the desired specifications, I adjust the furnace settings or add corrective materials to bring it within the acceptable range.

- I maintain accurate records of the furnace operation and the quality of the molten metal produced.

8. Describe the maintenance procedures that are typically performed on a Ross Furnace?

- Regular inspections of the furnace, including the refractory lining, burners, and other components.

- Repairs or replacements of faulty components as needed.

- Cleaning of the furnace to remove slag and other debris buildup.

- Calibration of instruments and sensors to ensure accurate operation.

9. Explain how you would handle a situation where the Ross Furnace is malfunctioning?

- I would first assess the situation and identify the potential cause of the malfunction.

- I would then follow established troubleshooting procedures to resolve the issue.

- If the issue cannot be resolved immediately, I would contact a qualified technician for assistance.

- I would also document the malfunction and any corrective actions taken.

10. Describe how you would optimize the efficiency of a Ross Furnace?

- Ensuring proper charging techniques and maintaining optimal furnace temperature.

- Regularly monitoring and adjusting the fuel-to-air ratio to achieve efficient combustion.

- Minimizing heat loss through proper insulation and maintenance of the furnace structure.

- Implementing preventive maintenance measures to reduce downtime and extend the life of the furnace.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ross Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ross Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ross Furnace Operators play a crucial role in the safe and efficient operation of Ross furnaces. Some of the key responsibilities of this role include:

1. Monitoring and Controlling Furnace Operations

Operating and monitoring the Ross furnace, including starting, stopping, and adjusting temperature and atmosphere settings.

Maintaining accurate records of furnace operating parameters and keeping a log of all activities related to the furnace.

2. Loading and Unloading Materials

Loading and unloading materials into and out of the furnace using appropriate tools and equipment.

Ensuring that materials are properly placed and secured within the furnace to prevent damage or accidents.

3. Troubleshooting and Maintenance

Performing basic troubleshooting and maintenance tasks on the furnace, such as replacing filters and cleaning components.

Identifying potential problems and promptly reporting any malfunctions or safety concerns to the supervisor.

4. Maintaining a Safe Work Environment

Observing all safety protocols and regulations related to the operation of the furnace.

Wearing appropriate personal protective equipment, such as gloves, safety glasses, and protective clothing.

Interview Tips

Preparing thoroughly for an interview is crucial to making a positive impression and increasing your chances of success. Here are some helpful tips to assist you in acing your Ross Furnace Operator interview:

1. Research the Company and Position

Take the time to thoroughly research the company and the Ross Furnace Operator position. This will demonstrate your interest in the opportunity and show the interviewer that you have a clear understanding of the role.

2. Practice Your Answers to Common Interview Questions

Some common interview questions that you may encounter include: “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?” Prepare concise and well-thought-out answers to these and other anticipated questions.

3. Highlight Your Relevant Experience and Skills

Emphasize your relevant experience and skills that align with the job requirements. For instance, mention any experience you have operating furnaces, handling materials, or performing maintenance tasks.

4. Prepare Questions to Ask the Interviewer

Preparing questions to ask the interviewer demonstrates your engagement and curiosity about the role and the company. This also gives you the opportunity to clarify any uncertainties and show your interest in the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ross Furnace Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ross Furnace Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.