Are you gearing up for a career in Rotary Cutter Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rotary Cutter Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

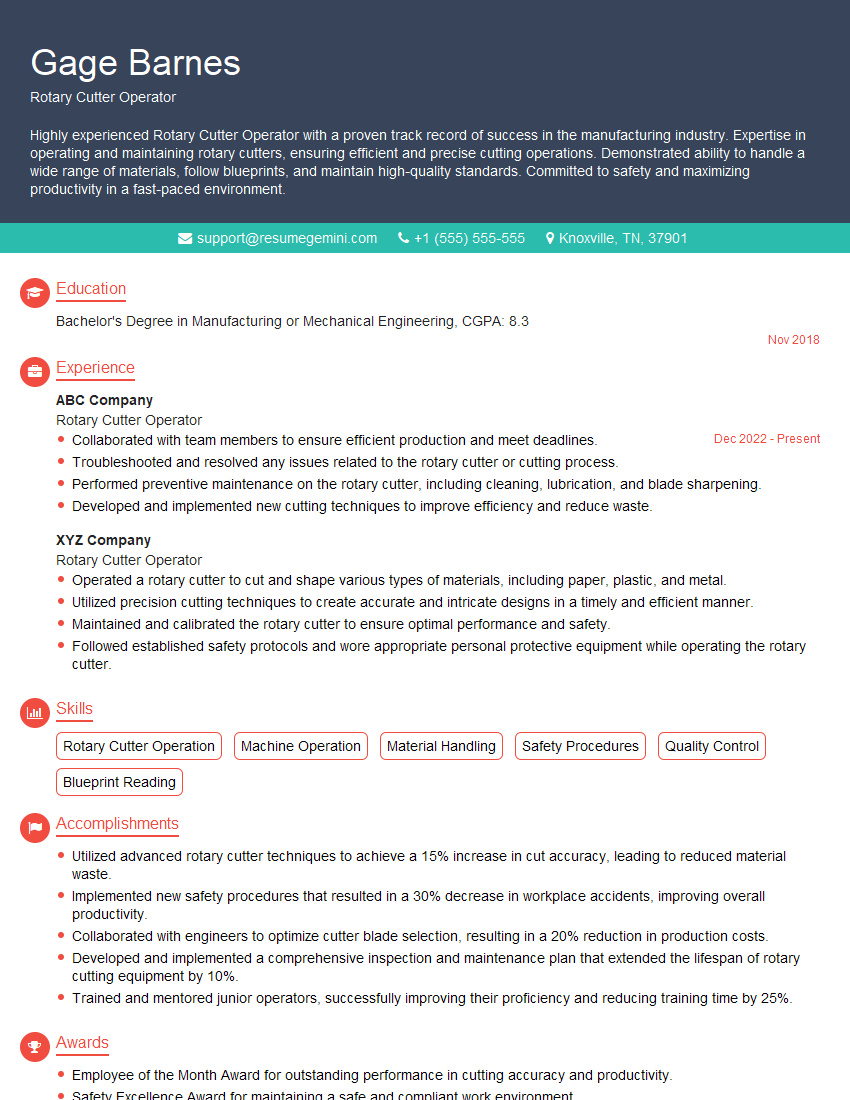

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Cutter Operator

1. What are the key responsibilities of a Rotary Cutter Operator?

As a Rotary Cutter Operator, I would be responsible for:

- Operating and maintaining rotary cutting machines to cut and shape a variety of materials.

- Setting up and adjusting the machine according to specifications.

- Monitoring the cutting process and making adjustments as needed.

- Inspecting the finished products to ensure they meet quality standards.

- Maintaining a clean and safe work area.

- Following all safety procedures and regulations.

- Working as part of a team to achieve production goals.

2. How do you ensure the accuracy of cuts made with a rotary cutter?

To ensure accuracy, I follow these steps:

- Proper machine setup: I carefully set up the machine according to the specified cutting parameters, including blade type, speed, and feed rate.

- Accurate measurements: I use precision measuring tools to mark and measure the material before cutting to ensure precise alignment.

- Sharp blades: I use sharp blades that are regularly inspected and replaced to maintain optimal cutting performance and prevent tearing or fraying of the material.

- Stable cutting surface: I ensure that the material is securely placed on a stable surface to prevent movement during cutting.

- Careful operation: I operate the machine with care and precision, paying attention to the cutting path and making smooth, controlled movements.

3. What types of materials can you cut using a rotary cutter?

I have experience cutting a wide range of materials, including:

- Paper and cardboard

- Fabrics and textiles

- Leather and faux leather

- Thin plastics and films

- Foil and other metallic materials

- Gaskets and seals

- Composite materials

4. How do you troubleshoot common problems that may arise during rotary cutting?

Some common problems and troubleshooting steps include:

- Uneven or inaccurate cuts: I check the blade sharpness, machine settings, and material alignment to identify and correct any issues.

- Tearing or fraying of material: I inspect the blade for dullness or damage, adjust the cutting pressure, and ensure the material is supported properly.

- Machine overheating: I check for proper ventilation, inspect the motor and bearings for wear, and ensure the machine is not overloaded.

- Excessive noise or vibration: I inspect the machine for loose or damaged parts, check the blade balance, and adjust the cutting speed or feed rate as needed.

5. What safety precautions are essential when operating a rotary cutter?

I strictly adhere to the following safety precautions:

- Proper attire: I wear appropriate clothing, safety glasses, and gloves to protect myself from debris and potential hazards.

- Guarding: I ensure that all machine guards and safety devices are in place and functioning correctly.

- Blade handling: I handle blades with care, store them securely, and dispose of them properly.

- Electrical safety: I follow proper lockout/tagout procedures, inspect electrical cords and connections, and ground the machine as required.

- Machine maintenance: I perform regular maintenance and inspections to keep the machine in good working condition.

6. How do you maintain a rotary cutter for optimal performance?

To maintain optimal performance, I perform the following tasks:

- Regular cleaning: I clean the machine thoroughly after each use to remove debris and prevent buildup.

- Blade inspection and sharpening: I regularly inspect the blade for wear or damage and sharpen it as needed.

- Lubrication: I lubricate moving parts according to the manufacturer’s recommendations.

- Belt and tension checks: I check the belts for wear and tension and adjust them as necessary.

- Calibration: I periodically calibrate the machine to ensure accurate cutting.

7. What techniques do you use to minimize waste and optimize material usage?

To minimize waste and optimize material usage, I employ the following techniques:

- Efficient cutting patterns: I plan and optimize cutting patterns to minimize material waste by utilizing nesting and other techniques.

- Multiple-pass cutting: For thick or dense materials, I use multiple passes with adjusted cutting depth to reduce waste and achieve cleaner cuts.

- Material handling: I handle materials carefully to prevent damage or tearing, which can lead to waste.

- Scrap management: I collect and organize scrap materials for reuse or recycling.

8. How do you stay updated with the latest industry best practices and technological advancements in rotary cutting?

To stay updated, I:

- Attend industry conferences and workshops: I participate in events that showcase new technologies and best practices.

- Read industry publications and online resources: I subscribe to trade magazines and follow online forums to stay informed about industry trends.

- Network with other professionals: I connect with peers and experts in the field to exchange knowledge and learn about innovations.

- Attend manufacturer training sessions: I take advantage of training opportunities offered by rotary cutter manufacturers to enhance my skills and knowledge.

9. How do you handle working in a fast-paced, high-volume production environment?

In fast-paced environments, I maintain efficiency and accuracy by:

- Prioritizing tasks: I plan my workload and prioritize tasks based on urgency and importance.

- Time management: I effectively manage my time, utilizing techniques such as time blocking and delegation.

- Organization: I maintain a well-organized workspace and keep necessary tools and materials readily accessible.

- Teamwork: I collaborate effectively with team members to share workload and support each other during peak periods.

10. Can you describe a situation where you had to troubleshoot a complex problem with a rotary cutter?

In a previous role, I encountered an issue where the rotary cutter was producing uneven cuts. I followed a systematic troubleshooting process:

- Inspection: I thoroughly inspected the blade, belts, and other components for any visible damage or wear.

- Calibration: I recalibrated the machine according to the manufacturer’s specifications.

- Material analysis: I examined the material being cut to ensure it met the required specifications for thickness and consistency.

- Blade adjustment: I adjusted the blade angle and pressure to optimize cutting performance.

Through this process, I identified that the blade needed to be replaced due to excessive wear. After replacing the blade, the machine operated smoothly and produced consistent, high-quality cuts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Cutter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Cutter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotary Cutter Operators are responsible for operating and maintaining rotary cutters, which are used to cut and shape metal and other materials. They must have a strong understanding of the machine’s operation and be able to make adjustments as needed. Key job responsibilities include:

1. Operate Rotary Cutter

Rotary Cutter Operators must be able to operate the rotary cutter safely and efficiently. This includes setting up the machine, loading and unloading materials, and making adjustments as needed. They must also be able to identify and troubleshoot any problems that may arise.

- Set up and operate rotary cutter according to specifications.

- Load and unload materials onto the cutter bed.

- Monitor the cutting process and make adjustments as needed.

2. Maintain Rotary Cutter

Rotary Cutter Operators must be able to maintain the rotary cutter in good working condition. This includes cleaning the machine, lubricating moving parts, and replacing worn or damaged parts. They must also be able to identify and troubleshoot any problems that may arise.

- Clean and lubricate the rotary cutter regularly.

- Inspect the cutter for worn or damaged parts.

- Replace worn or damaged parts as needed.

3. Inspect Finished Product

Rotary Cutter Operators must be able to inspect the finished product to ensure that it meets specifications. This includes checking the dimensions, finish, and quality of the cut. They must also be able to identify any defects that may need to be corrected.

- Inspect finished products to ensure they meet specifications.

- Identify and correct any defects.

- Package and label finished products.

4. Follow Safety Procedures

Rotary Cutter Operators must be able to follow all safety procedures when operating the rotary cutter. This includes wearing appropriate safety gear, such as safety glasses, gloves, and a hard hat. They must also be aware of the potential hazards of the machine and take steps to avoid accidents.

- Follow all safety procedures when operating the rotary cutter.

- Wear appropriate safety gear, such as safety glasses, gloves, and a hard hat.

- Be aware of the potential hazards of the machine and take steps to avoid accidents.

Interview Tips

To ace the interview for a Rotary Cutter Operator position, it is important to be prepared. Here are some tips:

1. Research the Company and the Position

Take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the position.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company, if possible.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Use the STAR method to answer interview questions.

- Be specific and provide examples from your experience.

- Practice your answers out loud so that you can deliver them confidently.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience operating rotary cutters. Be prepared to talk about your skills and knowledge in this area. You can also highlight any specific projects or accomplishments that you are proud of.

- Quantify your experience whenever possible.

- Use action verbs to describe your skills and accomplishments.

- Be prepared to discuss your experience in detail.

4. Ask Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. It is also a chance to show the interviewer that you are interested and engaged.

- Ask thoughtful questions about the company, the position, and the industry.

- Don’t be afraid to ask for clarification if you don’t understand something.

- Thank the interviewer for their time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rotary Cutter Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.