Are you gearing up for an interview for a Rotary Adjuster position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rotary Adjuster and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

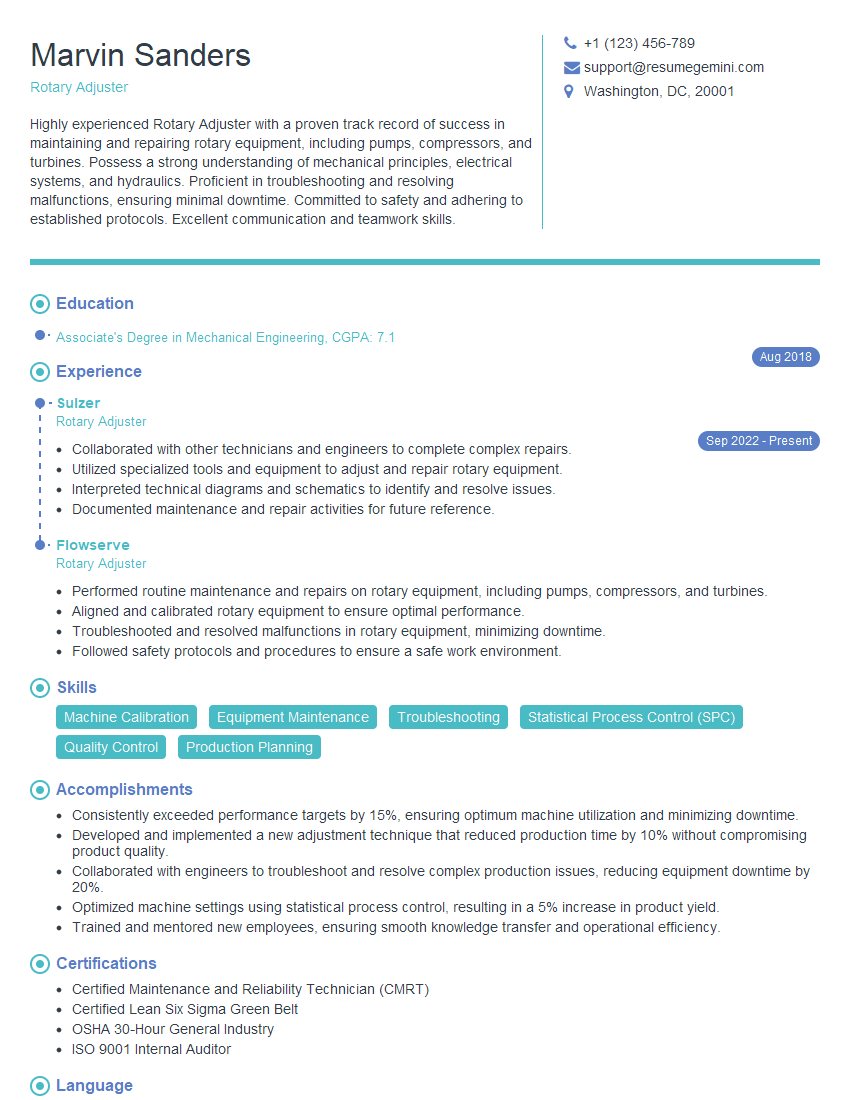

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Adjuster

1. Explain the primary responsibilities of a Rotary Adjuster

As a Rotary Adjuster, I would be responsible for:

- Performing precision adjustments to rotary equipment, using specialized tools and measuring instruments.

- Inspecting, diagnosing, and troubleshooting rotary equipment malfunctions.

- Installing, replacing, and repairing rotary equipment components.

- Maintaining and calibrating rotary equipment.

- Ensuring that rotary equipment meets safety standards and operational specifications.

2. Describe the key skills required for success in this role.

Technical Skills:

- Thorough understanding of rotary equipment principles and operation.

- Expertise in precision measurement and adjustment techniques.

- Proficiency in troubleshooting and diagnosing rotary equipment malfunctions.

- Knowledge of electrical, mechanical, and hydraulic systems.

Soft Skills:

- Strong attention to detail and accuracy.

- Excellent problem-solving and analytical skills.

- Ability to work independently and as part of a team.

- Exceptional communication and interpersonal skills.

3. How do you stay up-to-date on the latest rotary equipment advancements?

I stay up-to-date on the latest rotary equipment advancements through:

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Networking with other rotary equipment professionals.

- Participating in training programs offered by manufacturers and industry organizations.

4. Can you describe a complex rotary equipment repair you have performed?

In my previous role, I was tasked with repairing a high-speed centrifugal compressor that had experienced a catastrophic bearing failure. I:

- Disassembled the compressor and inspected all components.

- Analyzed the bearing failure and determined the root cause.

- Replaced the damaged bearings and seals.

- Reassembled the compressor and performed precision adjustments.

- Tested the compressor and confirmed its performance met specifications.

5. How do you ensure the accuracy of your adjustments?

I ensure the accuracy of my adjustments by:

- Using high-precision measuring instruments and tools.

- Following established procedures and standards.

- Double-checking my work and obtaining independent verification when necessary.

- Calibrating my measuring instruments regularly.

6. What are some of the safety precautions you take when working with rotary equipment?

The safety precautions I take when working with rotary equipment include:

- Ensuring that all equipment is properly locked out and tagged out before performing any work.

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection.

- Inspecting equipment for any potential hazards before starting work.

- Following all established safety protocols and procedures.

- Being aware of the potential hazards associated with rotating machinery.

7. How do you prioritize your workload when faced with multiple tasks?

I prioritize my workload by:

- Assessing the urgency and importance of each task.

- Creating a prioritized task list.

- Delegating tasks to others when appropriate.

- Focusing on completing one task at a time.

- Communicating my progress and any potential delays to my supervisor.

8. Can you tell me about a time when you had to troubleshoot a complex rotary equipment issue?

In my previous role, a critical pump was experiencing excessive vibration. I:

- Collected data from sensors and performed vibration analysis.

- Inspected the pump components and identified loose bolts as the root cause.

- Tightened the bolts and performed a vibration test to confirm the issue was resolved.

9. What is your experience with using computer-aided design (CAD) software for rotary equipment?

I am proficient in using CAD software for rotary equipment. I use CAD to:

- Create and modify 3D models of rotary equipment components.

- Analyze and optimize equipment designs.

- Generate engineering drawings for manufacturing.

10. How do you stay motivated and productive in a fast-paced environment?

I stay motivated and productive in a fast-paced environment by:

- Setting clear goals and priorities.

- Breaking down large tasks into smaller, manageable steps.

- Taking breaks and managing my time effectively.

- Rewarding myself for my accomplishments.

- Maintaining a positive attitude and focusing on the importance of my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotary Adjusters, also known as Rotary Die Adjusters, play a pivotal role in manufacturing and production operations. They are responsible for setting up, adjusting, and maintaining rotary die-cutting machines used in the creation of a wide range of products, including packaging, labels, and other components.

1. Machine Setup and Adjustment

Rotary Adjusters are tasked with the precise setup and calibration of rotary die-cutting machines. This involves:

- Installing and aligning rotary dies onto the machine

- Adjusting cutting pressures, speeds, and other parameters to ensure optimal performance

- Verifying machine functionality and ensuring proper alignment of dies to produce high-quality products

2. Die Maintenance and Repair

Rotary Adjusters are responsible for the maintenance and repair of the dies used in rotary die-cutting operations. They conduct regular inspections, identify any potential issues, and perform necessary repairs to ensure the longevity and efficiency of the dies.

3. Quality Control

Ensuring the quality of products produced on rotary die-cutting machines is a key responsibility of Rotary Adjusters. They perform ongoing inspections to monitor product quality, identify any defects, and make necessary adjustments to the machine or dies.

4. Troubleshooting and Problem-Solving

Rotary Adjusters are often called upon to troubleshoot and resolve problems that may arise during production. This includes:

- Identifying and addressing machine malfunctions

- Diagnosing product defects and determining the root cause

- Implementing solutions to minimize downtime and ensure smooth production operations

Interview Tips

Preparing for an interview for a Rotary Adjuster position requires careful planning and preparation. Here are some tips to help candidates ace their interview:

1. Research the Company and Position

Thoroughly research the company and the specific Rotary Adjuster position you are applying for. This will allow you to gain a deeper understanding of the company’s values, culture, and the specific responsibilities of the role.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Focus on your technical expertise in rotary die-cutting, as well as your problem-solving and troubleshooting abilities.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your responses in advance. This will help you feel more confident and articulate during the actual interview. Examples of common interview questions for Rotary Adjusters include:

- “Describe your experience in setting up and adjusting rotary die-cutting machines.”

- “How do you troubleshoot and resolve common problems encountered in rotary die-cutting operations?”

- “What steps do you take to ensure product quality and minimize defects?”

4. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the Rotary Adjuster role and the manufacturing industry. Show that you are genuinely interested in the company and the position, and express your eagerness to contribute to the team’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotary Adjuster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!